Table of Contents

İşletmeniz için Doğru Hassas Tel Katmanı Sarma Makinesi Nasıl Seçilir

Günümüzün hızlı ilerleyen imalat endüstrisinde, kaynak teli hassas katman sarma makinesi, çeşitli elektrikli bileşenlerin üretiminde çok önemli bir rol oynamaktadır. Bu makineler, teli bir makaraya veya bobine hassasiyetle ve doğrulukla sarmak ve nihai ürünün gerekli özellikleri karşılamasını sağlamak üzere tasarlanmıştır. Verimli üretim ve yüksek kaliteli çıktı sağlamak için işletmeniz için doğru hassas tel katmanı sarma makinesini seçmek çok önemlidir.

Hassas bir tel katmanı sarma makinesi seçerken, dikkate alınması gereken birkaç faktör vardır. Dikkat edilmesi gereken ilk husus, sarılacak telin türüdür. Farklı makineler, farklı tip ve boyutlardaki telleri işleyecek şekilde tasarlanmıştır, bu nedenle kullanacağınız tel ile uyumlu bir makine seçmeniz önemlidir. Ayrıca makinenin hızını ve kapasitesini de göz önünde bulundurun. Bazı makineler yüksek hızlarda tel sarma kapasitesine sahipken diğerleri daha küçük üretim çalışmaları için daha uygundur.

Hassas tel sarma makinesi seçerken göz önünde bulundurulması gereken bir diğer önemli faktör otomasyon düzeyidir. Bazı makineler, hassas sarma modellerine ve gerginlik kontrolüne olanak tanıyan programlanabilir kontrollerle tamamen otomatiktir. Bu makineler yüksek hacimli üretim için idealdir ve verimliliğin ve tutarlılığın artırılmasına yardımcı olabilir. Öte yandan, manuel makineler daha fazla operatör müdahalesi gerektirir ancak daha küçük üretim süreçleri için daha uygun maliyetli olabilir.

Makinenin genel kalitesini ve güvenilirliğini de dikkate almak önemlidir. Uzun süre dayanacak şekilde üretilmiş ve saygın bir üretici tarafından desteklenen bir makine arayın. Güvenilir bir makine, üretiminizin sorunsuz ve verimli bir şekilde ilerlemesini sağlayarak arıza süresini ve bakım maliyetlerini en aza indirmeye yardımcı olacaktır.

Hassas bir tel katmanı sarma makinesi seçerken, makinenin sunduğu kişiselleştirme düzeyini ve esnekliği dikkate almak da önemlidir. Bazı makineler özel uygulamalar için tasarlanmıştır ve farklı sarım gereksinimlerine kolaylıkla uyarlanamayabilir. Çeşitli sarım seçenekleri sunan ve özel ihtiyaçlarınızı karşılayacak şekilde kolayca ayarlanabilen bir makine arayın.

Makinenin teknik özelliklerinin dikkate alınmasının yanı sıra, üretici tarafından sağlanan destek ve hizmet düzeyinin de dikkate alınması önemlidir. Makinenizin en yüksek performansta çalışmasını sağlamak için eğitim, teknik destek ve bakım hizmetleri sunan bir şirket arayın.

Sonuç olarak, işletmeniz için doğru hassas tel katmanı sarma makinesini seçmek, verimli üretim ve yüksek kalite sağlamak için çok önemlidir. çıktı. Kararınızı verirken kablo türü, hız ve kapasite, otomasyon düzeyi, kalite ve güvenilirlik, özelleştirme ve esneklik ile destek ve hizmet düzeyi gibi faktörleri göz önünde bulundurun. Bu faktörleri dikkatlice değerlendirip özel ihtiyaçlarınızı karşılayan bir makine seçerek üretiminizin sorunsuz ve verimli bir şekilde ilerlemesini sağlayabilirsiniz.

İmalat Süreçlerinde Hassas Tel Katman Sarma Makinesi Kullanmanın Faydaları

Üretim dünyasında hassasiyet çok önemlidir. En yüksek kalitede son ürünü sağlamak için her bileşen, her süreç, her ayrıntı dikkatle kontrol edilmelidir. Üretimin hassasiyet gerektiren önemli yönlerinden biri tel katmanlarının sarılmasıdır. Transformatörler, motorlar veya başka herhangi bir elektrikli bileşen için olsun, optimum performansın sağlanması için tel katmanlarının sarılması son derece hassas bir şekilde yapılmalıdır. Hassas tel katmanı sarma makinesinin devreye girdiği yer burasıdır.

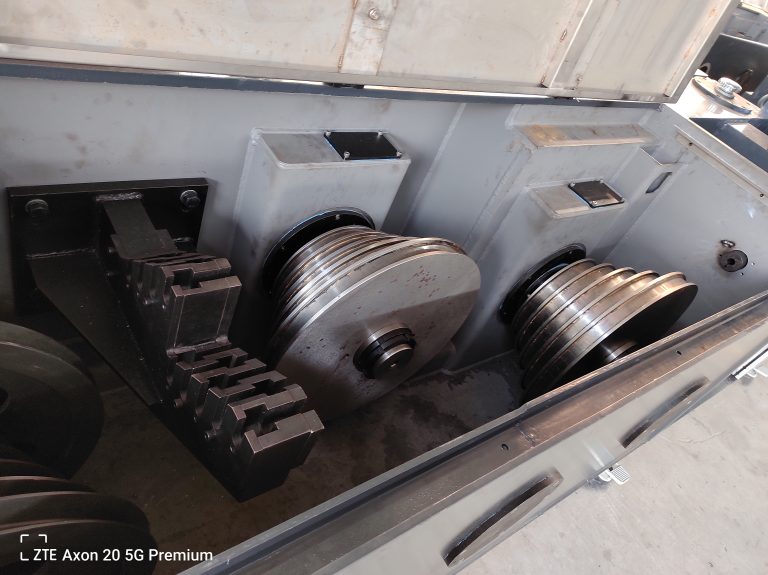

Düz tel veya kablo hassas katman sarma makinesi, tel katmanlarını inanılmaz doğruluk ve tutarlılıkla sarmak için tasarlanmış özel bir ekipman parçasıdır. Bu makineler, makaraya veya bobine sarılan telin gerginliğini, hızını ve yerleşimini hassas bir şekilde kontrol etmelerini sağlayan ileri teknolojiyle donatılmıştır. Bu seviyedeki hassasiyet, tel katmanlarının nihai ürünün bütünlüğünü tehlikeye atabilecek herhangi bir boşluk veya örtüşme olmaksızın eşit ve sıkı bir şekilde sarılmasını sağlamak için gereklidir.

Hassas tel katmanı sarma makinesi kullanmanın en önemli faydalarından biri, yüksek kaliteli tel katmanlarını tutarlı bir şekilde üretebilme yeteneğidir. İnsan hatasını ve değişkenliği ortadan kaldıran bu makineler, her bir tel katmanının uygulama için gerekli olan spesifikasyonlara göre sarılmasını sağlayabilir. Bu düzeyde tutarlılık, katı kalite standartlarını karşılamak ve son ürünün güvenilirliğini ve performansını sağlamak için gereklidir.

Hassas tel katmanı sarma makinesi kullanmanın bir başka yararı da üretim sürecinde üretkenliği ve verimliliği artırma yeteneğidir. Bu makineler, tel katmanlarını manuel yöntemlere göre çok daha hızlı sarma kapasitesine sahip olup, üreticilerin daha kısa sürede daha fazla bileşen üretmesine olanak tanır. Bu, teslim sürelerinin azaltılmasına, çıktının artırılmasına ve sonuçta üretim sürecinin genel verimliliğinin iyileştirilmesine yardımcı olabilir.

Kaliteyi ve verimliliği artırmanın yanı sıra, hassas tel katmanı sarma makineleri aynı zamanda atıkların azaltılmasına ve malzeme maliyetlerinin en aza indirilmesine de yardımcı olabilir. Bu makineler, tel katmanlarını daha yüksek doğrulukla sararak her bir bileşen için doğru miktarda telin kullanılmasını sağlayarak fazla malzeme ihtiyacını ortadan kaldırır ve hurdayı azaltır. Bu, üreticiler için önemli maliyet tasarruflarının yanı sıra daha sürdürülebilir ve çevre dostu bir üretim süreciyle sonuçlanabilir.

Genel olarak, üretim süreçlerinde hassas bir tel katmanı sarma makinesi kullanmanın faydaları açıktır. Bu makineler, kalite ve tutarlılığın iyileştirilmesinden üretkenliğin ve verimliliğin arttırılmasına kadar, üreticilerin yüksek kaliteli bileşenleri daha etkili ve verimli bir şekilde üretmelerine yardımcı olabilecek çok çeşitli avantajlar sunar. Üreticiler, hassas bir tel katmanı sarma makinesine yatırım yaparak üretim süreçlerini bir sonraki seviyeye taşıyabilir ve günümüzün rekabetçi pazarında daha büyük başarı elde edebilir.