Table of Contents

Advantages of Using Welding Electrodes Cutting Machines

Welding electrodes wire straightening and cutting machine are essential tools in the welding industry, providing a precise and efficient way to cut through various materials. These machines offer a wide range of advantages that make them a popular choice among welders and fabricators.

One of the main advantages of using welding electrodes cutting machines is their versatility. These machines can cut through a variety of materials, including steel, aluminum, and stainless steel, making them suitable for a wide range of welding projects. Whether you are working on a small DIY project or a large industrial job, welding electrodes cutting machines can handle the task with ease.

In addition to their versatility, welding electrodes cutting machines are also known for their precision. These machines are equipped with advanced technology that allows for accurate and clean cuts, ensuring that your welding project is completed to the highest standards. This precision is essential in welding, as even the smallest mistake can compromise the integrity of the weld.

Another advantage of using welding electrodes cutting machines is their efficiency. These machines are designed to cut through materials quickly and efficiently, saving you time and labor costs. With a welding electrodes cutting machine, you can complete your welding projects in a fraction of the time it would take using traditional cutting methods.

Furthermore, Automatic Wire Straightening and Cutting Machine are easy to use, making them accessible to welders of all skill levels. These machines are equipped with user-friendly controls and interfaces, allowing even beginners to operate them with ease. This accessibility makes welding electrodes cutting machines a valuable tool for both professional welders and hobbyists alike.

Additionally, welding electrodes cutting machines are durable and long-lasting, providing you with a reliable tool that will withstand the rigors of daily use. These machines are built to withstand the demands of the welding industry, ensuring that they will continue to perform at their best for years to come. This durability makes welding electrodes cutting machines a smart investment for any welding shop or fabrication facility.

In conclusion, welding electrodes cutting machines offer a wide range of advantages that make them an essential tool for welders and fabricators. From their versatility and precision to their efficiency and ease of use, these machines provide a reliable and efficient way to cut through materials for welding projects of all sizes. If you are looking to improve the quality and efficiency of your welding work, consider investing in a welding electrodes cutting machine today.

How to Choose the Right Welding Electrodes Cutting Machine for Your Project

Welding electrodes cutting machines are essential tools for any welding project. These machines are used to cut and shape metal pieces with precision and accuracy. Choosing the right welding electrodes cutting machine for your project is crucial to ensure that you achieve the desired results. There are several factors to consider when selecting a welding electrodes cutting machine, including the type of metal you will be working with, the thickness of the metal, and the size of the project.

One of the first things to consider when choosing a Straightening And Cutting Machine For Welding Electrodes cutting machine is the type of metal you will be working with. Different metals require different cutting techniques and equipment. For example, cutting through steel requires a different machine than cutting through aluminum. It is important to choose a machine that is specifically designed for the type of metal you will be working with to ensure that you achieve clean and precise cuts.

Another important factor to consider when choosing a welding electrodes cutting machine is the thickness of the metal. Thicker metals require more power and a higher cutting capacity than thinner metals. It is important to choose a machine that can handle the thickness of the metal you will be working with to ensure that you achieve the desired results. Additionally, some machines are designed for cutting through thick metals, while others are better suited for cutting through thin metals. It is important to choose a machine that is appropriate for the thickness of the metal you will be working with to ensure that you achieve clean and precise cuts.

The size of the project is also an important factor to consider when choosing a welding electrodes cutting machine. Larger projects require a machine with a higher cutting capacity and more power than smaller projects. It is important to choose a machine that is appropriate for the size of the project you will be working on to ensure that you achieve the desired results. Additionally, some machines are designed for cutting through large pieces of metal, while others are better suited for cutting through smaller pieces. It is important to choose a machine that is appropriate for the size of the project you will be working on to ensure that you achieve clean and precise cuts.

In conclusion, choosing the right welding electrodes cutting machine for your project is crucial to ensure that you achieve the desired results. Consider factors such as the type of metal you will be working with, the thickness of the metal, and the size of the project when selecting a machine. By choosing a machine that is appropriate for your specific needs, you can ensure that you achieve clean and precise cuts on your welding project.

Maintenance Tips for Welding Electrodes Cutting Machines

Welding electrodes cutting machines are essential tools in the welding industry, used to cut and shape metal with precision and efficiency. To ensure that these machines operate at their best, regular maintenance is crucial. By following a few simple tips, you can keep your welding electrodes cutting machine in top condition and extend its lifespan.

One of the most important maintenance tasks for welding electrodes cutting machines is keeping them clean. Metal shavings, dust, and debris can build up on the machine over time, causing it to operate less efficiently. Regularly cleaning the machine with a brush or compressed air can help prevent this buildup and keep the machine running smoothly.

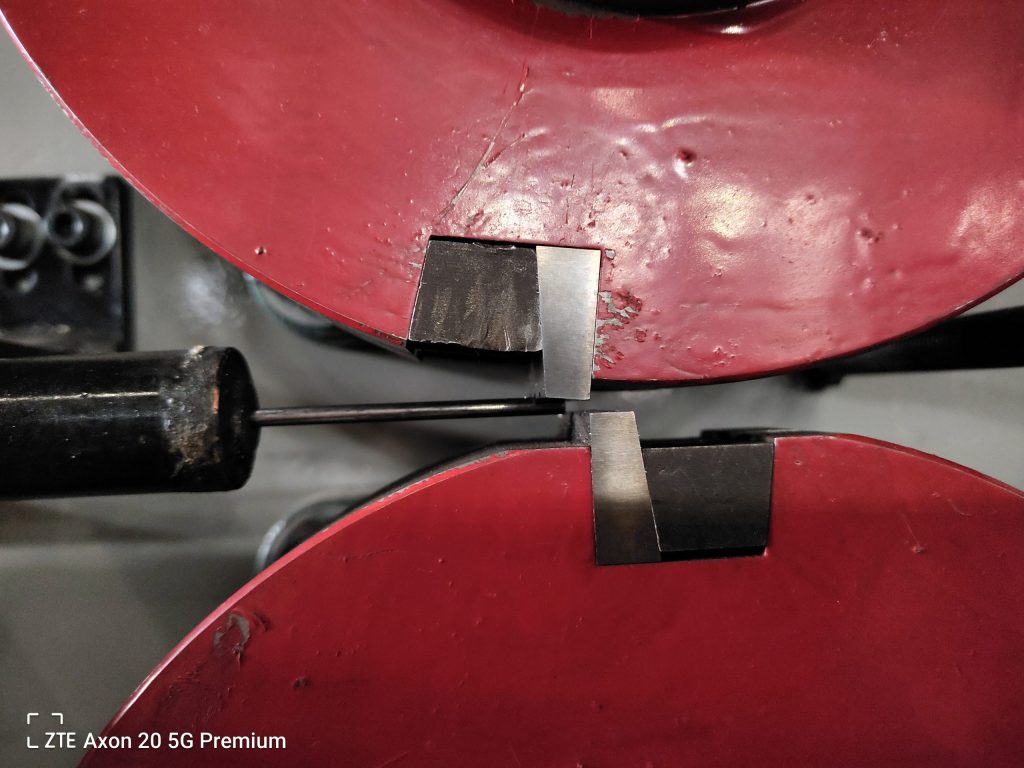

In addition to keeping the machine clean, it is also important to regularly inspect and replace the cutting electrodes. Over time, these electrodes can become worn down or damaged, leading to poor cutting performance. By inspecting the electrodes regularly and replacing them when necessary, you can ensure that your machine continues to cut with precision.

Another important maintenance task for welding electrodes cutting machines is checking and adjusting the machine’s settings. Over time, the settings on the machine can become misaligned or out of calibration, leading to poor cutting performance. By regularly checking and adjusting the settings, you can ensure that the machine is cutting accurately and efficiently.

It is also important to regularly lubricate the moving parts of the welding electrodes cutting machine. Proper lubrication can help prevent wear and tear on the machine’s components and ensure that it operates smoothly. Be sure to use the correct type of lubricant for your machine and follow the manufacturer’s recommendations for lubrication intervals.

In addition to these regular maintenance tasks, it is also important to address any issues or problems with the machine as soon as they arise. Ignoring problems can lead to more serious issues down the line and may result in costly repairs or downtime. If you notice any unusual noises, vibrations, or other signs of trouble with your welding electrodes cutting machine, be sure to address them promptly.

By following these maintenance tips, you can keep your welding electrodes cutting machine in top condition and ensure that it continues to operate at its best. Regular cleaning, inspection, and lubrication can help prevent issues and extend the lifespan of the machine. By addressing any problems promptly and following the manufacturer’s recommendations for maintenance, you can keep your welding electrodes cutting machine running smoothly for years to come.