Table of Contents

Merits of Using a Wet Wire Drawing Machine For Aluminium Wire

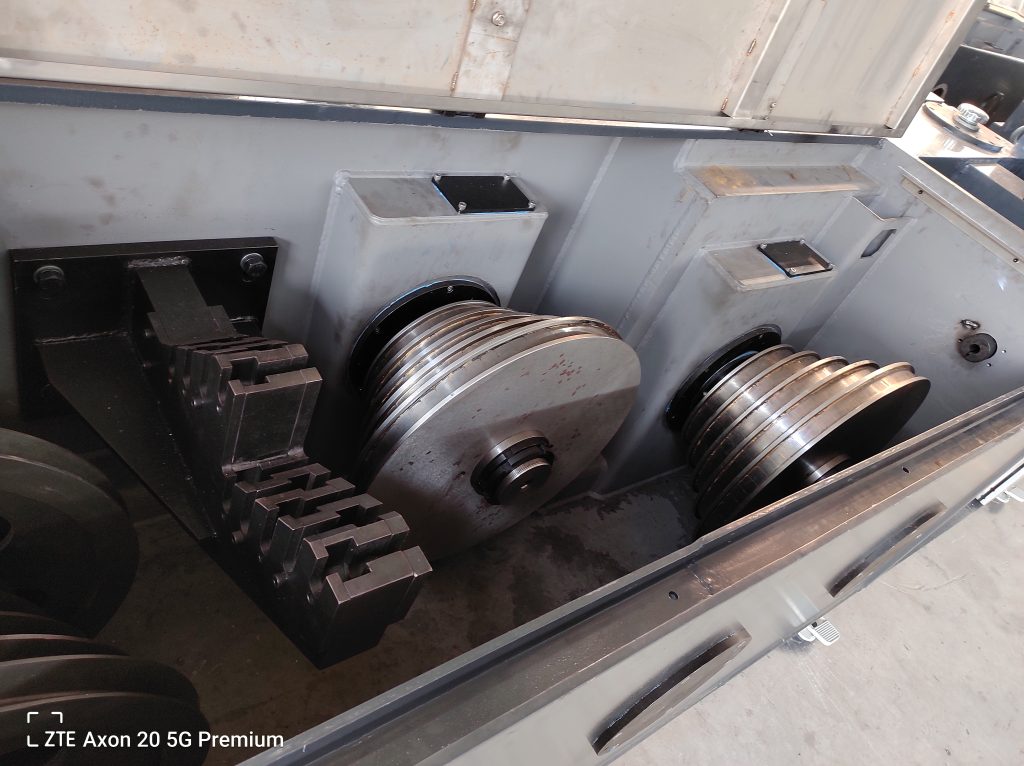

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wires, including aluminium wire. One of the methods used in wire drawing is the wet wire drawing process, which involves the use of a lubricant or coolant to reduce friction and heat during the drawing process. In this article, we will discuss the benefits of using a Wet Wire Drawing Machine for aluminium wire.

One of the main advantages of using a wet wire drawing machine for aluminium wire is the reduction in friction. Friction can cause excessive heat to build up during the drawing process, which can lead to the wire breaking or becoming damaged. By using a lubricant or coolant, the friction between the wire and the dies is reduced, allowing for a smoother and more efficient drawing process. This ultimately results in a higher quality finished product.

In addition to reducing friction, a wet wire drawing machine also helps to improve the surface finish of the wire. The lubricant or coolant acts as a barrier between the wire and the dies, preventing scratches or other imperfections from forming on the surface of the wire. This results in a smoother and more uniform finish, which is important for applications where the appearance of the wire is critical.

Another benefit of using a wet wire drawing machine for aluminium wire is the reduction in die wear. The lubricant or coolant helps to protect the dies from excessive wear and tear, extending their lifespan and reducing the need for frequent replacements. This not only helps to lower maintenance costs but also ensures consistent quality in the finished product.

Furthermore, a wet wire drawing machine can help to improve the overall efficiency of the drawing process. By reducing friction and heat, the machine can operate at higher speeds without compromising the quality of the wire. This results in increased productivity and lower production costs, making it a cost-effective solution for manufacturers.

Additionally, using a wet wire drawing machine for aluminium wire can also help to reduce the risk of defects in the finished product. The lubricant or coolant helps to prevent the formation of cracks or other imperfections in the wire, resulting in a higher quality and more reliable product. This is particularly important for applications where the wire will be subjected to high stress or pressure.

Overall, the benefits of using a wet wire drawing machine for aluminium wire are clear. From reducing friction and improving surface finish to extending die lifespan and increasing efficiency, this method offers numerous advantages for manufacturers. By investing in a wet wire drawing machine, manufacturers can ensure that they are producing high-quality aluminium wire that meets the needs of their customers.

Maintenance Tips for Wet Wire Drawing Machines for Aluminium Wire

Wet wire drawing machines are essential equipment in the production of aluminium wire. These machines are used to reduce the diameter of the wire by pulling it through a series of dies. The process involves lubricating the wire with a coolant to reduce friction and heat generation. Proper maintenance of wet wire drawing machines is crucial to ensure smooth operation and prolong the lifespan of the equipment.

One of the key maintenance tasks for wet wire drawing machines is regular cleaning. Over time, coolant, metal shavings, and other debris can build up on the machine’s components, leading to decreased efficiency and potential damage. It is important to clean the machine regularly to remove any buildup and ensure that it operates smoothly.

In addition to cleaning, it is important to inspect the machine for any signs of wear or damage. Check the dies, rollers, and other components for signs of wear, such as cracks or dents. Replace any damaged parts immediately to prevent further damage to the machine and ensure consistent wire quality.

Another important maintenance task for wet wire drawing machines is lubrication. Proper lubrication is essential to reduce friction and heat generation during the wire drawing process. Make sure to use the correct type of coolant and apply it regularly to ensure smooth operation of the machine.

Regularly inspect the coolant system to ensure that it is functioning properly. Check for leaks, clogs, or other issues that may affect the performance of the machine. Clean or replace filters as needed to maintain the quality of the coolant and prevent contamination of the wire.

It is also important to monitor the tension and speed of the wire during the drawing process. Improper tension or speed can lead to wire breakage or other issues. Make sure to adjust the tension and speed settings as needed to ensure smooth operation and consistent wire quality.

Regularly calibrate the machine to ensure accurate wire diameter and quality. Use a micrometer or other measuring device to check the diameter of the wire at regular intervals. Make any necessary adjustments to the machine to maintain the desired wire diameter and quality.

Finally, it is important to train operators on proper machine operation and maintenance procedures. Ensure that operators are familiar with the machine’s components, functions, and maintenance requirements. Provide training on how to clean, lubricate, and inspect the machine to ensure proper operation and prevent damage.

In conclusion, proper maintenance of wet wire drawing machines is essential to ensure smooth operation and prolong the lifespan of the equipment. Regular cleaning, inspection, lubrication, and calibration are key maintenance tasks that should be performed regularly. By following these maintenance tips, you can ensure that your wet wire drawing machine for aluminium wire operates efficiently and produces high-quality wire.

How to Choose the Right Wet Wire Drawing Machine for Aluminium Wire Production

When it comes to producing high-quality aluminium wire, choosing the right wet wire drawing machine is crucial. Wet wire drawing machines are specifically designed to draw wire through a series of dies while using a lubricant or coolant to reduce friction and heat during the process. This results in a smoother finish and improved mechanical properties of the wire.

There are several factors to consider when selecting a wet wire drawing machine for aluminium wire production. One of the most important considerations is the size and type of wire you will be producing. Different machines are designed to handle different wire diameters and materials, so it is essential to choose a machine that is suitable for your specific requirements.

Another key factor to consider is the speed and efficiency of the machine. The production capacity of the machine should match your production needs to ensure that you can meet demand without any delays. Additionally, the machine should be easy to operate and maintain to minimize downtime and maximize productivity.

It is also important to consider the quality and reliability of the machine. Look for a reputable manufacturer with a proven track record of producing high-quality machines that are built to last. A reliable machine will help you avoid costly repairs and replacements in the future.

When choosing a wet wire drawing machine for aluminium wire production, it is essential to consider the overall cost of the machine. While it may be tempting to opt for a cheaper machine, it is important to remember that quality comes at a price. Investing in a high-quality machine may cost more upfront, but it will pay off in the long run with improved efficiency and reduced maintenance costs.

In addition to the machine itself, it is also important to consider the availability of spare parts and technical support. Choose a manufacturer that offers a comprehensive warranty and after-sales service to ensure that you can quickly resolve any issues that may arise.

Overall, selecting the right wet wire drawing machine for aluminium wire production requires careful consideration of several factors, including the size and type of wire, speed and efficiency, quality and reliability, cost, and after-sales support. By taking the time to research and compare different machines, you can make an informed decision that will benefit your production process in the long run.