Wire Straightening and Cutting Machines in China

Wire straightening and cutting machines have become an essential tool in the manufacturing industry, especially in China. These machines are designed to straighten and cut wires quickly and accurately, saving time and labor costs. In this article, we will explore the benefits of using wire straightening and cutting machines in China.

One of the main advantages of using wire straightening and cutting machines is their efficiency. These machines are capable of straightening and cutting wires at a much faster rate than manual methods. This increased speed allows manufacturers to produce more products in a shorter amount of time, ultimately increasing their overall productivity.

In addition to speed, wire straightening and cutting machines also offer a high level of accuracy. These machines are equipped with advanced technology that ensures wires are cut to the exact length and straightness required for each specific application. This precision is crucial in industries such as construction, automotive, and electronics, where even the slightest deviation in wire length or straightness can lead to product defects.

Furthermore, using wire straightening and cutting machines can help reduce material waste. Manual wire cutting methods often result in uneven cuts and wasted material. In contrast, wire straightening and cutting machines are programmed to optimize material usage, minimizing waste and saving manufacturers money in the long run.

Another benefit of using wire straightening and cutting machines is the reduction of labor costs. By automating the wire cutting process, manufacturers can significantly reduce the need for manual labor, saving on labor costs and increasing overall efficiency. This is particularly beneficial in China, where labor costs are rising, and manufacturers are looking for ways to streamline their operations.

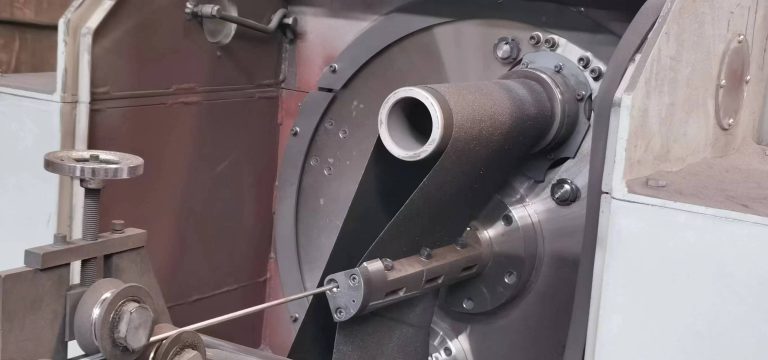

Moreover, wire straightening and cutting machines are versatile and can handle a wide range of wire diameters and materials. This flexibility allows manufacturers to use the same machine for different types of wires, eliminating the need for multiple machines and reducing equipment costs. Additionally, these machines can be easily adjusted to accommodate different wire lengths and cutting angles, making them suitable for a variety of applications.

In conclusion, wire straightening and cutting machines offer numerous benefits to manufacturers in China. From increased efficiency and accuracy to reduced material waste and labor costs, these machines are a valuable asset in the manufacturing industry. By investing in wire straightening and cutting machines, manufacturers can improve their productivity, reduce costs, and stay competitive in the global market.