Table of Contents

Common Wire Pointing Techniques for Wire Drawing Machines

Wire pointing is a crucial process in the wire drawing industry, as it helps to ensure the smooth and efficient operation of wire drawing machines. By properly Wire Pointing Machine the wire before it enters the drawing die, manufacturers can reduce the risk of breakage and improve the overall quality of the finished product. There are several common wire pointing techniques that are used in wire drawing machines, each with its own advantages and disadvantages.

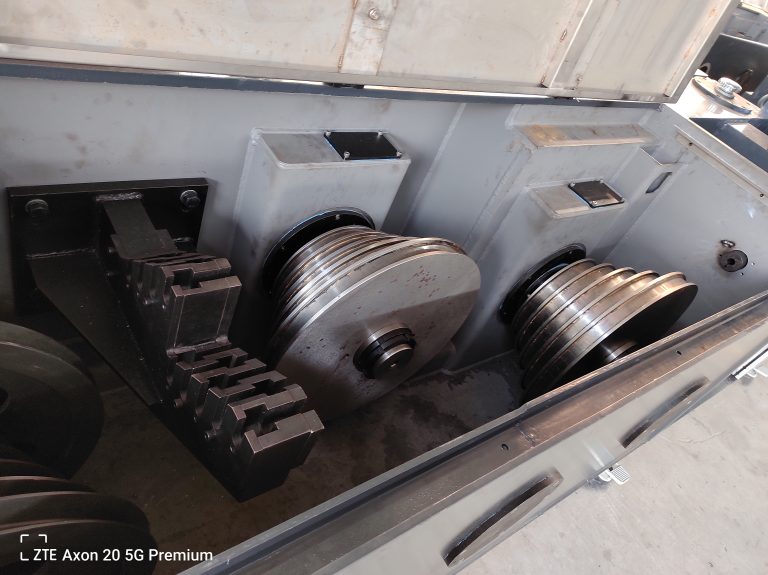

One of the most common wire pointing techniques is the use of a wire pointing machine. This machine is designed to straighten and point the wire before it enters the drawing die, ensuring that it is properly aligned and ready for the drawing process. Wire pointing machines can be either manual or automatic, with automatic machines being more commonly used in high-volume production settings.

Another common wire pointing technique is the use of a wire pointing die. This die is used to shape the end of the wire into a point, making it easier to feed into the drawing die. Wire pointing dies can be made from a variety of materials, including carbide and diamond, depending on the specific requirements of the wire being drawn.

In addition to wire pointing machines and dies, some manufacturers also use wire pointing tools such as pliers or hammers to manually point the wire before it enters the drawing die. While this method is less precise than using a machine or die, it can be effective for smaller production runs or for wires that require a more customized pointing process.

Regardless of the specific wire pointing technique used, it is important to ensure that the wire is properly pointed before it enters the drawing die. This will help to prevent breakage and ensure that the wire is drawn smoothly and efficiently. In addition, properly pointed wire will result in a higher-quality finished product, with fewer defects and imperfections.

When choosing a wire pointing technique for a wire drawing machine, manufacturers should consider the specific requirements of their production process, as well as the type of wire being drawn. Some wire pointing techniques may be more suitable for certain types of wire or production volumes, so it is important to carefully evaluate the options before making a decision.

Overall, wire pointing is an essential process in the wire drawing industry, and choosing the right wire pointing technique can have a significant impact on the efficiency and quality of the wire drawing process. By properly pointing the wire before it enters the drawing die, manufacturers can ensure that their wire drawing machines operate smoothly and produce high-quality wire products.

Benefits of Wire Pointing for Improving Wire Drawing Machine Efficiency

Wire pointing is a crucial process in the wire drawing industry that plays a significant role in improving the efficiency of wire drawing machines. By pointing the wire before it enters the drawing machine, manufacturers can achieve a smoother and more consistent wire surface, resulting in higher quality end products. In this article, we will explore the benefits of improving Wire Drawing Pointing Machine efficiency.

One of the primary benefits of wire pointing is the reduction of material waste. When wire is not properly pointed before entering the drawing machine, it can cause uneven drawing and result in material being wasted. By pointing the wire, manufacturers can ensure that the wire is properly aligned and ready for the drawing process, reducing the amount of material that is wasted during production.

Additionally, wire pointing helps to improve the overall efficiency of the wire drawing machine. When wire is pointed before entering the machine, it can move through the drawing process more smoothly and quickly. This results in a faster production time and increased output, ultimately leading to higher productivity and profitability for manufacturers.

Another benefit of wire pointing is the improvement of wire quality. When wire is properly pointed before entering the drawing machine, it can result in a smoother and more consistent wire surface. This can lead to higher quality end products that meet the specifications and requirements of customers. By pointing the wire, manufacturers can ensure that their products are of the highest quality and meet industry standards.

Furthermore, wire pointing can help to extend the life of wire drawing machine components. When wire is not properly pointed before entering the machine, it can cause excessive wear and tear on the drawing dies and other components. This can lead to increased maintenance costs and downtime for manufacturers. By pointing the wire, manufacturers can reduce the amount of stress and strain on the machine components, ultimately extending their lifespan and reducing maintenance costs.

In conclusion, wire pointing is a critical process in the wire drawing industry that offers a wide range of benefits for manufacturers. From reducing material waste and improving efficiency to enhancing wire quality and extending the life of machine components, wire pointing plays a crucial role in improving the overall efficiency of wire drawing machines. By investing in wire pointing technology, manufacturers can achieve higher productivity, increased profitability, and higher quality end products.