Table of Contents

understanding of Wire Drawing Machine in Industrial Applications

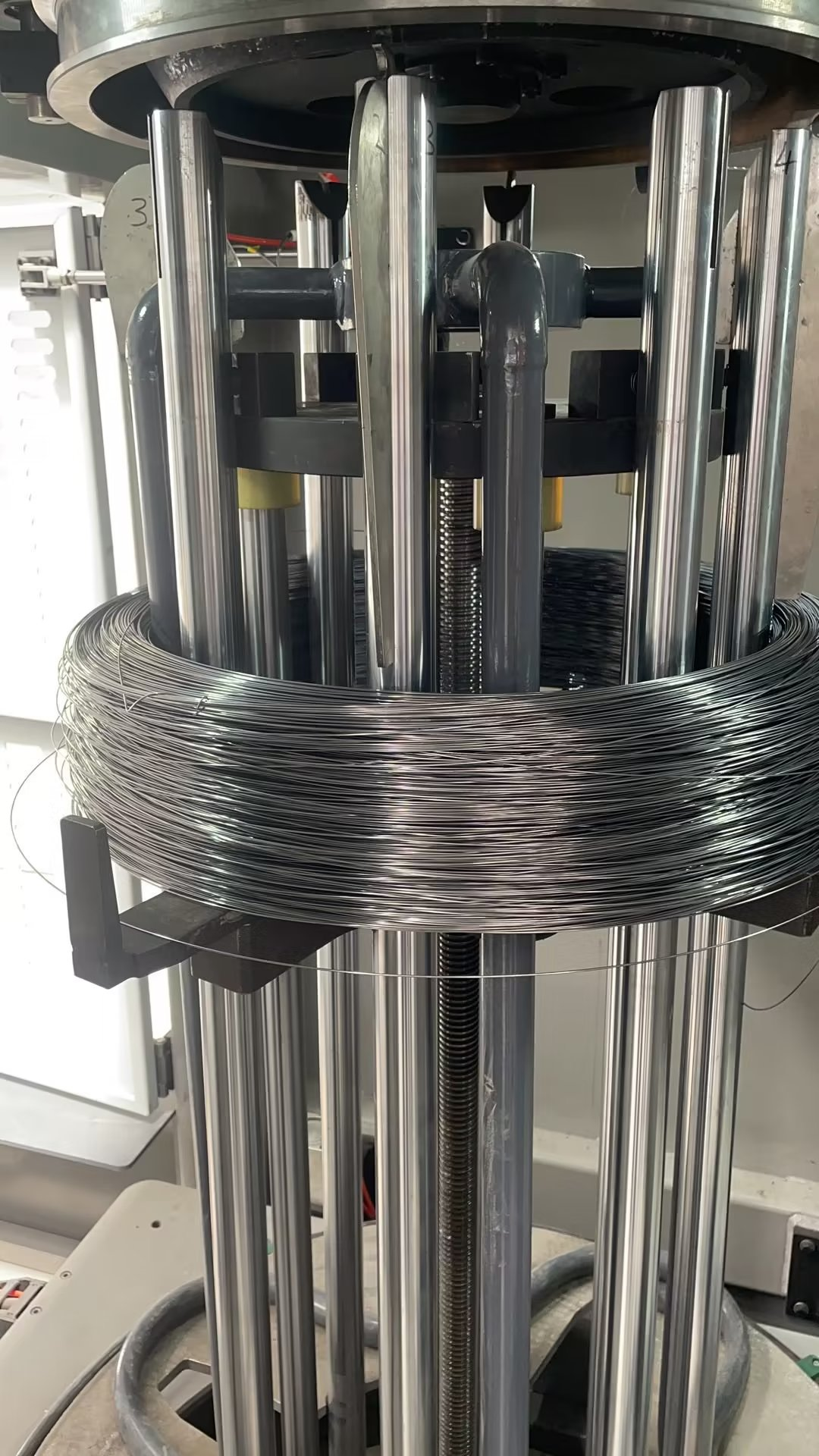

Wire drawing machines are essential tools in the industrial sector for producing wires of various diameters and lengths. These machines are used in a wide range of industries, including automotive, construction, electronics, and telecommunications. The process of wire drawing involves pulling a metal rod or wire through a series of dies to reduce its diameter and increase its length. This results in a smoother, stronger, and more uniform wire that is suitable for a variety of applications.

One of the key benefits of using a Straight Line Wire Drawing Machine is the ability to produce wires with precise dimensions. These machines are equipped with multiple dies that can be adjusted to achieve the desired diameter and length of the wire. This level of precision is crucial in industries where consistency and accuracy are paramount, such as in the production of electrical cables or automotive components.

Another advantage of using a wire drawing machine is the ability to control the mechanical properties of the wire. By adjusting the speed and tension of the machine, manufacturers can tailor the strength, ductility, and hardness of the wire to meet specific requirements. This flexibility allows for the production of wires that are optimized for their intended use, whether it be for structural support, electrical conductivity, or thermal insulation.

In addition to producing wires with precise dimensions and mechanical properties, wire drawing machines also offer increased efficiency and productivity. These machines are capable of processing large volumes of material in a relatively short amount of time, making them ideal for high-volume production environments. By automating the wire drawing process, manufacturers can reduce labor costs, minimize material waste, and improve overall production output.

Furthermore, wire drawing machines are designed to operate continuously, with minimal downtime for maintenance or adjustments. This reliability ensures a consistent supply of high-quality wires, allowing manufacturers to meet customer demands and deadlines without interruption. Additionally, the durability and longevity of these machines make them a cost-effective investment for businesses looking to streamline their production processes and improve their bottom line.

In conclusion, wire drawing machines offer a wide range of benefits for industrial applications. From producing wires with precise dimensions and mechanical properties to increasing efficiency and productivity, these machines play a crucial role in the manufacturing sector. By investing in a wire drawing machine, businesses can enhance the quality of their products, reduce production costs, and stay competitive in today’s fast-paced market. Whether it be for automotive, construction, electronics, or telecommunications, the versatility and reliability of wire drawing machines make them an indispensable tool for modern industrial operations.

How to Choose the Right Wire Drawing Machine for Your Business

Wire drawing machines are essential equipment for businesses that work with metal wires. These machines are used to reduce the diameter of a wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. Choosing the right wire drawing machine for your business is crucial to ensure efficiency and quality in your production process.

When selecting a wire drawing machine, there are several factors to consider. The first consideration is the type of wire you will be working with. Different wire drawing machines are designed for specific types of wire, such as steel, copper, or aluminum. It is important to choose a machine that is compatible with the material you will be using to ensure optimal performance.

Another important factor to consider is the size and capacity of the wire drawing machine. The size of the machine should be appropriate for the volume of wire you will be processing. If you have a high production volume, you will need a machine with a larger capacity to handle the workload efficiently. On the other hand, if you have a smaller operation, a smaller machine may be sufficient.

The speed of the wire drawing machine is also an important consideration. The speed at which the wire is drawn through the dies will determine the final diameter of the wire. It is important to choose a machine with the appropriate speed for the type of wire you are working with and the desired diameter of the finished product.

In addition to these factors, it is important to consider the quality and reliability of the wire drawing machine. Look for a machine that is made from high-quality materials and is built to last. A reliable machine will help you avoid costly downtime and maintenance issues, ensuring smooth operation and consistent production.

When choosing a wire drawing machine, it is also important to consider the level of automation and control features. Some machines offer advanced automation features that can help improve efficiency and productivity. Look for a machine that offers easy-to-use controls and automation options that suit your production needs.

Finally, consider the cost of the wire drawing machine. While it is important to invest in a high-quality machine, it is also important to consider your budget and choose a machine that offers the best value for your money. Compare prices and features from different manufacturers to find a machine that meets your requirements and fits within your budget.

In conclusion, choosing the right wire drawing machine for your business is a crucial decision that can impact the efficiency and quality of your production process. Consider factors such as the type of wire, size and capacity, speed, quality and reliability, automation features, and cost when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your requirements, you can ensure smooth operation and consistent production in your business.