Table of Contents

The Wire Drawing Machine in Manufacturing Processes

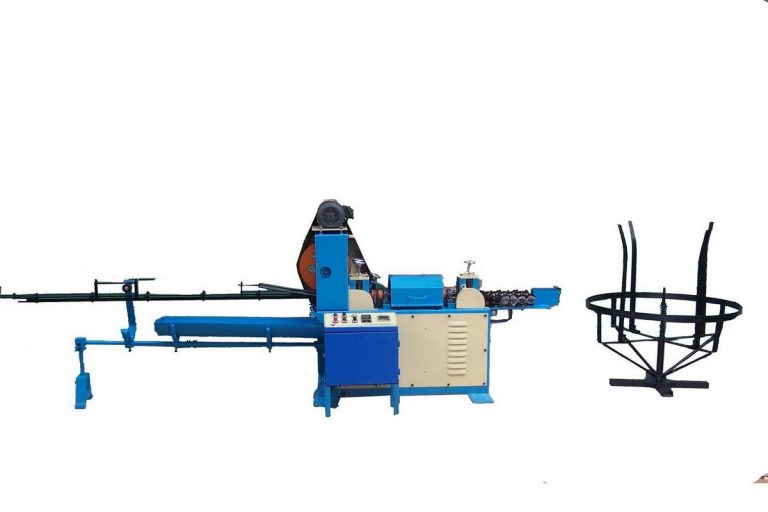

Wire drawing machines are essential tools in the manufacturing industry, particularly in the production of wires and cables. These machines are used to reduce the diameter of a wire by pulling it through a series of dies, resulting in a smoother and more uniform surface. The process involves drawing the wire through a die or series of dies to reduce its diameter and increase its length. This article will explore the benefits of using a wire drawing machine in manufacturing processes.

One of the primary benefits of using a Wet Wire Drawing Machine is the ability to produce wires of consistent diameter and quality. By controlling the speed and tension of the wire as it is drawn through the dies, manufacturers can ensure that the final product meets their specifications. This level of precision is crucial in industries such as electronics, where even minor variations in wire diameter can affect the performance of the end product.

Another advantage of using a wire drawing machine is the ability to work with a wide range of materials. These machines can handle various types of metals, including copper, aluminum, and steel, as well as alloys and other materials. This versatility makes wire drawing machines suitable for a wide range of applications, from electrical wiring to automotive components.

In addition to producing wires of consistent diameter, wire drawing machines can also improve the surface finish of the wire. As the wire is drawn through the dies, any imperfections or irregularities on the surface are smoothed out, resulting in a cleaner and more uniform finish. This can be particularly important in applications where the wire will be visible or where a smooth surface is necessary for proper functioning.

Wire drawing machines are also highly efficient, allowing manufacturers to produce large quantities of wire quickly and cost-effectively. By automating the drawing process, these machines can increase productivity and reduce labor costs. This efficiency is especially valuable in industries with high demand for wire products, such as construction, telecommunications, and automotive manufacturing.

Furthermore, wire drawing machines can help manufacturers reduce waste and improve sustainability. By producing wires with precise dimensions, manufacturers can minimize material loss and optimize the use of resources. This can lead to cost savings and environmental benefits, making wire drawing machines a valuable investment for companies looking to improve their sustainability practices.

Overall, the benefits of using a wire drawing machine in manufacturing processes are clear. From producing wires of consistent diameter and quality to improving surface finish and efficiency, these machines offer a range of advantages for manufacturers in various industries. By investing in a wire drawing machine, companies can enhance their production processes, increase productivity, and achieve higher levels of quality and precision in their wire products.

How to Choose the Right Wire Drawing Machine for Your Business

Wire drawing machines are essential tools in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. This process is crucial for producing wires of various sizes and shapes, which are used in a wide range of applications, from electrical wiring to construction materials. Choosing the right wire drawing machine for your business is a critical decision that can impact the quality and efficiency of your production process.

When selecting a Slip Wire Drawing Machine, there are several factors to consider. The first and most important factor is the type of wire you will be producing. Different types of wire drawing machines are designed for specific types of wire, such as steel, copper, or aluminum. It is essential to choose a machine that is compatible with the material you will be working with to ensure optimal performance and quality.

Another crucial factor to consider is the size and speed of the machine. The size of the machine will depend on the diameter of the wire you will be producing, while the speed will determine the production capacity of the machine. It is essential to choose a machine that can meet your production requirements while maintaining high quality standards.

Additionally, consider the number of dies and the die configuration of the machine. The number of dies will determine the number of passes the wire will make through the machine, while the die configuration will impact the final shape and size of the wire. It is essential to choose a machine with the right number of dies and die configuration to achieve the desired results.

Furthermore, consider the power and control system of the machine. A powerful motor is essential for driving the wire through the dies, while a reliable control system is necessary for adjusting the speed and tension of the wire. It is crucial to choose a machine with a robust power and control system to ensure smooth and efficient operation.

In addition to these factors, consider the reputation and reliability of the manufacturer. Choose a reputable manufacturer with a track record of producing high-quality wire drawing machines. A reliable manufacturer will provide excellent customer support and service, ensuring that your machine operates smoothly and efficiently.

In conclusion, choosing the right wire drawing machine for your business is a critical decision that can impact the quality and efficiency of your production process. Consider factors such as the type of wire, size and speed of the machine, number of dies and die configuration, power and control system, and the reputation of the manufacturer. By carefully evaluating these factors, you can select a wire drawing machine that meets your production requirements and helps you achieve success in your business.