Table of Contents

Maintenance Tips for Static Coiler Dead Block Machine in High Grade Factory

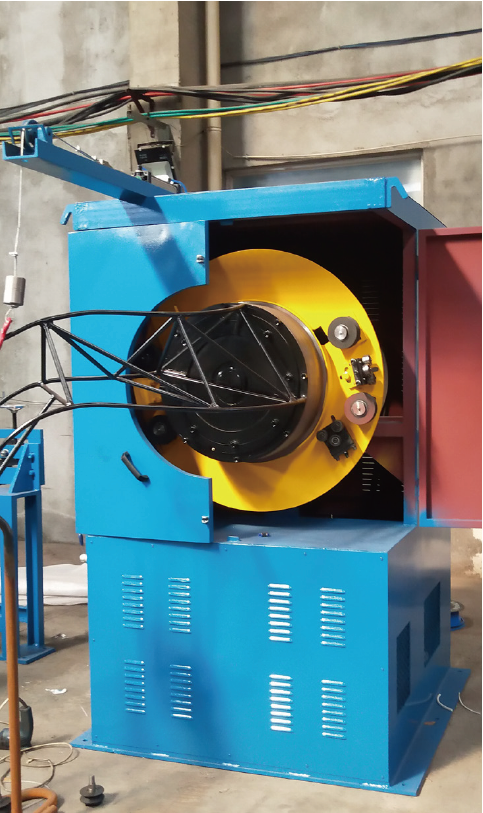

Static coiler dead block machines are an essential component in high-grade factories that specialize in the production of various materials such as steel, aluminum, and copper. These machines play a crucial role in the manufacturing process by coiling the finished product into a neat and organized manner for easy transportation and storage. However, like any other piece of equipment, static coiler dead block machines require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tips for static coiler dead block machines is to regularly inspect and lubricate the moving parts. Over time, the constant movement of the machine can cause wear and tear on the components, leading to decreased efficiency and potential breakdowns. By inspecting and lubricating the moving parts on a regular basis, you can prevent unnecessary damage and extend the lifespan of the machine.

In addition to lubricating the moving parts, it is also important to check the tension of the coils regularly. Proper tension is essential for ensuring that the coils are wound correctly and securely, preventing them from unraveling during transportation or storage. By monitoring the tension of the coils and making any necessary adjustments, you can avoid costly mistakes and ensure that the finished product is of the highest quality.

Another important maintenance tip for Horizontal Dead Block Wire Coiler is to clean the machine regularly. Dust, dirt, and debris can accumulate on the machine over time, causing it to operate less efficiently and potentially leading to malfunctions. By cleaning the machine on a regular basis, you can prevent these issues and keep the machine running smoothly.

It is also important to inspect the electrical components of the machine regularly. Faulty wiring or connections can lead to electrical malfunctions, which can be dangerous and costly to repair. By inspecting the electrical components of the machine and addressing any issues promptly, you can prevent potential hazards and ensure the safety of your employees.

Regularly calibrating the machine is another important maintenance tip for static coiler dead block machines. Calibration ensures that the machine is operating at its optimal performance level, producing coils that meet the required specifications. By calibrating the machine regularly, you can avoid production errors and ensure that the finished product is of the highest quality.

Lastly, it is important to keep detailed records of the maintenance performed on the static coiler dead block machine. By keeping track of when maintenance was last performed and what tasks were completed, you can create a maintenance schedule and ensure that all necessary tasks are completed in a timely manner. This can help prevent breakdowns and prolong the lifespan of the machine.

In conclusion, static coiler dead block machines are an essential component in high-grade factories, and proper maintenance is crucial for ensuring optimal performance and longevity. By following these maintenance tips, you can keep your static coiler dead block machine running smoothly and efficiently, producing high-quality coils for years to come.

How Static Coiler Dead Block Machines Improve Efficiency in Manufacturing Processes

In the world of manufacturing, efficiency is key. Companies are constantly looking for ways to streamline their processes and increase productivity. One way that many manufacturers are achieving this is through the use of static coiler dead block machines. These machines are designed to coil wire or cable quickly and efficiently, saving time and labor costs in the production process.

Static Dead Block Coiler machines are high-grade factory equipment that are specifically designed to handle the coiling of wire or cable. These machines are typically used in industries such as telecommunications, construction, and automotive, where the coiling of wire is a common part of the manufacturing process. By automating this task, manufacturers are able to increase their production output and reduce the risk of human error.

One of the key benefits of static coiler dead block machines is their ability to improve efficiency in the manufacturing process. These machines are able to coil wire or cable at a much faster rate than manual methods, saving time and labor costs for the manufacturer. In addition, static coiler dead block machines are able to produce consistent, high-quality coils, reducing the risk of defects in the final product.

Another benefit of static coiler dead block machines is their ability to handle a wide range of wire or cable sizes. These machines are able to adjust to different diameters and lengths of wire, making them versatile tools for manufacturers who work with a variety of materials. This flexibility allows manufacturers to use the same machine for multiple products, reducing the need for multiple machines and saving space in the factory.

In addition to improving efficiency and versatility, static coiler dead block machines also offer a number of safety benefits for manufacturers. By automating the coiling process, these machines reduce the risk of injury to workers who would otherwise have to manually coil wire or cable. This not only protects the health and safety of employees, but also reduces the risk of costly workplace accidents that can impact a company’s bottom line.

Overall, static coiler dead block machines are a valuable tool for manufacturers looking to improve efficiency in their production processes. These machines offer a number of benefits, including increased productivity, reduced labor costs, and improved safety for workers. By investing in static coiler dead block machines, manufacturers can streamline their operations and stay competitive in today’s fast-paced manufacturing industry.