Straightening and Cutting Machine for Welding Electrodes

High Speed Wire Cutting Machine is the machine specially designed for making welding electrodes.

It is in the procedure of electrodes making of steel wire cutting and takes good effect if it works with high speed wire drawing machines.

Straightening and Cutting Machine for Welding Electrodes Max. speed is 1000 pieces/min with low noise, high efficiency, less spare parts. Wire collecting bucket is applied with signal sense to manage quantity of wire collecting automatically to reduce labor and working strength.

High Speed Wire Cutting Machine is the competitive replacement for normal wire cutting machine; the cutting length is 300mm, 350mm, 400mm, and 450mm.

High Speed Cutting Machine can reduce the noise from 80-90 dB to 10-20 dB than old type cutting machine.

Straightening And Cutting Machine For Welding Electrodes

High-speed cutting machine

WIRE STRAIGHTENING & CUTTING

| No. | Model | Technical data |

| 1 |

Cutting length |

350mm

300mm |

| 2 | Material | Low carbon steel wire |

| 3 | Cutting diameter | Φ3.2mm/Φ2.6mm/Φ2.0mm |

| 4 | Max. Cutting speed | 1200pcs/min |

| 5 | Length error range | ±1mm

The kerf of electrode core is very smooth without burr |

| 6 | Total power | 30.45kw |

| 7 | Auxiliary roll machine overall size | 1200*1100*1400 |

| Electrode conveyor and collection machine

overall size |

2500*800*1500 | |

| Collection case overall size | 900*550*900 | |

| 8 | Weight | 5.5 T |

HIGH-SPEED STRAIGHTENING & CUTTING,

The complete machine is composed of Auxiliary roll machine, main machine and Transmission and electrode core collect machine.

Note: If there is many different electrodes specifications you also you have to buy extra spare parts for it.

The extra device including

1, feeding rolls

2, Straightening device,

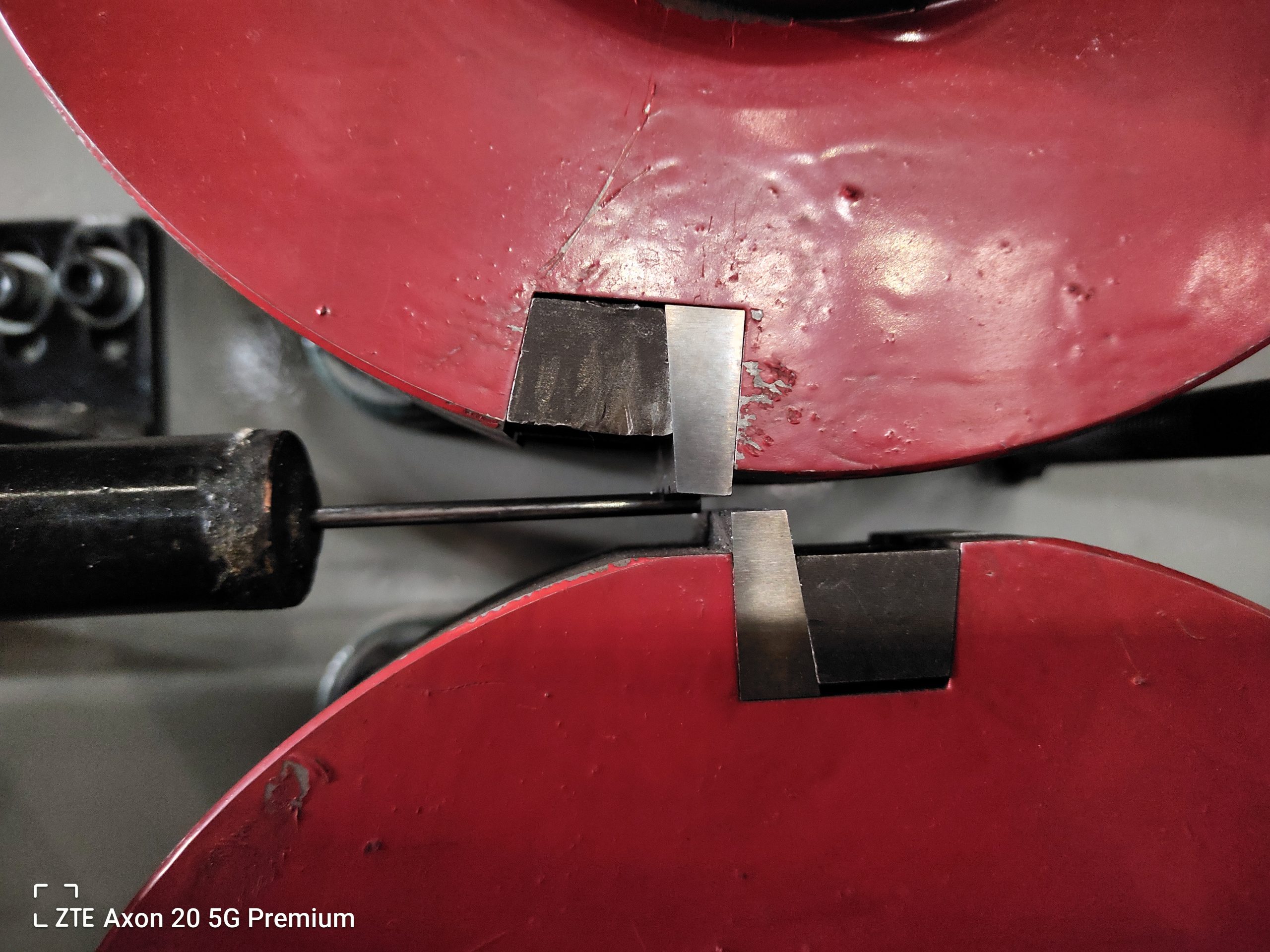

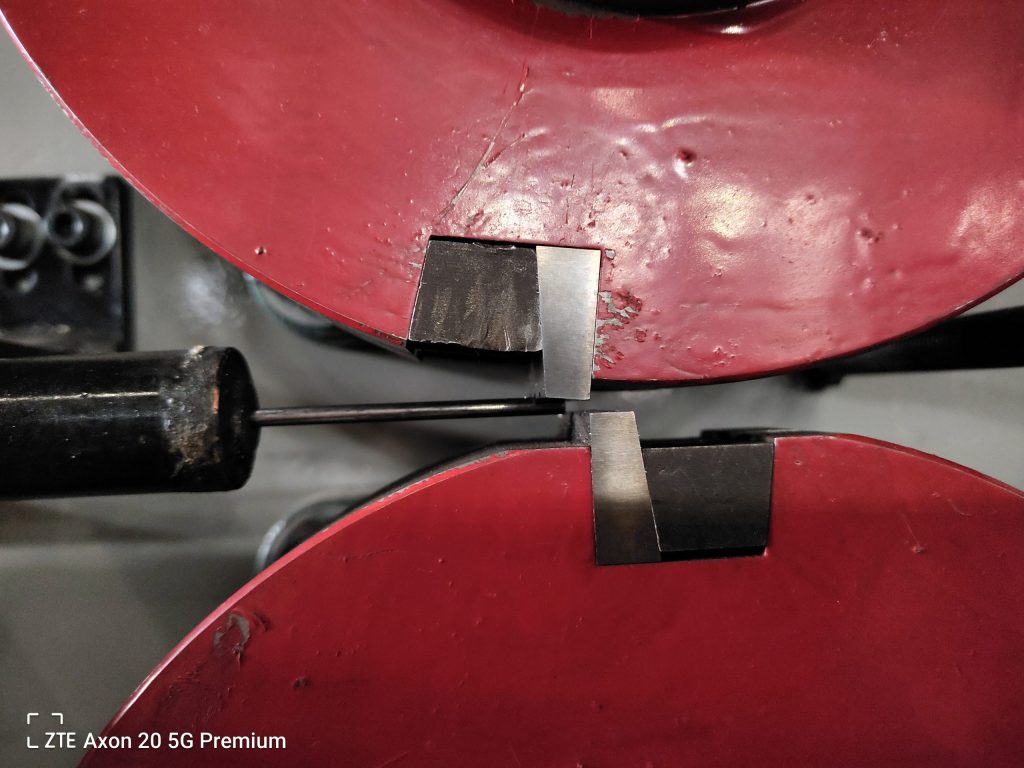

3, The Cutting device

4, Transmission belt.

The upon parts are standard parts and can replace very easy.