Understanding the Wire Drawing Machine Process

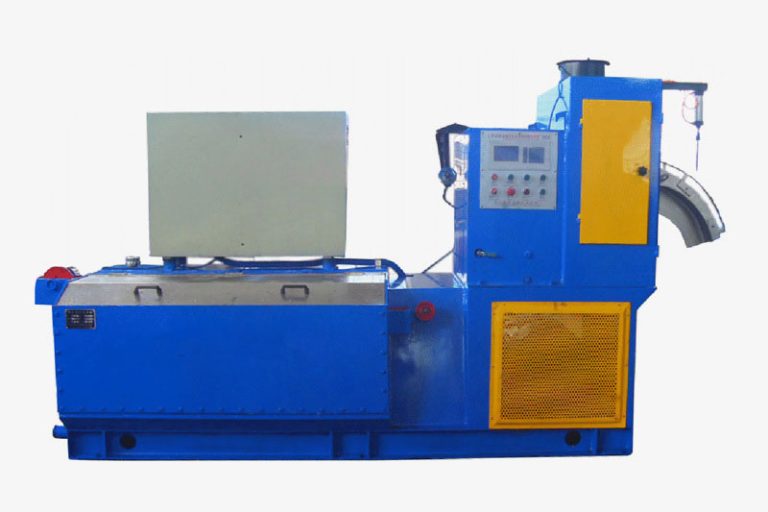

Straight Line Wire Drawing Machine is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wire, including steel, copper, and aluminum. The wire drawing machine is a key component in this process, as it is responsible for pulling the wire through the dies to achieve the desired diameter.

The wire drawing machine consists of several components that work together to reduce the diameter of the wire. The first component is the capstan, which is a rotating drum that pulls the wire through the dies. The capstan is powered by a motor, which controls the speed at which the wire is drawn through the machine. The dies are another important component of the wire drawing machine, as they are responsible for shaping the wire as it passes through them.

The wire drawing process begins by feeding a coil of wire into the machine. The wire is then passed through a series of dies, each with a slightly smaller diameter than the previous one. As the wire passes through the dies, it is stretched and reduced in diameter. This process is repeated multiple times until the wire reaches the desired diameter.

One of the key factors in the wire drawing process is the reduction ratio, which is the ratio of the initial wire diameter to the final wire diameter. The reduction ratio determines how many times the wire must pass through the dies to achieve the desired diameter. A higher reduction ratio requires more passes through the dies, resulting in a finer wire.

The wire drawing machine is equipped with various controls that allow operators to adjust the speed and tension of the wire as it passes through the machine. These controls are essential for ensuring that the wire is drawn evenly and consistently, resulting in a high-quality finished product.

In addition to controlling the speed and tension of the wire, operators must also monitor the condition of the dies. Over time, the dies can wear out and become damaged, which can affect the quality of the wire being produced. Regular maintenance and replacement of the dies are essential for ensuring that the wire drawing machine operates efficiently and produces high-quality wire.

Overall, the wire drawing machine process is a complex and precise operation that requires careful control and monitoring. By understanding the components of the wire drawing machine and how they work together, manufacturers can produce high-quality wire for a variety of applications. Proper maintenance and operation of the wire drawing machine are essential for achieving consistent results and meeting the demands of the market.