Table of Contents

Understand The Maintenance Tips for Steel Bar Straightening and Cutting Machines

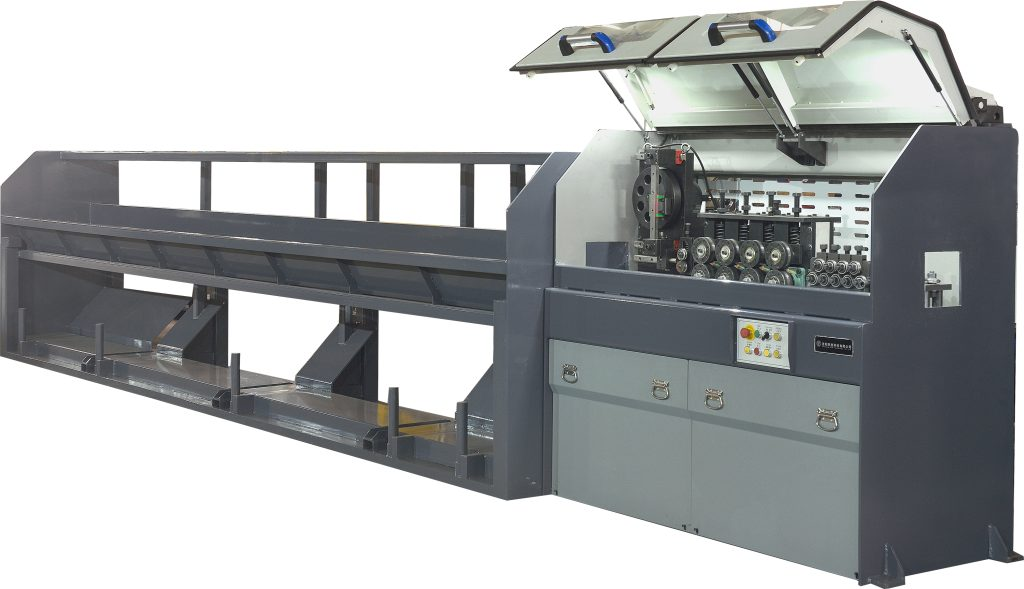

Straightening And Cutting Machine For Steel Bar are essential equipment in the construction industry. These machines are used to straighten and cut steel bars to the required length and size, making them an indispensable tool for any construction project. To ensure the smooth operation and longevity of these machines, proper maintenance is crucial. In this article, we will discuss some maintenance tips for steel bar straightening and cutting machines.

One of the most important maintenance tasks for steel bar straightening and cutting machines is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. It is recommended to clean the machine after each use to prevent build-up. Use a brush or compressed air to remove any debris from the machine’s surfaces and components.

In addition to regular cleaning, lubrication is another key maintenance task for steel bar straightening and cutting machines. Proper lubrication of the machine’s moving parts will help reduce friction and wear, extending the machine’s lifespan. Be sure to use the recommended lubricants for each component and follow the manufacturer’s guidelines for lubrication intervals.

Inspecting the machine for any signs of wear or damage is also important for maintenance. Check the cutting blades, rollers, and other components for any signs of wear or damage. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure smooth operation.

Regular calibration of the machine is essential to maintain accuracy in cutting and straightening steel bars. Over time, the machine’s calibration may drift, leading to inaccuracies in cutting length and size. It is recommended to calibrate the machine regularly to ensure precise cutting and straightening of steel bars.

Another important maintenance tip for Wire Straightening and Cutting Machines are to check the machine’s electrical components regularly. Inspect the wiring, switches, and other electrical components for any signs of wear or damage. Replace any damaged components immediately to prevent electrical issues and ensure the safety of the machine operators.

Proper storage of the machine is also crucial for maintenance. When not in use, store the machine in a clean, dry, and well-ventilated area. Cover the machine to protect it from dust and debris. Avoid storing the machine in areas with extreme temperatures or humidity, as this can damage the machine’s components.

Lastly, it is important to follow the manufacturer’s maintenance guidelines for the specific model of steel bar straightening and cutting machine. These guidelines will provide detailed instructions on how to properly maintain the machine and ensure its optimal performance.

In conclusion, proper maintenance of steel bar straightening and cutting machines is essential to ensure their longevity and efficiency. Regular cleaning, lubrication, inspection, calibration, and storage are key maintenance tasks that should be performed regularly. By following these maintenance tips, you can prolong the life of your steel bar straightening and cutting machine and ensure smooth operation for years to come.

How to Choose the Right Steel Bar Straightening and Cutting Machine for Your Needs

Steel bar straightening and cutting machines are essential equipment in the construction industry, as they help streamline the process of preparing steel bars for use in various applications. These machines are designed to straighten and cut steel bars with precision and efficiency, saving time and labor costs. However, with a wide range of options available in the market, choosing the Automatic Wire Straightening and Cutting Machine for your specific needs can be a daunting task. In this article, we will discuss some key factors to consider when selecting a steel bar straightening and cutting machine.

One of the first things to consider when choosing a steel bar straightening and cutting machine is the type of steel bars you will be working with. Different machines are designed to handle different sizes and types of steel bars, so it is important to choose a machine that is compatible with the steel bars you will be using. Additionally, consider the production capacity of the machine, as this will determine how quickly and efficiently you can process steel bars.

Another important factor to consider is the accuracy and precision of the machine. Look for a machine that offers precise straightening and cutting capabilities, as this will ensure that your steel bars are cut to the exact specifications required for your project. Additionally, consider the speed of the machine, as faster machines can help increase productivity and reduce production time.

When choosing a steel bar straightening and cutting machine, it is also important to consider the durability and reliability of the machine. Look for a machine that is made from high-quality materials and is built to withstand the rigors of daily use. Additionally, consider the reputation of the manufacturer, as reputable manufacturers are more likely to produce high-quality machines that are built to last.

In addition to considering the technical specifications of the machine, it is also important to consider the overall cost of the machine. While it may be tempting to choose a cheaper machine to save money, it is important to consider the long-term costs of maintenance and repairs. Look for a machine that offers a good balance of quality and affordability, and consider the return on investment that the machine will provide.

Finally, consider the after-sales support and service provided by the manufacturer. Look for a manufacturer that offers comprehensive customer support, including training, maintenance, and repair services. Additionally, consider the availability of spare parts and technical support, as this will ensure that your machine remains operational and efficient for years to come.

In conclusion, choosing the right steel bar straightening and cutting machine is essential for ensuring the success of your construction projects. By considering factors such as the type of steel bars you will be working with, the accuracy and precision of the machine, the durability and reliability of the machine, the overall cost, and the after-sales support provided by the manufacturer, you can select a machine that meets your specific needs and requirements. With the right steel bar straightening and cutting machine, you can streamline your production process, increase productivity, and achieve superior results in your construction projects.