Table of Contents

Advantages of Using Static Coiler Dead Block Machines in Wire and Cable Manufacturing

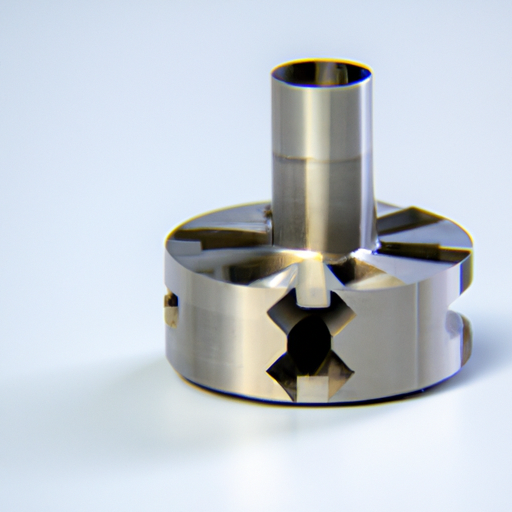

Wire and cable manufacturing is a complex process that requires precision and efficiency to produce high-quality products. One crucial component of this process is the use of static coiler dead block machines. These machines play a vital role in ensuring the smooth and efficient production of wire and cable products. In this article, we will explore the advantages of using static coiler dead block machines in wire and cable manufacturing.

One of the primary advantages of static Dead Block Coiler machines is their ability to increase productivity. These machines are designed to coil wire and cable products quickly and efficiently, allowing manufacturers to produce more products in a shorter amount of time. This increased productivity can lead to higher profits for manufacturers and a more streamlined production process.

In addition to increasing productivity, static coiler dead block machines also help to improve the quality of wire and cable products. These machines are equipped with advanced technology that ensures precise coiling of products, resulting in uniform and consistent coils. This level of precision is essential for ensuring the quality and reliability of wire and cable products, which is crucial for meeting the demands of customers and industry standards.

Another advantage of using Horizontal Dead Block Wire Coiler machines is their versatility. These machines can be customized to accommodate a wide range of wire and cable products, making them suitable for various manufacturing needs. Whether manufacturers are producing small gauge wires or large cables, static coiler dead block machines can be adjusted to meet the specific requirements of each product.

Furthermore, static coiler dead block machines are designed to be user-friendly and easy to operate. Manufacturers can easily set up and adjust these machines to meet their production needs, reducing the time and effort required to operate them. This user-friendly design also helps to minimize the risk of errors and downtime, ensuring a smooth and efficient production process.

Additionally, static coiler dead block machines are built to be durable and reliable. These machines are constructed with high-quality materials and components that are designed to withstand the rigors of continuous use in a manufacturing environment. This durability ensures that static coiler dead block machines can operate efficiently for extended periods, reducing the need for frequent maintenance and repairs.

Overall, static coiler dead block machines offer numerous advantages for manufacturers in the wire and cable industry. From increasing productivity and improving product quality to providing versatility and ease of use, these machines play a crucial role in the production process. By investing in static coiler dead block machines, manufacturers can enhance their production capabilities and meet the demands of an ever-evolving industry.

How to Properly Maintain and Troubleshoot Static Coiler Dead Block Machines

Static coiler dead block machines are essential equipment in the wire and cable industry, used for coiling wire or cable onto a spool or reel. Proper maintenance and troubleshooting of these machines are crucial to ensure smooth operation and prevent costly downtime. In this article, we will discuss some key maintenance tips and common troubleshooting techniques for static coiler dead block machines.

Regular maintenance is essential to keep static coiler dead block machines in optimal working condition. One of the most important maintenance tasks is to regularly inspect and lubricate moving parts such as bearings, gears, and drive belts. Proper lubrication helps reduce friction and wear, extending the lifespan of these components. It is also important to check for any signs of wear or damage and replace any worn-out parts promptly to prevent further damage to the machine.

In addition to regular lubrication, it is important to keep the machine clean and free of debris. Dust and dirt can accumulate on the machine over time, causing parts to wear out faster and affecting the machine’s performance. Regular cleaning with a soft brush or cloth can help prevent this buildup and keep the machine running smoothly.

Another important maintenance task is to check and adjust the tension of the wire or cable being coiled. Proper tension is crucial for achieving uniform and tightly wound coils. Improper tension can lead to loose coils, tangling, or other issues that can affect the quality of the finished product. Regularly checking and adjusting the tension settings can help prevent these problems and ensure consistent coil quality.

When it comes to troubleshooting static coiler dead block machines, one common issue is coil slippage. This can occur when the coil is not properly secured on the spool or reel, causing it to slip or unwind during the coiling process. To prevent coil slippage, it is important to ensure that the coil is securely fastened to the spool or reel before starting the coiling process. Additionally, checking and adjusting the tension settings can help prevent coil slippage by ensuring that the wire or cable is properly guided onto the spool.

Another common issue with static coiler dead block machines is uneven coiling. This can occur when the wire or cable is not evenly distributed on the spool or reel, resulting in coils that are loose or unevenly wound. To troubleshoot this issue, it is important to check the alignment of the wire or cable as it enters the coiling machine and make any necessary adjustments to ensure that it is evenly distributed on the spool. Additionally, checking and adjusting the tension settings can help prevent uneven coiling by ensuring that the wire or cable is properly guided onto the spool.

In conclusion, proper maintenance and troubleshooting of static coiler dead block machines are essential to ensure smooth operation and prevent costly downtime. By following the maintenance tips and troubleshooting techniques outlined in this article, you can keep your machine running smoothly and produce high-quality coils consistently. Remember to regularly inspect and lubricate moving parts, keep the machine clean, check and adjust tension settings, and address common issues such as coil slippage and uneven coiling promptly to maintain optimal performance.