Maintenance Tips For Nail Making Machine

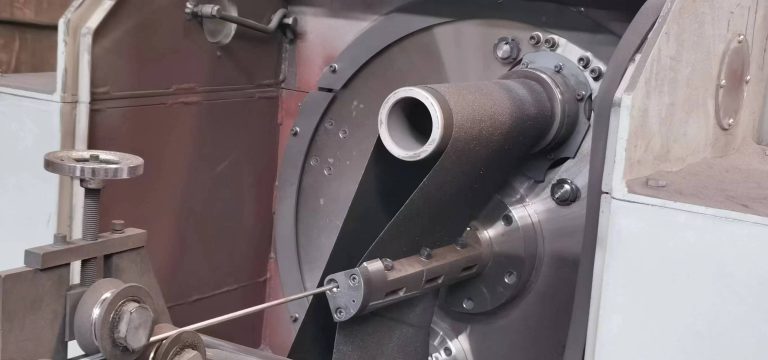

Wire Nail Making Machine is essential tools in the manufacturing industry, as they automate the process of creating nails quickly and efficiently. To ensure that these machines continue to operate at their best, regular maintenance is crucial. By following a few simple tips, you can extend the lifespan of your nail making machine and prevent costly repairs.

One of the most important maintenance tasks for nail making machines is keeping them clean. Dust, debris, and metal shavings can build up in the machine over time, causing it to malfunction. Regularly cleaning the machine with a soft brush and compressed air can help prevent these issues. Additionally, lubricating moving parts with a high-quality oil can reduce friction and wear, prolonging the life of the machine.

Another key maintenance tip is to regularly inspect the machine for any signs of wear or damage. Check for loose or worn parts, such as belts, gears, and bearings, and replace them as needed. It is also important to check the alignment of the machine to ensure that all components are working together properly. Making these small adjustments can prevent larger problems down the line.

In addition to regular cleaning and inspections, it is important to follow the manufacturer’s recommended maintenance schedule. This may include tasks such as replacing filters, adjusting tension settings, and calibrating the machine. By staying on top of these routine maintenance tasks, you can prevent unexpected breakdowns and keep your nail making machine running smoothly.

When performing maintenance on a High Speed Nail Making Machine, it is important to follow proper safety procedures. Always turn off the machine and disconnect it from power before performing any maintenance tasks. Wear appropriate protective gear, such as gloves and safety glasses, to prevent injury. If you are unsure how to perform a maintenance task, consult the machine’s manual or contact a professional technician for assistance.

In addition to regular maintenance, there are a few tips you can follow to ensure that your nail making machine operates at its best. Keep the machine in a clean, dry environment to prevent rust and corrosion. Store spare parts and tools in a designated area to keep them organized and easily accessible. And finally, train your operators on how to use the machine properly to prevent unnecessary wear and tear.

By following these maintenance tips, you can keep your nail making machine in top condition and avoid costly repairs. Regular cleaning, inspections, and lubrication can help prevent breakdowns and extend the lifespan of the machine. Following the manufacturer’s recommended maintenance schedule and proper safety procedures is essential to keeping the machine running smoothly. With a little care and attention, your nail making machine can continue to produce high-quality nails for years to come.