Benefits of Using a Wet Wire Drawing Machine

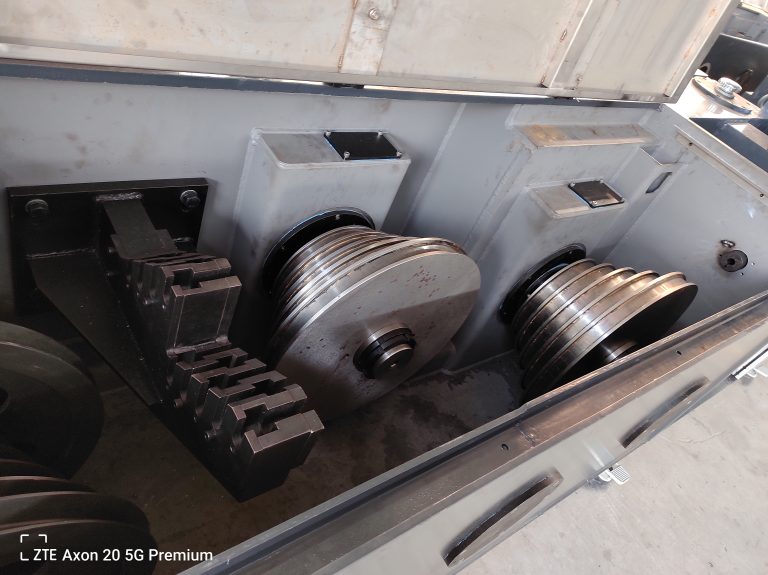

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One of the key components in the wire drawing process is the wire drawing machine, which helps to ensure a smooth and efficient operation.

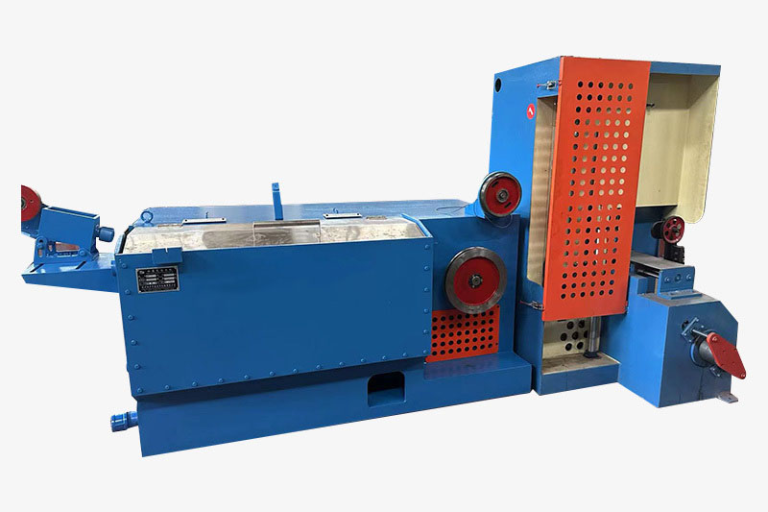

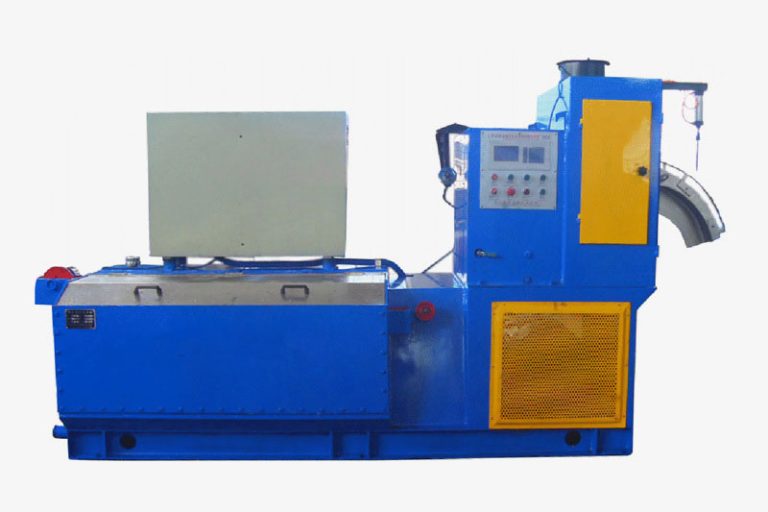

One type of wire drawing machine that is commonly used in the industry is the water-tank wire drawing machine. This machine is equipped with a water tank that helps to cool the wire as it is being drawn through the dies. The cooling process is important because it helps to prevent the wire from overheating and becoming brittle, which can lead to breakage and other issues.

There are several benefits to using a water-tank wire drawing machine. One of the main advantages is that it helps to improve the quality of the wire being produced. By cooling the wire as it is being drawn, the machine helps to ensure that the wire maintains its strength and flexibility, which is essential for its intended use. This can result in a higher quality product that is less likely to break or fail under stress.

Another benefit of using a Slip Wire Drawing Machine is that it can help to increase the productivity of the manufacturing process. By cooling the wire more efficiently, the machine can operate at higher speeds without compromising the quality of the wire. This means that more wire can be produced in a shorter amount of time, which can help to reduce production costs and improve overall efficiency.

In addition to improving quality and productivity, a water-tank wire drawing machine can also help to reduce maintenance and repair costs. Because the cooling process helps to prevent the wire from overheating, there is less wear and tear on the dies and other components of the machine. This can help to extend the lifespan of the machine and reduce the need for costly repairs and replacements.

Furthermore, using a water-tank wire drawing machine can also help to improve safety in the workplace. By keeping the wire cool during the drawing process, the machine helps to reduce the risk of accidents and injuries that can occur when working with hot or brittle wire. This can create a safer working environment for employees and help to prevent costly downtime due to accidents.

Overall, the benefits of using a water-tank wire drawing machine are clear. From improving quality and productivity to reducing maintenance costs and enhancing safety, this type of machine can offer numerous advantages for manufacturers in the wire drawing industry. By investing in a water-tank wire drawing machine, companies can improve their operations and produce higher quality wire products that meet the needs of their customers.