Table of Contents

How to Choose the Right Wet Wire Drawing Machine for Your Business

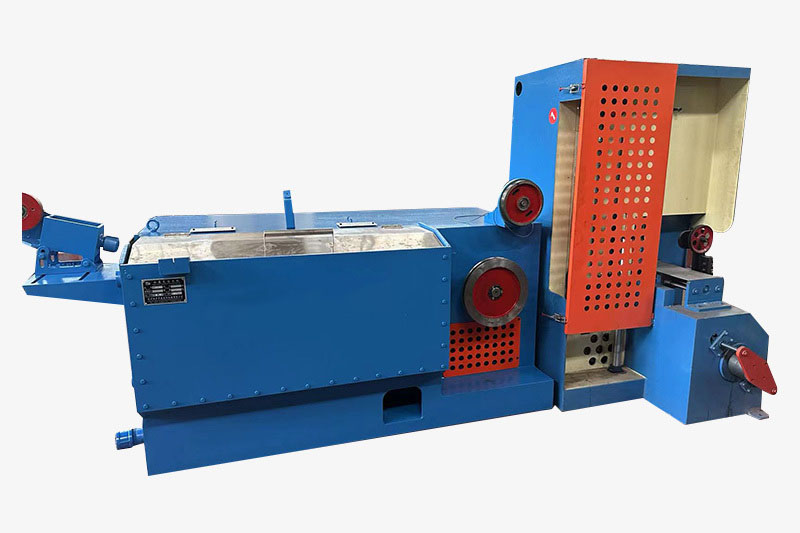

When it comes to choosing the right wet wire drawing machine for your business, there are several factors to consider. Wet wire drawing machines are used to reduce the diameter of wire by pulling it through a series of dies while using a lubricant to reduce friction and heat. This process is essential for producing high-quality wire with a smooth surface finish.

One of the first things to consider when selecting a wet wire drawing machine is the size and type of wire you will be working with. Different machines are designed to handle different wire diameters and materials, so it is important to choose a machine that is suitable for your specific needs. Additionally, consider the production capacity of the machine to ensure that it can meet the demands of your business.

Another important factor to consider is the number of dies on the machine. The number of dies will determine the number of passes the wire will make through the machine, which will ultimately affect the final diameter of the wire. Machines with more dies are capable of producing finer wire, while machines with fewer dies are better suited for larger diameter wire.

It is also important to consider the speed and power of the Slip Wire Drawing Machine. The speed at which the wire is drawn through the machine will affect the production rate, so it is important to choose a machine that can operate at the desired speed. Additionally, the power of the machine will determine its ability to handle the workload and produce consistent results.

When selecting a wet wire drawing machine, it is important to consider the quality of the machine and its components. Look for machines that are made from high-quality materials and have a reputation for reliability and durability. Additionally, consider the manufacturer of the machine and their reputation in the industry.

Cost is another important factor to consider when choosing a wet wire drawing machine. While it is important to stay within budget, it is also important to consider the long-term costs associated with the machine. Look for machines that offer a good balance of quality and affordability to ensure that you are getting the best value for your investment.

In conclusion, choosing the right wet wire drawing machine for your business is a crucial decision that requires careful consideration of several factors. By considering the size and type of wire, production capacity, number of dies, speed and power, quality, manufacturer reputation, and cost, you can select a machine that meets your specific needs and helps you achieve your production goals. Take the time to research and compare different machines to ensure that you are making the best choice for your business.

Benefits of Upgrading to a New Wet Wire Drawing Machine

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One of the key components in the wire drawing process is the wire drawing machine, which is responsible for pulling the wire through the dies to reduce its diameter.

If you are in the market for a new wire drawing machine, you may want to consider upgrading to a wet wire drawing machine. Wet wire drawing machines use a lubricant, such as oil or water, to reduce friction between the wire and the dies, resulting in a smoother and more efficient drawing process. There are several benefits to upgrading to a new wet wire drawing machine, including increased productivity, improved wire quality, and reduced maintenance costs.

One of the primary benefits of upgrading to a new wet wire drawing machine is increased productivity. Wet wire drawing machines are designed to operate at higher speeds than dry wire drawing machines, allowing you to produce more wire in less time. This can help you meet customer demand more efficiently and increase your overall production capacity. Additionally, the use of a lubricant in the drawing process can help reduce wear and tear on the dies, extending their lifespan and reducing the need for frequent replacements.

Another benefit of upgrading to a new wet wire drawing machine is improved wire quality. The lubricant used in wet wire drawing machines helps to cool the wire as it is being drawn, preventing overheating and reducing the risk of surface defects. This results in a smoother, more uniform wire with fewer imperfections, making it suitable for a wider range of applications. Additionally, the lubricant can help reduce the risk of breakage during the drawing process, resulting in a higher yield of usable wire.

In addition to increased productivity and improved wire quality, upgrading to a new wet wire drawing machine can also help reduce maintenance costs. The use of a lubricant in the drawing process can help reduce friction and wear on the dies, extending their lifespan and reducing the need for frequent maintenance. This can help lower your overall maintenance costs and downtime, allowing you to focus on other aspects of your business.

Overall, upgrading to a new wet wire drawing machine can offer a range of benefits for your manufacturing operation. From increased productivity and improved wire quality to reduced maintenance costs, a wet wire drawing machine can help you streamline your production process and improve the quality of your products. If you are in the market for a new wire drawing machine, consider upgrading to a wet wire drawing machine to take advantage of these benefits and enhance your manufacturing capabilities.