Table of Contents

Understand of Using a Straightening Wires Machine in Manufacturing Processes

In the world of manufacturing, precision and efficiency are key factors in ensuring the success of a business. One important aspect of manufacturing processes that often goes overlooked is the straightening of wires. Wires are used in a wide range of industries, from automotive to aerospace, and having straight wires is crucial for the quality and functionality of the final product. This is where a straightening wires machine comes into play.

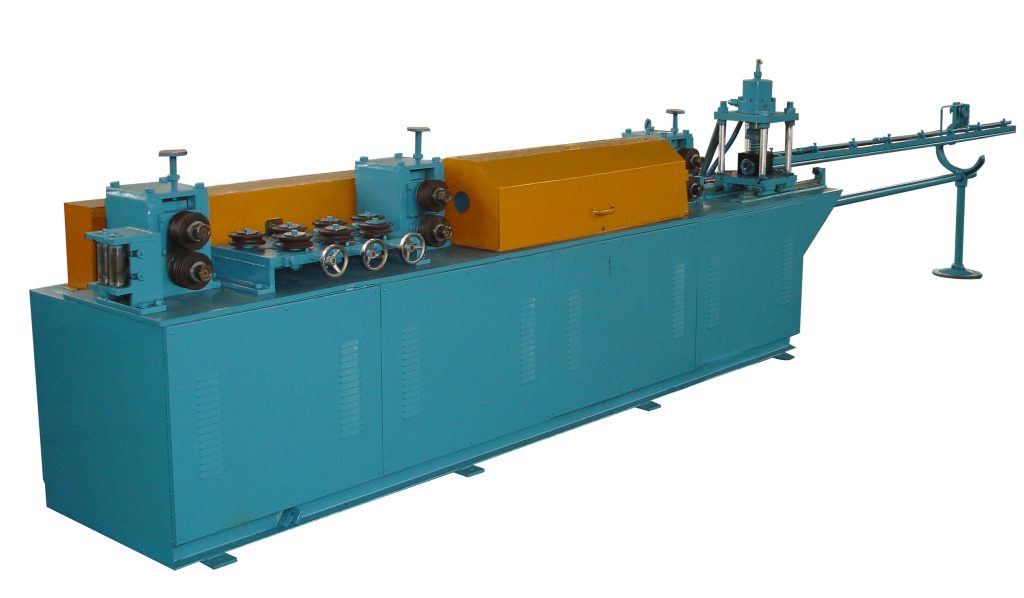

A Straightening And Cutting Machine For Steel Bar is a piece of equipment that is designed to straighten wires quickly and accurately. These machines are typically used in high-volume manufacturing settings where large quantities of wires need to be straightened on a regular basis. By using a straightening wires machine, manufacturers can ensure that their wires are straightened to the exact specifications required for their products.

One of the key benefits of using a straightening and cutting machine is the time savings it provides. Manual wire straightening can be a time-consuming and labor-intensive process, especially when dealing with large quantities of wires. By using a straightening wires machine, manufacturers can significantly reduce the amount of time it takes to straighten wires, allowing them to increase their production output and meet tight deadlines.

In addition to time savings, a straightening wires machine also offers improved accuracy and consistency. Manual wire straightening can be prone to human error, resulting in wires that are not perfectly straight. This can lead to issues with the final product, such as poor performance or premature failure. By using a straightening wires machine, manufacturers can ensure that their wires are straightened to the exact specifications required, resulting in a higher quality end product.

Another benefit of using a straightening wires machine is the reduction in waste. When wires are not straightened properly, they may need to be discarded, leading to unnecessary waste and increased production costs. By using a straightening wires machine, manufacturers can minimize waste by ensuring that all wires are straightened correctly the first time, reducing the need for rework and saving money in the long run.

Furthermore, a straightening wires machine can also improve worker safety. Manual wire straightening can be a hazardous task, especially when dealing with sharp or heavy wires. By using a straightening wires machine, manufacturers can reduce the risk of injury to their workers, creating a safer work environment and reducing the likelihood of workplace accidents.

Overall, the benefits of using a straightening wires machine in manufacturing processes are clear. From time savings and improved accuracy to reduced waste and increased worker safety, a straightening wires machine offers a wide range of advantages for manufacturers looking to streamline their production processes. By investing in a straightening wires machine, manufacturers can improve the quality and efficiency of their manufacturing operations, ultimately leading to greater success and profitability in the long run.

How to Choose the Right Straightening Wires Machine for Your Business

When it comes to manufacturing processes that involve wires, having a Straightening And Cutting Machine For Welding Electrodes wires machine is essential for ensuring the quality and precision of the final product. These machines are designed to straighten wires of various materials and diameters, making them a valuable asset for businesses in industries such as automotive, construction, and electronics.

Choosing the right straightening wires machine for your business can be a daunting task, as there are many factors to consider. From the type of wire you will be working with to the production volume and budget constraints, it is important to carefully evaluate your needs before making a decision.

One of the first things to consider when choosing a straightening wires machine is the type of wire you will be working with. Different machines are designed to handle different materials, such as steel, aluminum, copper, and more. Additionally, the diameter of the wire will also play a role in determining the type of machine that is best suited for your needs.

Another important factor to consider is the production volume of your business. If you have a high volume of wire straightening needs, you will want to invest in a machine that is capable of handling large quantities of wire efficiently. On the other hand, if your production volume is lower, a smaller machine may be more cost-effective.

Budget constraints are also an important consideration when choosing a straightening wires machine. These machines can vary greatly in price, depending on their capabilities and features. It is important to set a budget and stick to it, while also ensuring that you are getting a machine that meets your needs and will provide a good return on investment.

In addition to these factors, it is also important to consider the features and capabilities of the machine. Some machines come with additional features such as automatic feeding and cutting, digital controls, and adjustable straightening rollers. These features can help to improve efficiency and accuracy in the wire straightening process.

When evaluating different machines, it is also important to consider the reputation of the manufacturer. Look for a company that has a proven track record of producing high-quality machines that are reliable and durable. Reading reviews and testimonials from other customers can also help you make an informed decision.

Ultimately, choosing the right straightening wires machine for your business will depend on a variety of factors, including the type of wire you will be working with, production volume, budget constraints, and desired features. By carefully evaluating your needs and researching different machines, you can find a machine that will help improve the quality and efficiency of your wire straightening process.