Table of Contents

understand of Using Different Lubricants in Wire Drawing Process

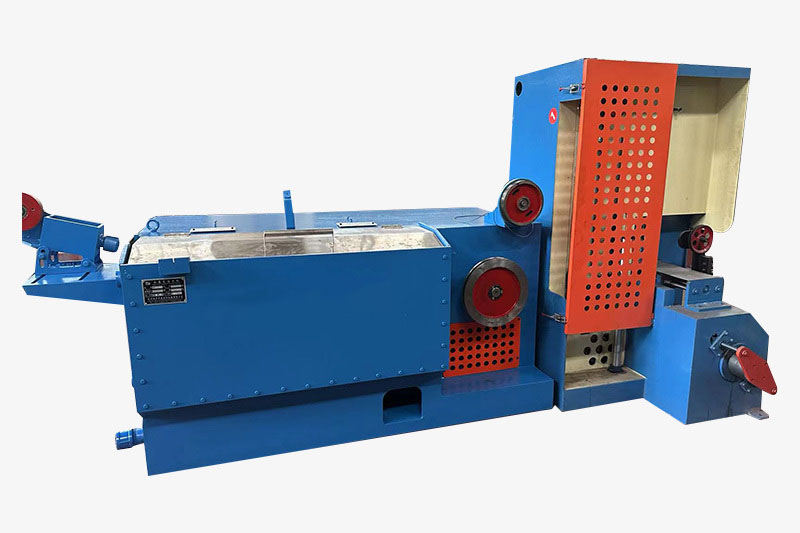

Wet Wire Drawing Machine is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One crucial aspect of the wire drawing process is the use of lubricants, which help reduce friction between the wire and the dies, making the process smoother and more efficient.

There are several benefits to using different types of lubricants in the wire drawing process. One of the primary advantages is that lubricants help reduce the amount of force required to pull the wire through the dies. This not only makes the process easier on the equipment but also helps extend the life of the dies, as less wear and tear occurs when the wire is properly lubricated. Additionally, using the right lubricant can help improve the surface finish of the wire, resulting in a smoother and more uniform product.

Different types of lubricants can be used in the wire drawing process, depending on the specific requirements of the application. One common type of lubricant is oil-based lubricants, which are typically used for drawing softer metals such as aluminum or copper. These lubricants provide excellent lubrication and cooling properties, making them ideal for reducing friction and heat during the drawing process.

Another type of lubricant that is commonly used in wire drawing is soap-based lubricants. These lubricants are typically used for drawing harder metals such as steel or stainless steel. Soap-based lubricants provide excellent lubrication properties and help reduce friction between the wire and the dies, making the drawing process smoother and more efficient.

In addition to oil-based and soap-based lubricants, there are also synthetic lubricants that can be used in the wire drawing process. Synthetic lubricants are often preferred for their superior lubrication properties and ability to withstand high temperatures. These lubricants are ideal for drawing high-strength materials or for applications where extreme temperatures are involved.

Choosing the right lubricant for the wire drawing process is essential for achieving optimal results. The type of lubricant used will depend on factors such as the material being drawn, the size of the wire, and the speed of the drawing process. It is important to work closely with lubricant suppliers to determine the best lubricant for your specific application and to ensure that the lubricant is applied correctly to achieve the desired results.

In conclusion, using different types of lubricants in the wire drawing process offers several benefits, including reducing friction, extending the life of the dies, and improving the surface finish of the wire. By choosing the right lubricant for your specific application, you can ensure that the wire drawing process is smooth, efficient, and produces high-quality results. Working with lubricant suppliers to determine the best lubricant for your needs is essential for achieving optimal results in the wire drawing process.

Common Wire Drawing Defects and How to Prevent Them

Wire drawing machine for aluminum wire is a crucial process in the manufacturing of various types of wire products, including electrical wiring, cables, and fencing. This process involves pulling a metal wire through a series of dies to reduce its diameter and improve its mechanical properties. While wire drawing is a well-established technique, it is not without its challenges. Common wire drawing defects can occur during the process, leading to substandard wire products that may not meet quality standards. In this article, we will discuss some of the most common wire drawing defects and how they can be prevented.

One of the most common wire drawing defects is surface cracking. Surface cracks can occur due to excessive friction between the wire and the die, leading to localized stress concentrations that cause the wire to crack. To prevent surface cracking, it is essential to ensure that the wire is properly lubricated during the drawing process. Lubricants help reduce friction between the wire and the die, preventing excessive heat buildup and stress concentrations that can lead to cracking. Additionally, using dies with smooth surfaces and proper surface finishes can help reduce the risk of surface cracking.

Another common wire drawing defect is die wear. Dies are subjected to high levels of stress and wear during the wire drawing process, leading to gradual degradation of their surface quality. As dies wear out, they can produce rough surfaces on the wire, leading to increased friction and potential defects. To prevent die wear, it is essential to regularly inspect and maintain the dies used in the wire drawing process. Dies should be replaced or resurfaced as needed to ensure that they maintain their proper shape and surface finish.

Inconsistent wire diameter is another common wire drawing defect that can occur due to variations in the drawing process. Inconsistent wire diameter can lead to issues such as poor electrical conductivity or mechanical strength in the final wire product. To prevent inconsistent wire diameter, it is essential to carefully control the drawing process parameters, such as drawing speed, die geometry, and lubrication. By maintaining tight control over these parameters, manufacturers can ensure that the wire produced meets the required specifications for diameter and mechanical properties.

One of the most challenging wire drawing defects to prevent is internal cracking. Internal cracks can occur due to a variety of factors, including material impurities, excessive drawing speed, or improper die design. Internal cracks are particularly problematic because they are not visible on the surface of the wire and can only be detected through destructive testing methods. To prevent internal cracking, it is essential to carefully control the drawing process parameters and ensure that the wire material is free from impurities that can lead to cracking. Additionally, using dies with proper design and surface finishes can help reduce the risk of internal cracking.

In conclusion, wire drawing is a complex process that requires careful attention to detail to produce high-quality wire products. By understanding the common wire drawing defects and taking proactive measures to prevent them, manufacturers can ensure that their wire products meet the required quality standards. Proper lubrication, die maintenance, control over process parameters, and material quality are all essential factors in preventing wire drawing defects and producing high-quality wire products. By implementing these preventive measures, manufacturers can improve the efficiency and reliability of their wire drawing processes, leading to better overall product quality and customer satisfaction.