Benefits of Using a Wire Dead Block Coiler Machine

A wire dead block coiler machine is a valuable piece of equipment that offers numerous benefits to industries that rely on wire coiling processes. This machine is designed to efficiently coil wire onto a spool or reel, making it an essential tool for businesses that work with wire on a regular basis. In this article, we will explore the various benefits of using a wire dead block coiler machine.

One of the primary advantages of using a wire dead block coiler machine is its ability to increase productivity. This machine is capable of coiling wire at a much faster rate than manual coiling methods, allowing businesses to complete their wire coiling tasks in a fraction of the time. This increased efficiency can lead to cost savings and improved overall productivity for the business.

In addition to improving productivity, a wire dead block coiler machine also helps to ensure consistency in the coiling process. Manual coiling methods can result in uneven coils, which can lead to issues such as tangling or kinking in the wire. By using a machine to coil the wire, businesses can achieve consistent, high-quality coils every time, reducing the risk of defects and ensuring that the wire is ready for use as soon as it is coiled.

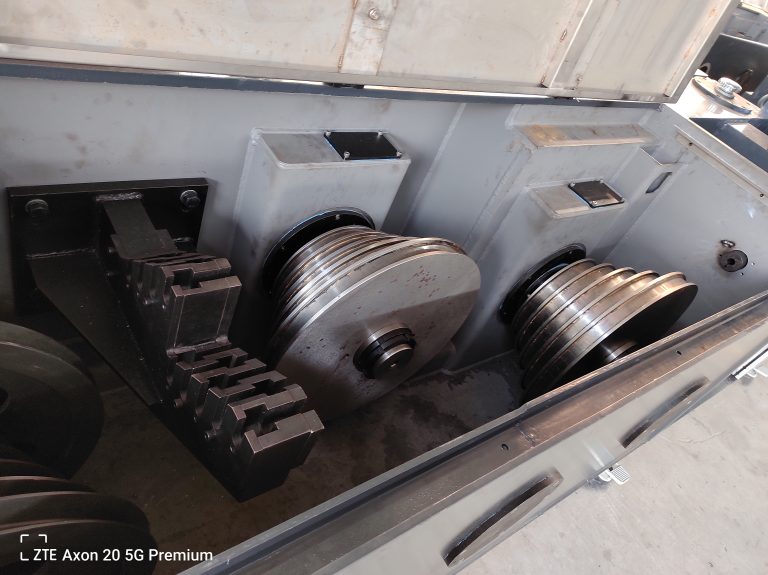

Another benefit of using a Horizontal Dead Block Wire Coiler machine is its ability to handle a wide range of wire sizes and types. These machines are designed to accommodate various wire diameters and materials, making them versatile tools for businesses that work with different types of wire. Whether you are working with thin, delicate wire or thick, heavy-duty wire, a wire dead block coiler machine can handle the job with ease.

Furthermore, a wire dead block coiler machine can help to improve workplace safety. Manual wire coiling can be a labor-intensive and potentially hazardous task, especially when working with heavy or sharp-edged wire. By using a machine to handle the coiling process, businesses can reduce the risk of injuries and create a safer working environment for their employees.

Additionally, a wire dead block coiler machine can help to reduce waste and minimize material loss. Manual coiling methods can result in wasted wire due to uneven coils or mistakes in the coiling process. By using a machine to coil the wire, businesses can minimize material loss and ensure that they are making the most of their resources.

Overall, a wire dead block coiler machine is a valuable investment for businesses that work with wire on a regular basis. From increasing productivity and ensuring consistency to improving workplace safety and reducing waste, the benefits of using a wire dead block coiler machine are numerous. By incorporating this machine into their operations, businesses can streamline their wire coiling processes and achieve better results in less time.