Table of Contents

Advanteges of Using Wire Pointing Machines in Construction Projects

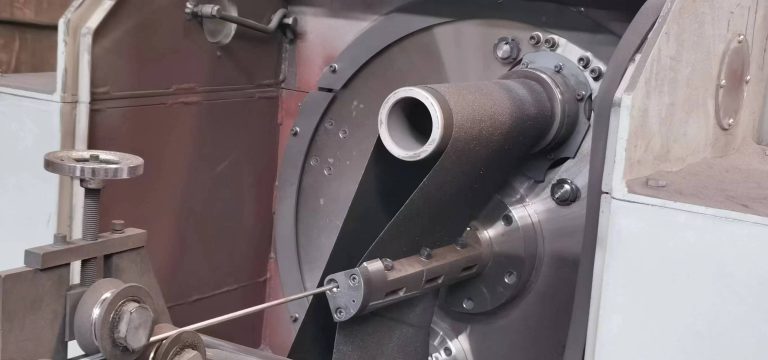

Wire pointing machines are essential tools in the construction industry, providing numerous advantege to contractors and workers alike. These machines are designed to accurately and efficiently point the ends of wires, making them easier to insert into concrete or other materials. In this article, we will explore the various advantages of using a wire pointing machine in construction projects.

One of the primary benefits of using a wire pointing machine is the time and labor savings it offers. By automating the process of pointing wires, these machines can significantly reduce the amount of time and effort required to prepare materials for construction. This allows workers to focus on other tasks, increasing overall productivity on the job site.

In addition to saving time and labor, Wire Drawing Pointing Machine also help improve the quality and consistency of the finished product. By ensuring that wires are properly pointed, these machines help prevent issues such as misalignment or weak connections, which can compromise the structural integrity of a building. This results in a higher quality end product that is built to last.

Another advantage of using a wire pointing machine is the increased safety it provides on the job site. Manual wire pointing can be a hazardous task, requiring workers to use sharp tools and exert significant force to properly point the wires. By automating this process, wire pointing machines help reduce the risk of injuries and accidents, creating a safer work environment for everyone involved.

Furthermore, wire pointing machines are versatile tools that can be used in a variety of construction projects. Whether you are working on a small residential build or a large commercial development, these machines can help streamline the wire pointing process, saving time and improving efficiency across the board. This versatility makes wire pointing machines a valuable investment for any construction company.

Additionally, using a wire pointing machine can help reduce waste on the job site. By accurately pointing wires to the correct length, these machines help minimize material waste, saving both time and money in the long run. This not only benefits the bottom line of the construction project but also helps reduce the environmental impact of the construction process.

Overall, wire pointing machines offer a wide range of benefits to construction projects, from saving time and labor to improving safety and quality. By automating the wire pointing process, these machines help increase efficiency, reduce waste, and create a safer work environment for everyone involved. Whether you are a contractor looking to improve productivity on the job site or a worker seeking to streamline your workflow, a wire pointing machine is a valuable tool that can help you achieve your goals.

How to Choose the Right Wire Pointing Machine for Your Business

Wire pointing machines are essential tools for businesses that work with wire materials. These machines are used to remove burrs and sharp edges from wire ends, making them smooth and ready for further processing. Choosing the right wire pointing machine for your business is crucial to ensure efficiency and quality in your operations.

When selecting a wire pointing machine, there are several factors to consider. The first thing to look at is the type of wire materials you will be working with. Different machines are designed to handle specific types of wire, so it is important to choose a machine that is compatible with the materials you will be using.

Another important factor to consider is the size of the wire you will be working with. Wire pointing machines come in a variety of sizes to accommodate different wire diameters. It is important to choose a machine that can handle the size of wire you will be processing to ensure optimal performance.

In addition to the type and size of wire, you should also consider the production capacity of the machine. Some wire pointing machines are designed for high-volume production, while others are better suited for smaller-scale operations. It is important to choose a machine that can meet the production demands of your business to avoid delays and inefficiencies.

The quality of the wire pointing machine is also an important consideration. Look for machines that are made from high-quality materials and are built to last. A durable machine will require less maintenance and repairs, saving you time and money in the long run.

When choosing a wire pointing machine, it is also important to consider the features and capabilities of the machine. Some machines come with additional features such as automatic feeding and cutting, which can help streamline your operations and improve efficiency. Consider your specific needs and requirements when selecting a machine to ensure it meets your business needs.

It is also important to consider the reputation of the manufacturer when choosing a wire pointing machine. Look for manufacturers with a proven track record of producing high-quality machines that are reliable and efficient. Reading reviews and testimonials from other businesses can help you gauge the quality of the machine and the level of customer satisfaction.

Finally, consider the cost of the wire pointing machine. While it is important to invest in a high-quality machine, it is also important to consider your budget and choose a machine that offers the best value for your money. Compare prices from different manufacturers and consider the long-term costs of maintenance and repairs when making your decision.

In conclusion, choosing the right wire pointing machine for your business is essential to ensure efficiency and quality in your operations. Consider factors such as the type and size of wire, production capacity, quality, features, manufacturer reputation, and cost when selecting a machine. By taking the time to research and evaluate your options, you can find a wire pointing machine that meets your business needs and helps you achieve success in your operations.