Table of Contents

pag-unawa sa Wire Drawing Machine sa Industrial Applications

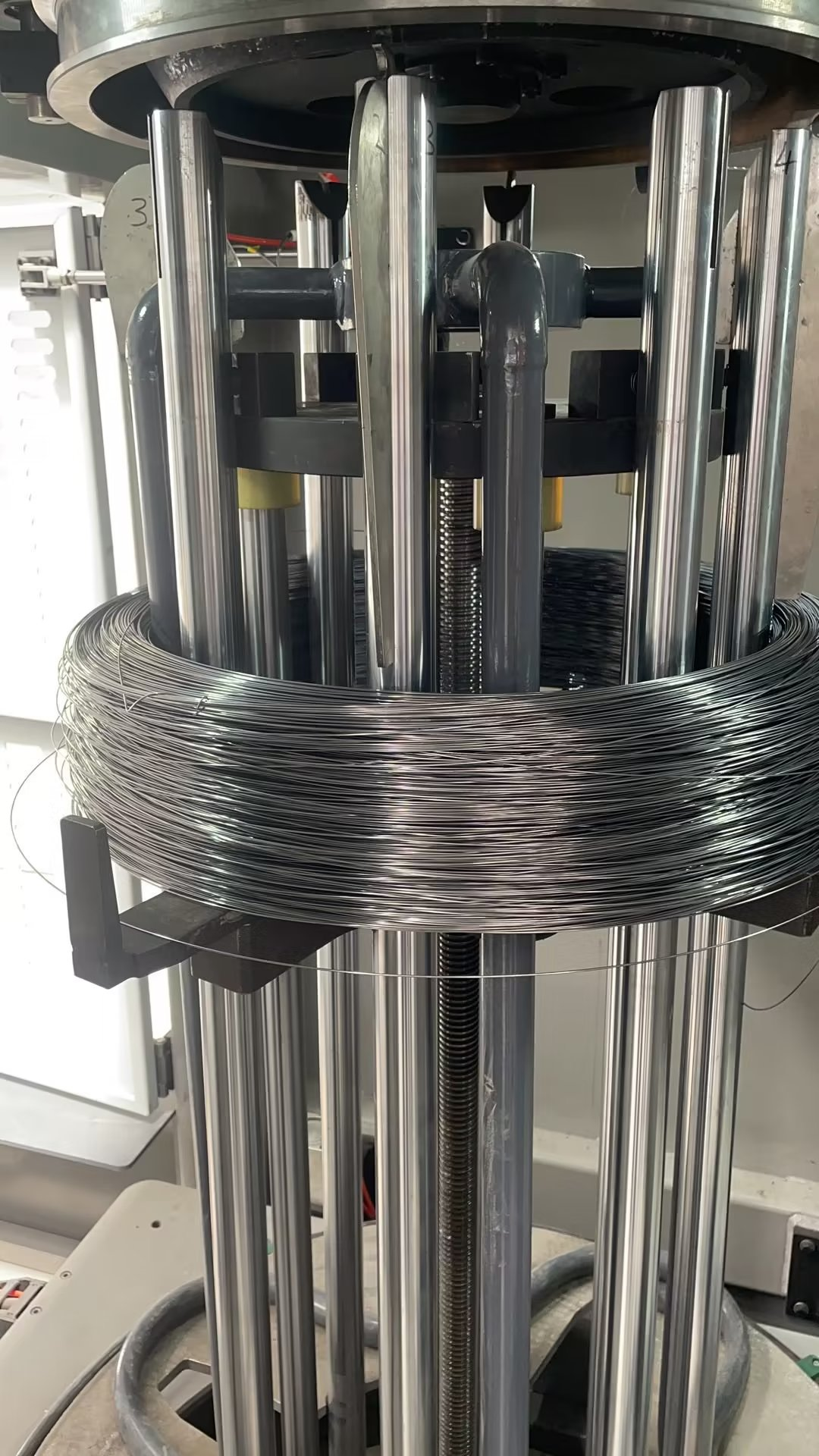

Ang mga wire drawing machine ay mahahalagang kasangkapan sa sektor ng industriya para sa paggawa ng mga wire na may iba’t ibang diameter at haba. Ang mga makinang ito ay ginagamit sa malawak na hanay ng mga industriya, kabilang ang automotive, construction, electronics, at telekomunikasyon. Ang proseso ng pagguhit ng wire ay nagsasangkot ng paghila ng isang metal rod o wire sa pamamagitan ng isang serye ng mga dies upang mabawasan ang diameter nito at tumaas ang haba nito. Nagreresulta ito sa isang mas makinis, mas malakas, at mas pare-parehong wire na angkop para sa iba’t ibang mga application.

Isa sa mga pangunahing benepisyo ng paggamit ng Straight Line Wire Drawing Machine ay ang kakayahang gumawa ng mga wire na may tumpak na sukat. Ang mga makinang ito ay nilagyan ng maraming dies na maaaring iakma upang makamit ang ninanais na diameter at haba ng wire. Ang antas ng katumpakan na ito ay mahalaga sa mga industriya kung saan ang pagkakapare-pareho at katumpakan ay pinakamahalaga, tulad ng sa paggawa ng mga de-koryenteng cable o mga bahagi ng sasakyan.

Paano Pumili ng Tamang Wire Drawing Machine para sa Iyong Negosyo

Ang mga wire drawing machine ay mahalagang kagamitan para sa mga negosyong gumagana sa mga metal wire. Ang mga makinang ito ay ginagamit upang bawasan ang diameter ng isang wire sa pamamagitan ng paghila nito sa isang serye ng mga dies, na nagreresulta sa isang mas makinis at mas pare-parehong wire. Ang pagpili ng tamang wire drawing machine para sa iyong negosyo ay mahalaga upang matiyak ang kahusayan at kalidad sa iyong proseso ng produksyon.

Kapag pumipili ng wire drawing machine, may ilang salik na dapat isaalang-alang. Ang unang pagsasaalang-alang ay ang uri ng wire na iyong gagawin. Ang iba’t ibang wire drawing machine ay idinisenyo para sa mga partikular na uri ng wire, tulad ng bakal, tanso, o aluminyo. Mahalagang pumili ng makina na tugma sa materyal na iyong gagamitin upang matiyak ang pinakamainam na pagganap.

Wire drawing machines are essential equipment for businesses that work with metal wires. These machines are used to reduce the diameter of a wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. Choosing the right wire drawing machine for your business is crucial to ensure efficiency and quality in your production process.

When selecting a wire drawing machine, there are several factors to consider. The first consideration is the type of wire you will be working with. Different wire drawing machines are designed for specific types of wire, such as steel, copper, or aluminum. It is important to choose a machine that is compatible with the material you will be using to ensure optimal performance.

Another important factor to consider is the size and capacity of the wire drawing machine. The size of the machine should be appropriate for the volume of wire you will be processing. If you have a high production volume, you will need a machine with a larger capacity to handle the workload efficiently. On the other hand, if you have a smaller operation, a smaller machine may be sufficient.

The speed of the wire drawing machine is also an important consideration. The speed at which the wire is drawn through the dies will determine the final diameter of the wire. It is important to choose a machine with the appropriate speed for the type of wire you are working with and the desired diameter of the finished product.

In addition to these factors, it is important to consider the quality and reliability of the wire drawing machine. Look for a machine that is made from high-quality materials and is built to last. A reliable machine will help you avoid costly downtime and maintenance issues, ensuring smooth operation and consistent production.

When choosing a wire drawing machine, it is also important to consider the level of automation and control features. Some machines offer advanced automation features that can help improve efficiency and productivity. Look for a machine that offers easy-to-use controls and automation options that suit your production needs.

Finally, consider the cost of the wire drawing machine. While it is important to invest in a high-quality machine, it is also important to consider your budget and choose a machine that offers the best value for your money. Compare prices and features from different manufacturers to find a machine that meets your requirements and fits within your budget.

In conclusion, choosing the right wire drawing machine for your business is a crucial decision that can impact the efficiency and quality of your production process. Consider factors such as the type of wire, size and capacity, speed, quality and reliability, automation features, and cost when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your requirements, you can ensure smooth operation and consistent production in your business.