Table of Contents

How to Choose the Right Wire Drawing Machine for Your Business

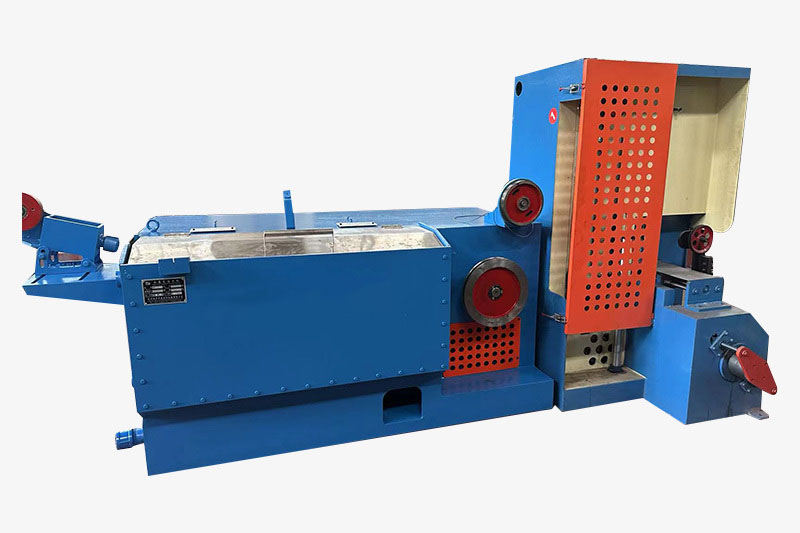

Wet Wire Drawing Machine is essential equipment for businesses that work with metal wires. These machines are used to reduce the diameter of a wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. Choosing the right wire drawing machine for your business is crucial to ensure efficiency and quality in your wire production process.

When selecting a wire drawing machine, there are several factors to consider. The first consideration is the type of wire you will be working with. Different wire drawing machines are designed for specific types of wire, such as steel, copper, or aluminum. It is important to choose a machine that is compatible with the material you will be using to ensure optimal performance.

Another important factor to consider is the size and capacity of the wire drawing machine. The size of the machine should be appropriate for the volume of wire production in your business. If you have a high production volume, you will need a machine with a larger capacity to handle the workload efficiently. On the other hand, if you have a smaller business with lower production volume, a smaller machine may be more suitable.

The speed of the wire drawing machine is also an important consideration. The speed at which the wire is drawn through the dies will determine the quality and efficiency of the process. A machine with adjustable speed settings can provide flexibility in production and allow for different wire diameters to be produced.

In addition to the type, size, and speed of the machine, it is important to consider the quality and durability of the wire drawing machine. Look for machines made from high-quality materials that are built to last. A durable machine will require less maintenance and repair, saving you time and money in the long run.

It is also important to consider the reputation of the manufacturer when choosing a wire drawing machine. Look for manufacturers with a proven track record of producing high-quality machines that meet industry standards. Reading reviews and testimonials from other businesses that have used the machine can help you make an informed decision.

When choosing a wire drawing machine, it is important to consider your budget. Wire drawing machines can vary in price depending on their size, capacity, and features. It is important to find a machine that fits within your budget while still meeting your production needs.

In conclusion, choosing the right wire drawing machine for your business is essential to ensure efficiency and quality in your wire production process. Consider factors such as the type of wire, size and capacity of the machine, speed, quality, and durability, as well as the reputation of the manufacturer. By carefully evaluating these factors and staying within your budget, you can select a wire drawing machine that will meet your business needs and help you achieve success in wire production.

Maintenance Tips to Keep Your Wire Drawing Machine Running Smoothly

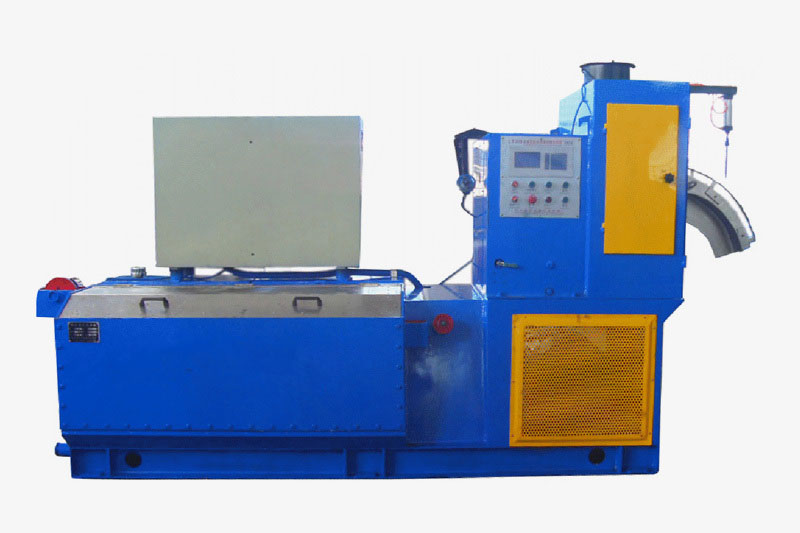

Wire drawing machines are essential tools in the manufacturing industry, used to produce wires of various diameters and lengths. These machines are complex pieces of equipment that require regular maintenance to ensure they run smoothly and efficiently. In this article, we will discuss some maintenance tips to help you keep your wire drawing machine in top condition.

One of the most important maintenance tasks for wire drawing machines is regular cleaning. Dust, dirt, and debris can build up on the machine’s components, causing them to wear out faster and reducing the machine’s efficiency. It is important to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the machine’s moving parts with a high-quality lubricant can help reduce friction and prevent premature wear.

Another important maintenance task is inspecting the machine’s components for signs of wear or damage. Check the machine’s rollers, dies, and other components regularly for any signs of wear, such as cracks, dents, or scratches. If you notice any damage, it is important to replace the affected parts as soon as possible to prevent further damage to the machine.

In addition to regular cleaning and inspection, it is important to calibrate the machine regularly to ensure it is producing wires of the correct diameter and length. Use a micrometer or other measuring device to check the diameter of the wires produced by the machine and make any necessary adjustments to the machine’s settings to ensure it is producing wires within the specified tolerances.

Proper storage of the machine when not in use is also important for maintaining its performance. Store the machine in a clean, dry environment away from dust, dirt, and moisture. Cover the machine with a protective cover when not in use to prevent dust and debris from accumulating on its components.

Regularly monitoring the machine’s performance can help you identify any issues before they become major problems. Keep track of the machine’s production output, speed, and any unusual noises or vibrations. If you notice any changes in the machine’s performance, it is important to investigate the issue and address it promptly to prevent further damage to the machine.

In conclusion, regular maintenance is essential for keeping your wire drawing machine running smoothly and efficiently. By following these maintenance tips, you can help extend the life of your machine and ensure it continues to produce high-quality wires for years to come. Remember to clean the machine regularly, inspect its components for signs of wear, calibrate it regularly, store it properly, and monitor its performance to keep it in top condition. With proper maintenance, your wire drawing machine will continue to be a valuable asset in your manufacturing operations.

Benefits of Using Wire Drawing Machines in Industrial Applications

Wire drawing machines are essential tools in the industrial sector for producing high-quality wire products. These machines are used to reduce the diameter of wire by pulling it through a series of dies, resulting in a smoother surface finish and improved mechanical properties. There are several benefits to using wire drawing machines in industrial applications, including increased productivity, cost savings, and improved product quality.

One of the primary advantages of using wire drawing machines is the significant increase in productivity. These machines are capable of processing large quantities of wire in a short amount of time, allowing manufacturers to meet production demands more efficiently. By automating the wire drawing process, companies can reduce labor costs and minimize the risk of human error, resulting in higher output and faster turnaround times.

In addition to increased productivity, wire drawing machines also offer cost savings for industrial applications. By using these machines, manufacturers can reduce material waste and optimize the use of raw materials, leading to lower production costs. Furthermore, the consistent and precise nature of wire drawing machines ensures that each wire product meets the required specifications, reducing the likelihood of defects and rework. This not only saves money but also improves overall product quality and customer satisfaction.

Another benefit of using wire drawing machines is the improved product quality that they provide. These machines are designed to produce wire with a smooth surface finish and precise dimensions, resulting in wire products that are stronger, more durable, and have better electrical conductivity. By using wire drawing machines, manufacturers can ensure that their products meet the highest industry standards and are suitable for a wide range of applications, from electrical wiring to automotive components.

Overall, wire drawing machines play a crucial role in the industrial sector by providing increased productivity, cost savings, improved product quality, and versatility. By investing in these machines, manufacturers can streamline their production processes, reduce waste, and deliver high-quality wire products to their customers. With the numerous benefits that wire drawing machines offer, it is clear that they are essential tools for any industrial application that requires precision wire processing.