Mga Tip para sa Pagtitiyak ng Longevity ng Awtomatikong Straightening at Cutting Machine

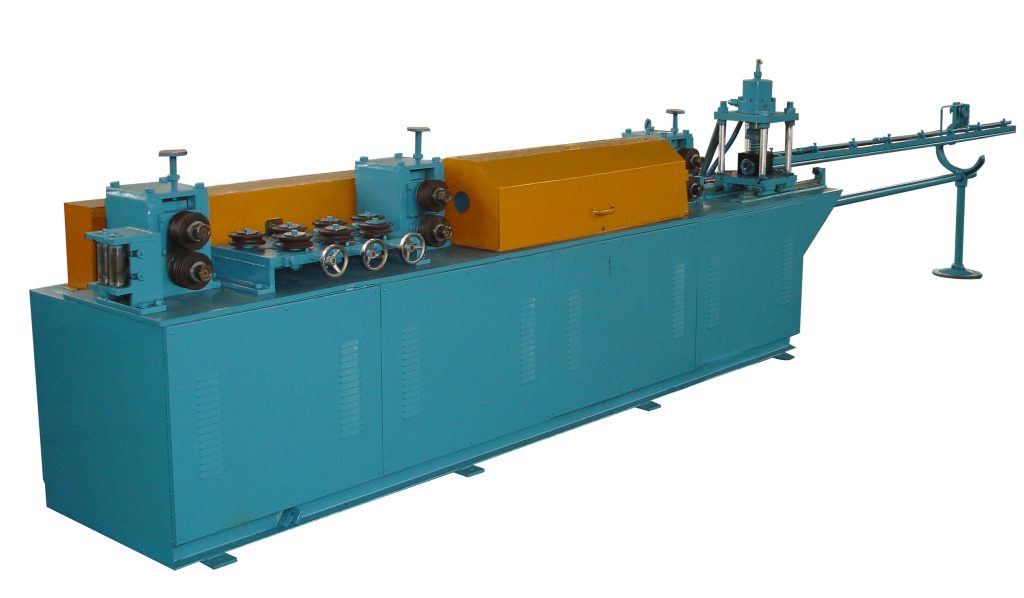

Ang Awtomatikong Wire Straightening at Cutting Machine ay mahahalagang tool sa iba’t ibang industriya, gaya ng construction, manufacturing, at automotive. Ang mga makinang ito ay idinisenyo upang mahusay na ituwid at gupitin ang mga metal rod, wire, at tubo sa tumpak na haba at sukat. Upang matiyak ang mahabang buhay at pinakamainam na pagganap ng iyong awtomatikong straightening at cutting machine, ang wastong pagpapanatili ay mahalaga.

Isa sa pinakamahalagang tip sa pagpapanatili para sa awtomatikong straightening at cutting machine ay ang regular na paglilinis. Maaaring maipon ang alikabok, debris, at metal shaving sa mga bahagi ng makina, na humahantong sa pagtaas ng pagkasira. Inirerekomenda na linisin ang makina pagkatapos ng bawat paggamit upang maiwasan ang buildup at matiyak ang maayos na operasyon. Gumamit ng malambot na brush o naka-compress na hangin upang alisin ang anumang dumi o mga labi mula sa mga ibabaw at bahagi ng makina.

Ang pag-inspeksyon sa makina para sa anumang mga palatandaan ng pagkasira o pagkasira ay mahalaga din para mapanatili ang mahabang buhay nito. Regular na suriin ang mga cutting blades, straightening roller, at iba pang kritikal na bahagi para sa anumang mga palatandaan ng pagkasira, tulad ng pagkapurol o pagpapapangit. Palitan kaagad ang anumang sira o nasirang bahagi upang maiwasan ang karagdagang pinsala sa Strightening And Cutting Machine Para sa Steel Bar at tiyakin ang tumpak na mga resulta ng pagputol at pagtutuwid.

Ang regular na pag-calibrate sa makina ay isa pang mahalagang tip sa pagpapanatili para sa mga awtomatikong straightening at cutting machine. Sa paglipas ng panahon, maaaring mag-drift ang mga setting ng makina, na makakaapekto sa katumpakan ng mga proseso ng pagputol at pagtutuwid. Inirerekomenda na i-calibrate ang makina nang pana-panahon upang matiyak ang tumpak at pare-parehong mga resulta. Sundin ang mga alituntunin ng manufacturer para sa mga pamamaraan ng pag-calibrate at iskedyul para mapanatili ang performance ng makina.

Ang wastong imbakan ng awtomatikong straightening at cutting machine ay mahalaga din para sa mahabang buhay nito. Kapag hindi ginagamit, itago ang makina sa isang malinis, tuyo, at maaliwalas na lugar upang maiwasan ang kalawang at kaagnasan. Takpan ang makina ng proteksiyon na tarp o sheet upang maprotektahan ito mula sa alikabok at mga labi. Bukod pa rito, isaalang-alang ang pamumuhunan sa isang takip ng makina o enclosure upang magbigay ng karagdagang proteksyon mula sa mga elemento ng kapaligiran.

Ang regular na pag-inspeksyon at pagpapanatili ng mga de-koryenteng bahagi ng awtomatikong Straightening And Cutting Machiner ay mahalaga para sa kaligtasan at mahabang buhay. Suriin ang mga kable ng kuryente, switch, at iba pang mga de-koryenteng koneksyon para sa anumang mga palatandaan ng pagkasira o pagkasira. Siguraduhin na ang makina ay wastong naka-ground at ang lahat ng mga de-koryenteng bahagi ay nasa mabuting kondisyon sa paggana. Kung may napansin kang anumang isyu, makipag-ugnayan sa isang kwalipikadong technician para sa pagkukumpuni o pagpapalit.

Sa pamamagitan ng pagsunod sa mga tip sa pagpapanatili na ito, masisiguro mo ang mahabang buhay at pinakamainam na pagganap ng iyong awtomatikong straightening at cutting machine. Ang regular na paglilinis, pagpapadulas, inspeksyon, pagkakalibrate, wastong pag-iimbak, at pagpapanatili ng kuryente ay mga pangunahing aspeto ng pagpapanatili ng makina sa pinakamataas na kondisyon. Tandaang sundin ang mga alituntunin at rekomendasyon ng manufacturer para sa mga pamamaraan ng pagpapanatili upang ma-maximize ang habang-buhay ng iyong awtomatikong straightening at cutting machine.