Table of Contents

How to Choose the Right Water-Tank Wire Drawing Machine Manufacturer for Your Business

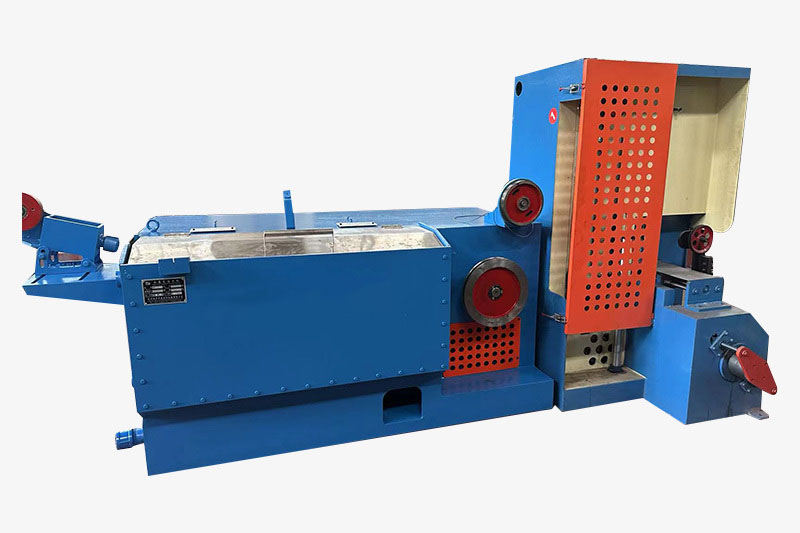

When it comes to choosing the right water-tank wire drawing machine manufacturer for your business, there are several factors to consider. From the quality of the machines to the reputation of the manufacturer, making the right choice can have a significant impact on the success of your operations. In this article, we will discuss some key considerations to keep in mind when selecting a water-tank wire drawing machine manufacturer.

First and foremost, it is essential to consider the quality of the machines produced by the manufacturer. Water-tank wire drawing machines are complex pieces of equipment that require precision engineering to ensure optimal performance. Look for a manufacturer that has a reputation for producing high-quality machines that are built to last. This will help you avoid costly repairs and downtime in the future.

In addition to quality, it is also important to consider the range of machines offered by the manufacturer. Different businesses have different needs when it comes to wire drawing machines, so it is essential to find a manufacturer that offers a variety of options to choose from. Whether you need a small, compact machine for a small-scale operation or a larger, more powerful machine for a larger operation, make sure the manufacturer can provide the right solution for your business.

Another important factor to consider when choosing a Wet Wire Drawing Machine manufacturer is their reputation in the industry. Look for manufacturers that have a track record of delivering on their promises and providing excellent customer service. Reading reviews and testimonials from other businesses that have worked with the manufacturer can give you valuable insight into their reputation and reliability.

Cost is also a crucial consideration when selecting a water-tank wire drawing machine manufacturer. While it is essential to find a manufacturer that offers competitive pricing, it is equally important not to sacrifice quality for a lower price. Look for a manufacturer that offers a good balance between affordability and quality to ensure you are getting the best value for your money.

When choosing a water-tank wire drawing machine manufacturer, it is also important to consider their level of customer support. A manufacturer that provides excellent customer service can help you troubleshoot any issues that may arise with your machines and ensure that your operations run smoothly. Look for a manufacturer that offers comprehensive support services, such as training programs and maintenance plans, to help you get the most out of your investment.

In conclusion, choosing the right water-tank wire drawing machine manufacturer for your business is a crucial decision that can have a significant impact on your operations. By considering factors such as quality, range of machines, reputation, cost, and customer support, you can make an informed decision that will benefit your business in the long run. Take the time to research and compare different manufacturers to find the best fit for your specific needs and requirements.

Benefits of Using Water-Tank Wire Drawing Machines in Manufacturing Processes

Water-tank wire drawing machines are an essential tool in the manufacturing industry, particularly in the production of wires and cables. These machines offer a wide range of benefits that can significantly improve the efficiency and quality of the manufacturing process.

One of the key advantages of using Slip Wire Drawing Machine is their ability to produce high-quality wires with precise dimensions. The water cooling system in these machines helps to control the temperature of the wire during the drawing process, ensuring that the final product meets the required specifications. This level of precision is crucial in industries where the quality of the wire is paramount, such as in the production of electrical cables or automotive components.

In addition to producing high-quality wires, water-tank wire drawing machines also offer increased productivity. The water cooling system allows for faster drawing speeds, which means that more wire can be produced in a shorter amount of time. This can help manufacturers meet tight deadlines and increase their overall output without sacrificing quality.

Furthermore, water-tank wire drawing machines are known for their durability and reliability. These machines are built to withstand the rigors of continuous use in a manufacturing environment, making them a long-term investment for any company. With proper maintenance and care, these machines can last for many years, providing consistent performance and reliable results.

Another benefit of using water-tank wire drawing machines is their versatility. These machines can be used to draw a wide range of wire sizes and materials, making them suitable for a variety of manufacturing applications. Whether you need to produce thin copper wires for electronics or thick steel wires for construction, a water-tank wire drawing machine can handle the job with ease.

Additionally, water-tank wire drawing machines are relatively easy to operate and maintain. With proper training, operators can quickly learn how to set up and run these machines, minimizing downtime and maximizing productivity. Routine maintenance tasks, such as cleaning and lubricating the machine, can help prolong its lifespan and ensure consistent performance.

Overall, the benefits of using water-tank wire drawing machines in manufacturing processes are clear. From producing high-quality wires to increasing productivity and versatility, these machines offer a range of advantages that can help companies improve their operations and stay competitive in today’s market. By investing in a water-tank wire drawing machine, manufacturers can streamline their production processes, reduce costs, and deliver superior products to their customers.