Table of Contents

How to Choose the Right Wire Drawing Pointing Machines for Your Needs

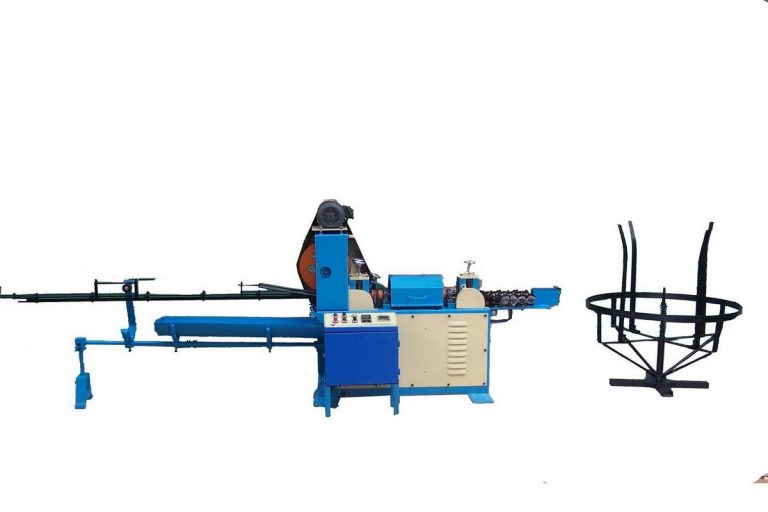

Wire drawing pointing machine is essential tools in the wire manufacturing industry. These machines are used to straighten and point wires, making them suitable for further processing or use in various applications. Choosing the right wire drawing pointing machine for your needs is crucial to ensure efficient and high-quality wire production.

When selecting a wire drawing pointing machine, there are several factors to consider. The first consideration is the type of wire you will be processing. Different machines are designed to handle specific wire diameters and materials. It is important to choose a machine that is capable of handling the size and type of wire you will be working with.

Another important factor to consider is the production capacity of the machine. If you have a high volume of wire to process, you will need a machine that can handle large quantities efficiently. On the other hand, if you have a smaller operation, a machine with lower production capacity may be sufficient.

The accuracy and precision of the machine are also crucial considerations. A wire drawing pointing machine that can consistently produce straight and pointed wires within tight tolerances is essential for ensuring the quality of your products. Look for machines that are equipped with advanced technology and features that allow for precise wire processing.

Ease of operation and maintenance are also important factors to consider when choosing a wire drawing pointing machine. A machine that is easy to set up, operate, and maintain will help streamline your production process and minimize downtime. Look for machines that are user-friendly and come with clear instructions and support from the manufacturer.

Cost is another important consideration when choosing a wire drawing pointing machine. While it is important to invest in a high-quality machine that meets your production needs, it is also important to consider your budget. Compare prices from different manufacturers and suppliers to find a machine that offers the best value for your money.

When researching wire drawing pointing machines, be sure to read reviews and testimonials from other users. This can provide valuable insights into the performance and reliability of different machines. Additionally, consider reaching out to manufacturers or suppliers directly to ask any questions you may have and to get more information about their products.

In conclusion, choosing the right wire drawing pointing machine for your needs is essential for ensuring efficient and high-quality wire production. Consider factors such as the type of wire you will be processing, production capacity, accuracy and precision, ease of operation and maintenance, cost, and user reviews when making your decision. By taking the time to research and compare different machines, you can find a machine that meets your requirements and helps you achieve your production goals.

Benefits of Using Wire Drawing Pointing Machine

Wire drawing pointing machines are essential tools in the wire manufacturing industry. These machines are used to straighten and point wires, making them suitable for further processing. There are several benefits to using a wire drawing pointing machine, which we will explore in this article.

One of the main advantages of using a wire drawing pointing machine is the ability to increase productivity. These machines are designed to process wires quickly and efficiently, saving time and labor costs. By automating the wire pointing process, manufacturers can produce more wires in less time, leading to higher output and increased profitability.

In addition to improving productivity, wire drawing pointing machines also help to enhance the quality of the finished product. These machines are equipped with precision tools that ensure the wires are straightened and pointed accurately. This results in wires that are uniform in size and shape, which is essential for applications where consistency is key.

Another benefit of using a wire drawing pointing machine is the reduction of waste. When wires are manually pointed, there is a higher risk of errors and inconsistencies, leading to a higher rate of rejected or scrapped wires. By using a wire drawing pointing machine, manufacturers can minimize waste and improve overall efficiency.

Furthermore, wire drawing pointing machines are versatile tools that can be used for a wide range of wire sizes and materials. Whether you are working with steel, aluminum, copper, or other materials, these machines can be adjusted to accommodate different wire diameters and specifications. This flexibility makes them a valuable asset for manufacturers who work with various types of wires.

Additionally, wire drawing pointing machines are easy to operate and maintain. Most machines are equipped with user-friendly controls that allow operators to adjust settings and monitor the process with ease. Regular maintenance and servicing can help prolong the lifespan of the machine and ensure consistent performance over time.

Overall, the benefits of using a wire drawing pointing machine are clear. From increasing productivity and improving quality to reducing waste and enhancing versatility, these machines offer a range of advantages for wire manufacturers. By investing in a wire drawing pointing machine, manufacturers can streamline their production process, achieve higher efficiency, and deliver high-quality wires to their customers.

In conclusion, wire drawing pointing machines are essential tools for the wire manufacturing industry. Their ability to increase productivity, enhance quality, reduce waste, and offer versatility make them valuable assets for manufacturers. By incorporating these machines into their production process, manufacturers can improve efficiency, consistency, and overall performance.

Maintenance Tips for Wire Drawing Pointing Machine

Wire drawing pointing machines are essential equipment in the wire manufacturing industry. These machines are used to straighten and point wires before they are further processed into various products. To ensure the efficient operation of a wire drawing pointing machine, regular maintenance is crucial. In this article, we will discuss some maintenance tips for wire drawing pointing machines to help you keep your equipment in top condition.

One of the most important maintenance tasks for a Wire Pointing Machine is to regularly inspect and clean the machine. Over time, dust, dirt, and debris can accumulate on the machine, affecting its performance. It is essential to clean the machine regularly to prevent any build-up that could lead to malfunctions. Use a soft brush or cloth to remove any dirt and debris from the machine, paying special attention to the wire feeding and pointing mechanisms.

In addition to cleaning, it is also important to lubricate the moving parts of the wire drawing pointing machine. Proper lubrication helps reduce friction and wear on the machine, extending its lifespan. Be sure to use the recommended lubricants for each part of the machine and follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricating the machine will help keep it running smoothly and prevent breakdowns.

Another crucial maintenance task for wire drawing pointing machines is to inspect and replace worn or damaged parts. Over time, the components of the machine can wear out or become damaged, affecting its performance. Regularly inspecting the machine for signs of wear and tear, such as loose or broken parts, can help prevent more significant issues from occurring. Replace any worn or damaged parts promptly to keep the machine operating efficiently.

It is also essential to check the tension of the wire being fed into the machine regularly. Improper wire tension can lead to issues such as wire breakage or misalignment, affecting the quality of the pointed wire. Adjust the tension settings as needed to ensure that the wire is fed smoothly into the machine and pointed accurately. Regularly monitoring the wire tension will help prevent production delays and ensure consistent product quality.

Additionally, it is important to calibrate the machine regularly to ensure accurate pointing of the wire. Over time, the machine’s calibration can drift, leading to inaccuracies in the pointing process. Calibrating the machine at regular intervals will help maintain the quality and consistency of the pointed wire. Follow the manufacturer’s guidelines for calibration procedures and schedule to ensure that the machine is operating correctly.

In conclusion, proper maintenance of wire drawing pointing machines is essential to ensure their efficient operation and longevity. Regular cleaning, lubrication, inspection, and part replacement are crucial tasks to keep the machine running smoothly. Monitoring wire tension and calibrating the machine regularly will help maintain the quality and accuracy of the pointed wire. By following these maintenance tips, you can keep your wire drawing pointing machine in top condition and avoid costly repairs or downtime.