Table of Contents

How to Choose the Right Zinc Wire Manufacturer for Your Business

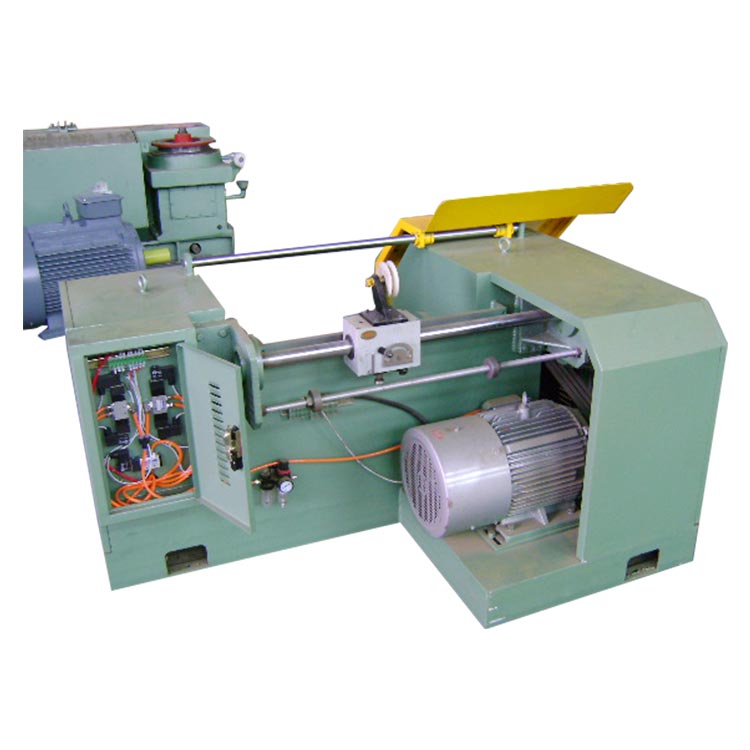

When it comes to choosing a Pure Zinc Wire Drawing Machine manufacturer for your business, there are several factors to consider in order to ensure that you are getting the best quality product at the most competitive price. Zinc wire is a crucial component in many industries, including automotive, construction, and electronics, so it is important to choose a manufacturer that can meet your specific needs and requirements.

One of the first things to consider when choosing a zinc wire manufacturer is the quality of their products. It is important to choose a manufacturer that uses high-quality materials and follows strict quality control measures to ensure that their products meet industry standards. Look for manufacturers that have certifications or accreditations that demonstrate their commitment to quality.

In addition to quality, it is also important to consider the manufacturer’s production capacity and lead times. Make sure that the manufacturer has the capacity to meet your production needs and can deliver products in a timely manner. This is especially important if you have tight deadlines or need to ramp up production quickly.

Another important factor to consider when choosing a zinc wire manufacturer is their pricing. While it is important to find a manufacturer that offers competitive pricing, it is also important to consider the overall value that they provide. Look for manufacturers that offer a good balance of quality and price, and be wary of manufacturers that offer prices that seem too good to be true, as this may indicate lower quality products.

It is also important to consider the manufacturer’s reputation and track record. Look for manufacturers that have a proven track record of delivering high-quality products and excellent customer service. You can research a manufacturer’s reputation by reading reviews and testimonials from other customers, as well as by checking their references.

When choosing a Fine Wire Drawing Machine For Zinc Wire manufacturer, it is also important to consider their customer service and support. Look for manufacturers that are responsive to your inquiries and are willing to work with you to meet your specific needs. Good communication is key when working with a manufacturer, so make sure that they are easy to reach and are willing to provide updates on your order status.

In conclusion, choosing the right zinc wire manufacturer for your business is a crucial decision that can have a significant impact on the quality and success of your products. By considering factors such as quality, production capacity, pricing, reputation, and customer service, you can ensure that you are choosing a manufacturer that meets your specific needs and requirements. Take the time to research and evaluate potential manufacturers before making a decision, and don’t be afraid to ask questions or request samples to ensure that you are making the best choice for your business.

Benefits of Using Zinc Wire in Industrial Applications

Zinc wire is a versatile material that has a wide range of industrial applications. From galvanizing steel to protecting against corrosion, zinc wire offers numerous benefits that make it a popular choice for many industries. In this article, we will explore the advantages of using zinc wire in industrial applications.

One of the primary benefits of using zinc wire is its ability to protect against corrosion. Zinc is a highly reactive metal that forms a protective layer on the surface of steel when applied as a coating. This layer acts as a barrier, preventing moisture and other corrosive elements from reaching the underlying steel. As a result, zinc-coated steel is highly resistant to rust and corrosion, making it ideal for outdoor applications where exposure to the elements is a concern.

In addition to its corrosion-resistant properties, zinc wire is also known for its high conductivity. This makes it an excellent choice for applications where electrical conductivity is important, such as in the production of electrical components and wiring. Zinc wire can be easily formed into various shapes and sizes, making it a versatile material that can be used in a wide range of industrial applications.

Another benefit of using zinc wire is its affordability. Zinc is a relatively inexpensive material compared to other metals, making it a cost-effective option for many industrial applications. Despite its low cost, zinc wire offers excellent performance and durability, making it a popular choice for manufacturers looking to reduce production costs without sacrificing quality.

Zinc wire is also environmentally friendly, as it is a fully recyclable material. This makes it a sustainable choice for manufacturers looking to reduce their environmental impact and comply with regulations regarding waste disposal. By using zinc wire in their production processes, companies can reduce their carbon footprint and contribute to a more sustainable future.

Furthermore, zinc wire is easy to work with and can be easily integrated into existing manufacturing processes. Whether it is used for coating steel or producing electrical components, zinc wire can be easily shaped, cut, and welded to meet the specific requirements of each application. This flexibility makes zinc wire a versatile material that can be adapted to a wide range of industrial processes.

In conclusion, zinc wire offers numerous benefits for industrial applications, including corrosion resistance, high conductivity, affordability, sustainability, and ease of use. Whether it is used for protecting against rust, improving electrical conductivity, or reducing production costs, zinc wire is a versatile material that can enhance the performance and efficiency of manufacturing processes. By choosing zinc wire for their industrial applications, companies can benefit from its many advantages and contribute to a more sustainable and cost-effective production process.