Table of Contents

Advantages of Using a Steel Bar Straightening and Cutting Machine

Steel bar straightening and cutting machines are essential tools in the construction industry. These machines are designed to straighten and cut steel bars quickly and accurately, saving time and labor costs. In this article, we will discuss the advantages of using a steel bar straightening and cutting machine.

One of the main advantages of using a steel bar straightening and cutting machine is its efficiency. These machines are capable of straightening and cutting steel bars in a fraction of the time it would take to do so manually. This means that construction projects can be completed faster, leading to increased productivity and profitability.

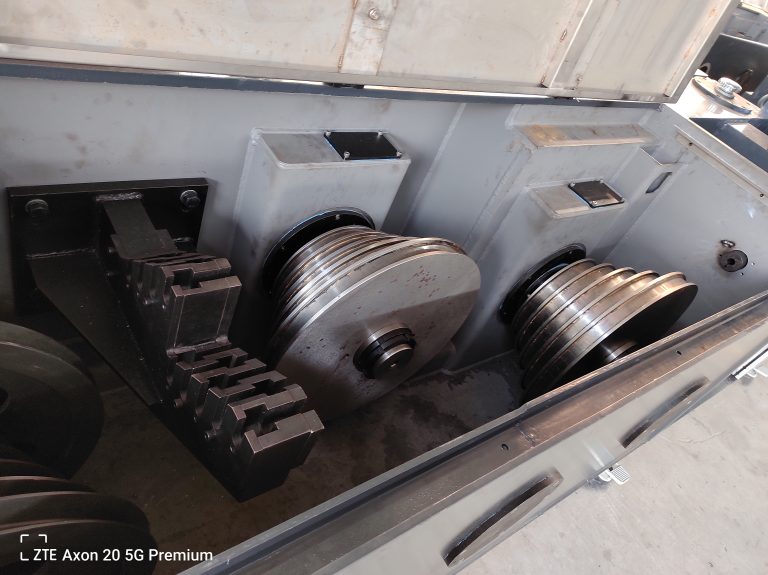

In addition to being faster, Straightening And Cutting Machine For Steel Bar are also more accurate than manual methods. These machines are equipped with precision cutting blades and straightening rollers that ensure each steel bar is cut to the exact length and straightened to the correct specifications. This level of accuracy is crucial in construction projects where precise measurements are required.

Another advantage of using a steel bar straightening and cutting machine is the reduction in labor costs. By automating the process of straightening and cutting steel bars, construction companies can reduce the number of workers needed to complete these tasks. This not only saves money on labor costs but also reduces the risk of human error, resulting in higher quality work.

Steel bar straightening and cutting machines are also versatile tools that can handle a wide range of steel bar sizes and types. Whether you are working with rebar, round bars, or square bars, these machines can easily straighten and cut them to the desired length. This versatility makes them a valuable asset on construction sites where different types of steel bars are used.

Furthermore, steel bar straightening and cutting machines are easy to operate and require minimal maintenance. Most machines come with user-friendly controls that allow operators to adjust cutting and straightening settings with ease. Additionally, these machines are built to withstand the rigors of daily use, ensuring they will last for years to come with proper care and maintenance.

In conclusion, the advantages of using a steel bar straightening and cutting machine are clear. These machines offer increased efficiency, accuracy, and cost savings, making them indispensable tools in the construction industry. By investing in a steel bar straightening and cutting machine, construction companies can streamline their operations, improve productivity, and deliver high-quality work on time and within budget.

How to Choose the Right Steel Bar Straightening and Cutting Machine for Your Business

Steel bar Wire Straightening and Cutting Machines are essential equipment for businesses in the construction, manufacturing, and metalworking industries. These machines are designed to straighten and cut steel bars with precision and efficiency, saving time and labor costs. However, with so many options available on the market, choosing the right machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting a steel bar straightening and cutting machine to ensure that you make the best choice for your business needs.

One of the first things to consider when choosing a steel bar straightening and cutting machine is the size and capacity of the machine. The size of the machine should be determined by the maximum diameter and length of the steel bars that you will be working with. It is important to choose a machine that can handle the size and volume of steel bars that your business requires to ensure optimal performance and efficiency.

Another important factor to consider is the speed and accuracy of the machine. A high-speed machine with precise cutting and straightening capabilities can significantly increase productivity and reduce production time. Look for a machine that offers adjustable cutting and straightening speeds to accommodate different types of steel bars and production requirements.

The durability and reliability of the machine are also crucial considerations. An Automatic Wire Straightening and Cutting Machine is a significant investment for your business, so it is important to choose a machine that is built to last and can withstand the rigors of daily use. Look for machines made from high-quality materials and with a solid construction to ensure long-term reliability and performance.

Ease of operation and maintenance are also important factors to consider when choosing a steel bar straightening and cutting machine. Look for a machine that is user-friendly and easy to operate, with intuitive controls and clear instructions. Additionally, choose a machine that is easy to maintain and service to minimize downtime and ensure continuous operation.

When selecting a steel bar straightening and cutting machine, it is also important to consider the safety features of the machine. Look for machines that are equipped with safety guards, emergency stop buttons, and other safety features to protect operators and prevent accidents in the workplace.

Finally, consider the cost of the machine and your budget constraints. While it is important to invest in a high-quality machine that meets your business needs, it is also important to consider the cost and ensure that the machine offers good value for money. Compare prices from different manufacturers and suppliers, and consider factors such as warranty, after-sales support, and maintenance costs when making your decision.

In conclusion, choosing the right steel bar straightening and cutting machine for your business requires careful consideration of factors such as size, capacity, speed, accuracy, durability, ease of operation, safety features, and cost. By taking the time to research and evaluate different machines, you can make an informed decision that will benefit your business in the long run. Choose a machine that meets your specific requirements and offers the best value for your investment to ensure success and efficiency in your operations.