Table of Contents

Advantages of Using Vertical Wire Drawing Machines in Industrial Applications

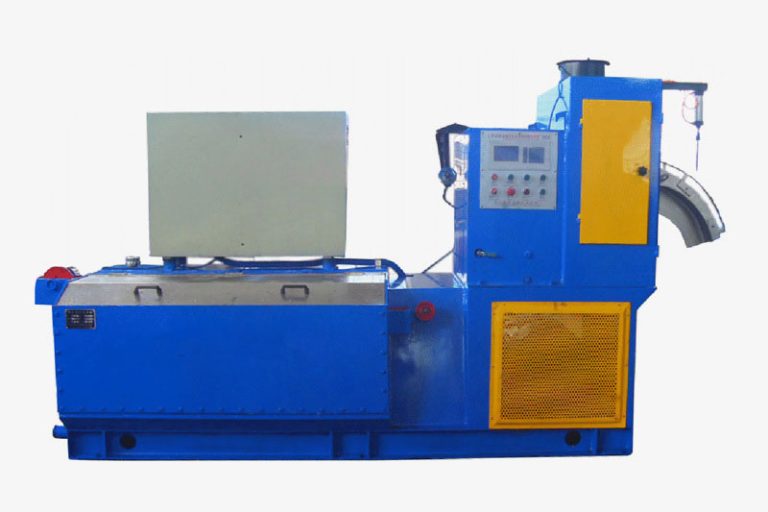

Vertical winding machines have become an essential tool in various industrial applications due to their efficiency and versatility. These machines are designed to wind materials such as wire, cable, rope, and tubing onto spools or reels in a vertical orientation. In this article, we will explore the advantages of using vertical winding machines in industrial settings.

One of the primary advantages of vertical winding machines is their space-saving design. Unlike horizontal winding machines that require a large footprint, vertical winding machines can be installed in tight spaces, making them ideal for facilities with limited floor space. This compact design allows companies to maximize their production area and increase efficiency.

In addition to their space-saving design, Vertical Type Wire Drawing Machine offer increased productivity. These machines are equipped with advanced automation features that allow for continuous operation without the need for constant monitoring. This automation not only speeds up the winding process but also ensures consistent and precise winding results, reducing the risk of errors and rework.

Furthermore, vertical winding machines are highly customizable to meet the specific needs of different industries. Whether you are winding thin wires or thick cables, these machines can be tailored to accommodate various materials and spool sizes. This flexibility makes vertical winding machines a versatile solution for a wide range of applications, from telecommunications to construction.

Another advantage of using vertical winding machines is their ergonomic design. These machines are built with operator comfort and safety in mind, featuring easy-to-use controls and ergonomic workstations. This ergonomic design reduces operator fatigue and minimizes the risk of injuries, resulting in a safer and more efficient work environment.

Moreover, vertical winding machines are known for their high winding accuracy. These machines are equipped with precision winding mechanisms that ensure uniform tension and layering of the material onto the spool. This level of accuracy is crucial for industries that require consistent and high-quality winding results, such as the aerospace and automotive sectors.

Additionally, vertical winding machines are cost-effective solutions for companies looking to streamline their production processes. These machines are designed to operate efficiently with minimal maintenance, reducing downtime and repair costs. Furthermore, the automation features of vertical winding machines help companies save on labor costs by eliminating the need for manual winding.

In conclusion, vertical winding machines offer numerous advantages for industrial applications, including space-saving design, increased productivity, customization options, ergonomic features, high winding accuracy, and cost-effectiveness. These machines have become indispensable tools for companies looking to optimize their production processes and improve overall efficiency. Whether you are in the telecommunications, construction, aerospace, or automotive industry, vertical winding machines can help you achieve your winding goals with precision and reliability.

How to Choose the Right Vertical Winding Machine for Your Manufacturing Needs

Vertical type drawing machines are essential tools in the manufacturing industry, used for winding various materials onto spools or bobbins. These machines come in a variety of sizes and configurations, each designed to meet specific manufacturing needs. Choosing the right vertical winding machine for your production requirements is crucial to ensure efficiency and quality in your manufacturing process.

When selecting a vertical winding machine, there are several factors to consider. The first consideration is the type of material you will be winding. Different materials, such as wire, yarn, or tape, require different winding techniques and machine specifications. It is important to choose a machine that is specifically designed to handle the material you will be working with to ensure optimal performance.

Another important factor to consider is the size and weight of the spools or bobbins you will be winding. Vertical winding machines come in various capacities, with some able to handle larger and heavier spools than others. It is essential to choose a machine that can accommodate the size and weight of the spools you will be using to prevent damage to the machine and ensure smooth operation.

Additionally, consider the speed and precision requirements of your manufacturing process. Some vertical winding machines are designed for high-speed winding, while others are more suited for precision winding with tight tolerances. Depending on your production needs, choose a machine that can meet the speed and precision requirements of your manufacturing process to ensure consistent quality in your finished products.

It is also important to consider the space available in your manufacturing facility. Vertical winding machines come in various sizes, from compact tabletop models to larger floor-standing units. Ensure that you have enough space to accommodate the machine you choose and that it can be easily integrated into your existing production line for seamless operation.

When selecting a vertical winding machine, it is also important to consider the ease of use and maintenance. Look for machines that are user-friendly and easy to operate, with intuitive controls and features that simplify the winding process. Additionally, choose a machine that is easy to maintain, with accessible components and a reliable support system to ensure minimal downtime and maximum productivity.

Finally, consider the reputation and reliability of the manufacturer when choosing a vertical winding machine. Look for manufacturers with a proven track record of producing high-quality machines and providing excellent customer support. Reading reviews and testimonials from other customers can help you gauge the reliability and performance of a particular machine before making a purchase.

In conclusion, choosing the right vertical winding machine for your manufacturing needs is essential to ensure efficiency, quality, and productivity in your production process. Consider factors such as the type of material, size and weight of spools, speed and precision requirements, available space, ease of use and maintenance, and the reputation of the manufacturer when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific requirements, you can streamline your manufacturing process and achieve optimal results in your finished products.