Table of Contents

Understanding of Using a Wet Drawing Machines for Textile Production

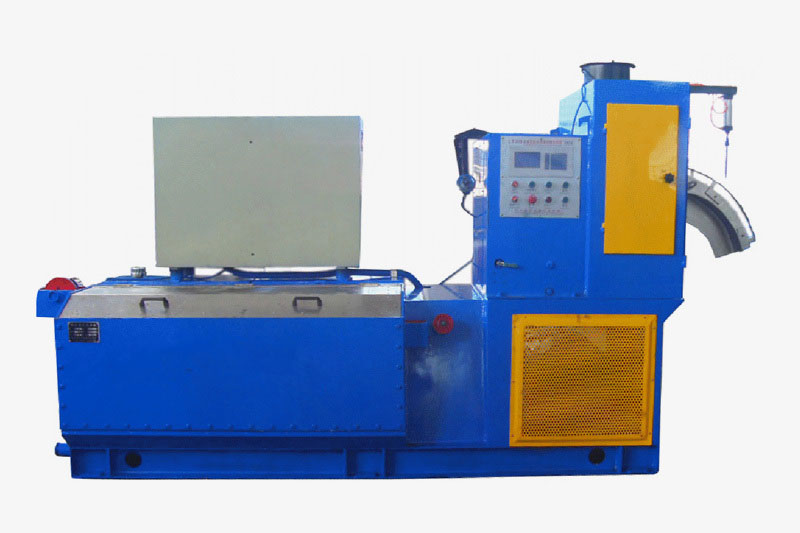

A Wet Wire Drawing Machine is a crucial piece of equipment in the textile production process. This machine is used to draw out fibers and create yarns that are strong, smooth, and consistent in size. There are several benefits to using a wet drawing machine in textile production.

One of the main advantages of using a wet drawing machine is the ability to produce high-quality yarns. The wet drawing process helps to align the fibers in the yarn, resulting in a smoother and more uniform product. This can lead to a higher quality finished textile that is more durable and has a better appearance.

In addition to improving the quality of the yarn, a wet drawing machine can also increase the efficiency of the production process. By drawing out the fibers in a controlled and consistent manner, this machine can help to reduce waste and improve overall productivity. This can result in cost savings for textile manufacturers and help them to meet production deadlines more effectively.

Another benefit of using a wet drawing machine is the ability to customize the yarns to meet specific requirements. By adjusting the speed and tension of the machine, manufacturers can create yarns with different properties, such as strength, elasticity, and softness. This flexibility allows textile producers to tailor their products to meet the needs of their customers and create unique and innovative textiles.

Furthermore, a wet drawing machine can help to improve the overall sustainability of the textile production process. By drawing out the fibers in a controlled and efficient manner, this machine can help to reduce the amount of energy and resources needed to produce yarns. This can lead to a more environmentally friendly production process and help textile manufacturers to reduce their carbon footprint.

Overall, the benefits of using a wet drawing machine in textile production are clear. From improving the quality of the yarn to increasing efficiency and customization options, this machine plays a crucial role in the manufacturing process. By investing in a wet drawing machine, textile producers can enhance the quality of their products, increase productivity, and reduce their environmental impact.

In conclusion, a Slip Wire Drawing Machine is an essential piece of equipment for textile production. Its ability to improve the quality of yarns, increase efficiency, customize products, and enhance sustainability make it a valuable asset for manufacturers. By utilizing a wet drawing machine, textile producers can create high-quality textiles that meet the needs of their customers and contribute to a more sustainable industry.

How to Maintain and Clean a Wet Drawing Machine for Optimal Performance

A wet drawing machine is a crucial piece of equipment in the manufacturing industry, used to produce high-quality wire and cable products. To ensure optimal performance and longevity of the machine, regular maintenance and cleaning are essential. In this article, we will discuss the steps involved in maintaining and cleaning a wet drawing machine.

First and foremost, it is important to establish a regular maintenance schedule for the wet drawing machine. This schedule should include daily, weekly, and monthly tasks to keep the machine running smoothly. Daily maintenance tasks may include checking for any leaks or unusual noises, inspecting the lubrication system, and cleaning any debris or dirt from the machine. Weekly tasks may involve checking the tension of the wire, inspecting the cooling system, and lubricating any moving parts. Monthly tasks may include inspecting the electrical components, checking the alignment of the machine, and replacing any worn-out parts.

When it comes to cleaning the wet drawing machine, there are several important steps to follow. The first step is to power off the machine and disconnect it from any power source. This is crucial to ensure the safety of the operator during the cleaning process. Next, remove any wire or cable from the machine and clean the drawing dies with a wire brush to remove any built-up residue. It is important to be gentle when cleaning the drawing dies to avoid damaging them.

After cleaning the drawing dies, it is important to clean the cooling system of the wet drawing machine. This system is responsible for keeping the machine at the optimal temperature during operation. To clean the cooling system, remove any debris or dirt from the cooling fins and check for any leaks in the system. It is also important to check the coolant levels and top up if necessary.

In addition to cleaning the drawing dies and cooling system, it is important to inspect and clean the lubrication system of the wet drawing machine. The lubrication system is responsible for ensuring that all moving parts of the machine operate smoothly. To clean the lubrication system, remove any old lubricant and debris from the system and replace it with fresh lubricant. It is important to use the correct type of lubricant for the machine to ensure optimal performance.

Once the drawing dies, cooling system, and lubrication system have been cleaned and inspected, it is important to reassemble the wet drawing machine and perform a test run. During the test run, check for any unusual noises or vibrations and ensure that the machine is operating smoothly. If any issues are detected during the test run, it is important to address them immediately to prevent further damage to the machine.

In conclusion, maintaining and cleaning a wet drawing machine is essential to ensure optimal performance and longevity. By following a regular maintenance schedule and cleaning the drawing dies, cooling system, and lubrication system, you can keep your wet drawing machine running smoothly and producing high-quality wire and cable products. Remember to always follow safety guidelines and manufacturer recommendations when performing maintenance and cleaning tasks on the machine.

Creative Techniques for Using a Wet Drawing Machine in Art and Design

A wet drawing machine is a versatile tool that can be used in a variety of creative ways in art and design. This machine consists of a flat surface that can be wetted with water or another liquid, allowing for unique drawing techniques to be employed. By using a wet drawing machine, artists and designers can create stunning works of art that incorporate elements of fluidity and unpredictability.

One of the key benefits of using a wet drawing machine is the ability to create dynamic and expressive lines. When a drawing surface is wet, the liquid allows for the ink or paint to flow freely, resulting in fluid and organic shapes. This can add a sense of movement and energy to a piece, making it more visually engaging. By varying the amount of liquid on the surface, artists can control the intensity and direction of the lines, allowing for a wide range of effects to be achieved.

In addition to creating expressive lines, a wet drawing machine can also be used to blend colors in a unique and interesting way. By applying different colors of ink or paint to the wet surface, artists can create beautiful gradients and transitions between hues. The liquid on the surface helps to blend the colors together, creating a soft and seamless effect. This technique can be particularly effective for creating atmospheric and ethereal compositions, as the colors blend together in a dreamy and surreal manner.

Another creative technique that can be achieved with a wet drawing machine is the creation of textures and patterns. By manipulating the liquid on the surface, artists can create a variety of textures, from smooth and glossy to rough and gritty. This can add depth and dimension to a piece, making it more tactile and visually interesting. By experimenting with different tools and techniques, artists can create a wide range of textures and patterns, allowing for endless possibilities in their work.

One of the most exciting aspects of using a wet drawing machine is the element of unpredictability. Because the liquid on the surface is constantly moving and shifting, artists have less control over the final outcome of their work. This can lead to unexpected and surprising results, adding an element of spontaneity and creativity to the artistic process. By embracing this unpredictability, artists can push the boundaries of their creativity and explore new possibilities in their work.

Overall, a wet drawing machine is a valuable tool for artists and designers looking to explore new techniques and push the boundaries of their creativity. By using this machine, artists can create dynamic and expressive lines, blend colors in unique ways, create textures and patterns, and embrace the element of unpredictability in their work. Whether used for sketching, painting, or mixed media projects, a wet drawing machine offers endless possibilities for creative expression.