Table of Contents

Advanteges of Using a Wet Wire Drawing Machine in the Manufacturing Industry

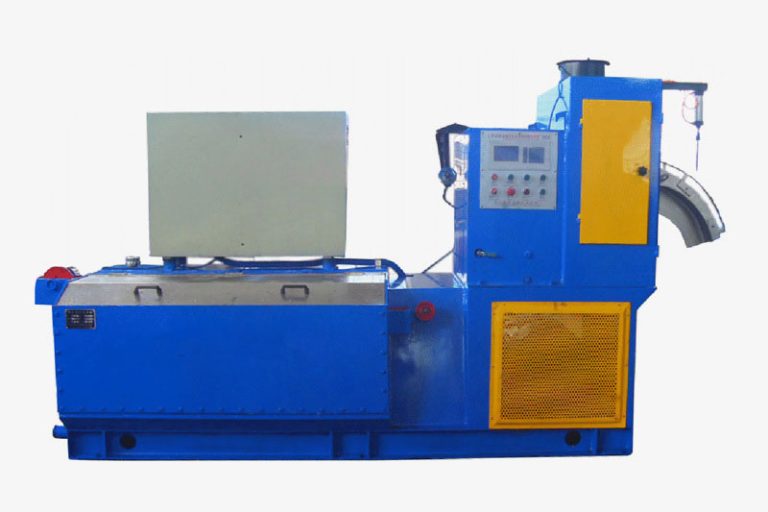

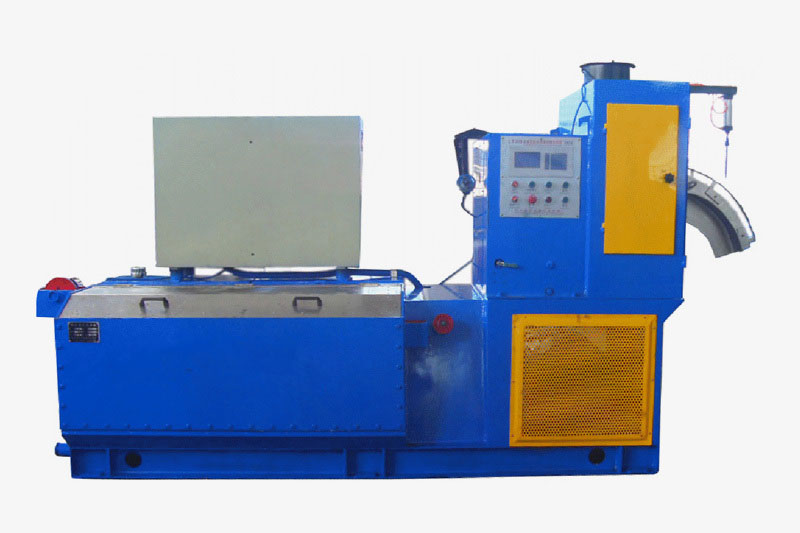

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One of the key tools used in wire drawing is the wire drawing machine, which comes in different types depending on the specific requirements of the wire being produced. One such type is the wet wire drawing machine, which offers several benefits that make it a popular choice in the manufacturing industry.

One of the main advantages of using a wet wire drawing machine is its ability to reduce friction during the drawing process. In a wet wire drawing machine, the wire is drawn through a lubricant, usually a water-based solution, which helps to reduce the heat generated during the drawing process. This not only helps to protect the wire from damage but also ensures a smoother and more efficient drawing process. The reduced friction also means that less force is required to draw the wire, which can lead to energy savings and increased productivity.

Another benefit of using a wet wire drawing machine is its ability to improve the surface finish of the wire. The lubricant used in the machine helps to remove any impurities or contaminants from the surface of the wire, resulting in a cleaner and smoother finish. This is particularly important for wires that are used in applications where surface quality is critical, such as in the production of electrical wiring or automotive components. By using a wet wire drawing machine, manufacturers can ensure that their wires meet the highest quality standards and are free from defects that could affect their performance.

In addition to improving the surface finish of the wire, a wet wire drawing machine can also help to extend the life of the drawing dies. The lubricant used in the machine helps to reduce wear and tear on the dies, which can prolong their lifespan and reduce the need for frequent replacements. This can result in cost savings for manufacturers, as they will not have to invest as much in maintaining and replacing their drawing dies. Additionally, the reduced wear on the dies can also help to improve the overall efficiency of the drawing process, as the dies will be able to maintain their shape and performance for longer periods of time.

Overall, the use of a wet wire drawing machine offers several benefits for manufacturers in the manufacturing industry. From reducing friction and improving surface finish to extending the life of drawing dies, this type of machine can help to improve the quality and efficiency of the wire drawing process. By investing in a wet wire drawing machine, manufacturers can ensure that they are able to produce high-quality wires that meet the demands of their customers and the industry as a whole.

Maintenance Tips for Ensuring Optimal Performance of a Wet Wire Drawing Machine

A wet wire drawing machine is a crucial piece of equipment in the wire manufacturing industry. It is used to reduce the diameter of wire by pulling it through a series of dies, which results in a smoother surface finish and improved mechanical properties. To ensure optimal performance and longevity of a wet wire drawing machine, regular maintenance is essential.

One of the most important maintenance tasks for a wet wire drawing machine is keeping the coolant system clean and well-maintained. The coolant helps to reduce friction and heat during the drawing process, which in turn helps to prolong the life of the dies and improve the quality of the finished wire. Regularly check the coolant levels and replace or top up as needed. It is also important to clean the coolant tank and filters regularly to prevent buildup of debris and contaminants that can clog the system.

In addition to maintaining the coolant system, it is important to regularly inspect and replace the dies on a wet wire drawing machine. Dies are subject to wear and tear over time, and using worn-out dies can result in poor quality wire and increased downtime for the machine. Inspect the dies regularly for signs of wear, such as chipping or cracking, and replace them as needed. It is also important to properly lubricate the dies to reduce friction and prevent premature wear.

Another important maintenance task for a wet wire drawing machine is to regularly inspect and adjust the tension on the wire. Proper tension is crucial for achieving the desired reduction in wire diameter and preventing breakage during the drawing process. Check the tension on the wire regularly and make adjustments as needed to ensure smooth operation of the machine.

Regularly inspecting and maintaining the drive system of a wet wire drawing machine is also essential for optimal performance. The drive system is responsible for pulling the wire through the dies, and any issues with the drive system can result in poor quality wire and increased downtime. Inspect the drive system regularly for signs of wear and tear, such as loose belts or worn pulleys, and replace or repair as needed. It is also important to properly lubricate the drive system to reduce friction and prevent premature wear.

In conclusion, regular maintenance is essential for ensuring optimal performance and longevity of a wet wire drawing machine. By keeping the coolant system clean and well-maintained, inspecting and replacing dies as needed, adjusting wire tension, and maintaining the drive system, you can help to prolong the life of your machine and improve the quality of the finished wire. Remember to follow the manufacturer’s guidelines for maintenance and consult with a professional if you are unsure about any aspect of maintaining your wet wire drawing machine. With proper care and maintenance, your wet wire drawing machine can continue to produce high-quality wire for years to come.