Table of Contents

How to Choose the Right Welding Electrodes Straightening and Cutting Machine for Your Needs

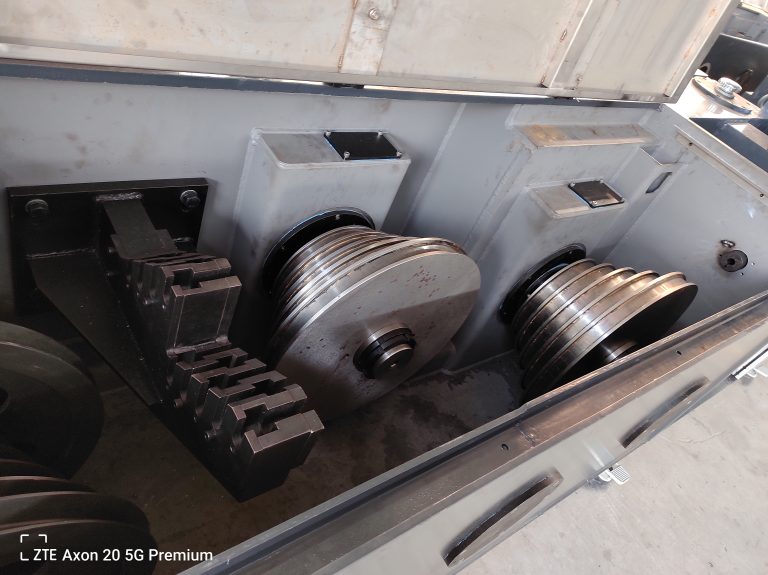

Straightening And Cutting Machine For Welding Electrodes are essential tools in the welding industry. These machines are used to straighten and cut welding electrodes to the desired length, ensuring precision and efficiency in the welding process. Choosing the right welding electrodes straightening and cutting machine for your needs is crucial to achieving high-quality welds and maximizing productivity.

When selecting a welding electrodes straightening and cutting machine, there are several factors to consider. The first factor to consider is the type of welding electrodes you will be working with. Different types of welding electrodes require different machines with specific features to ensure proper straightening and cutting. It is important to choose a machine that is compatible with the type and size of welding electrodes you will be using.

Another important factor to consider is the production capacity of the machine. The production capacity of a welding electrodes straightening and cutting machine refers to the number of electrodes it can straighten and cut in a given time period. If you have a high-volume welding operation, you will need a machine with a high production capacity to keep up with demand. On the other hand, if you have a smaller welding operation, a machine with a lower production capacity may be sufficient.

In addition to production capacity, it is important to consider the accuracy and precision of the machine. A high-quality welding electrodes straightening and cutting machine should be able to straighten and cut electrodes with precision, ensuring that each electrode is the correct length and free of defects. Look for machines with features such as adjustable cutting lengths and automatic feeding systems to ensure accuracy and consistency in the welding process.

Durability and reliability are also important factors to consider when choosing a welding electrodes straightening and cutting machine. A machine that is built to last and can withstand the rigors of daily use will provide long-term value and reliability. Look for machines made from high-quality materials and with a solid construction to ensure durability and longevity.

Ease of use and maintenance are also important considerations when choosing a welding electrodes Wire Straightening and Cutting Machines. A machine that is easy to operate and maintain will save time and effort in the welding process. Look for machines with user-friendly controls and easy access to components for maintenance and repairs.

Finally, consider the cost of the welding electrodes straightening and cutting machine. While it is important to invest in a high-quality machine that meets your needs, it is also important to consider your budget. Compare prices and features of different machines to find the best value for your money.

In conclusion, choosing the right welding electrodes straightening and cutting machine is essential for achieving high-quality welds and maximizing productivity in the welding process. Consider factors such as the type of welding electrodes, production capacity, accuracy and precision, durability and reliability, ease of use and maintenance, and cost when selecting a machine. By carefully evaluating these factors, you can choose a machine that meets your needs and provides long-term value and performance in your welding operation.

Benefits of Using Welding Electrodes Straightening and Cutting Machines

Welding electrodes are a crucial component in the welding process, as they provide the necessary heat and filler material to create strong and durable welds. However, welding electrodes can often become bent or misshapen during storage or transportation, which can lead to difficulties in the welding process. This is where welding electrodes straightening and cutting machines come into play.

These machines are specifically designed to straighten and cut welding electrodes quickly and efficiently, ensuring that they are in optimal condition for use in welding applications. By using a welding electrodes Automatic Wire Straightening and Cutting Machine, welders can save time and effort, as well as improve the quality of their welds.

One of the key benefits of using welding electrodes straightening and cutting machines is the ability to ensure that the electrodes are straight and uniform in shape. This is essential for achieving consistent and high-quality welds, as any deviations in the shape of the electrode can lead to uneven heat distribution and weak welds. By straightening and cutting the electrodes with a machine, welders can be confident that they are using the best possible materials for their welding projects.

In addition to improving the quality of welds, welding electrodes straightening and cutting machines also help to increase efficiency in the welding process. By automating the process of straightening and cutting electrodes, these machines can save valuable time that would otherwise be spent manually straightening and cutting each electrode. This allows welders to focus on the actual welding process, rather than wasting time on tedious and repetitive tasks.

Furthermore, welding electrodes straightening and cutting machines can also help to reduce waste in the welding process. When electrodes become bent or misshapen, they are often discarded as they are no longer suitable for use. By using a machine to straighten and cut the electrodes, welders can salvage these materials and ensure that they are not wasted. This can lead to cost savings for welders, as well as a more sustainable approach to welding.

Another benefit of using welding electrodes straightening and cutting machines is the improved safety that they provide. When electrodes are bent or misshapen, they can be difficult to handle and can pose a safety risk to welders. By using a machine to straighten and cut the electrodes, welders can avoid the risk of injury from handling sharp or misshapen materials. This can help to create a safer working environment for welders, reducing the likelihood of accidents and injuries in the welding process.

Overall, welding electrodes straightening and cutting machines offer a range of benefits to welders, including improved quality, increased efficiency, reduced waste, and enhanced safety. By investing in these machines, welders can ensure that they are using the best possible materials for their welding projects, while also saving time and effort in the process. Whether working on small-scale projects or large industrial applications, welding electrodes straightening and cutting machines are a valuable tool for any welder looking to improve their welding process.