Tips for\u00a0Static Coiler Dead Block Machines

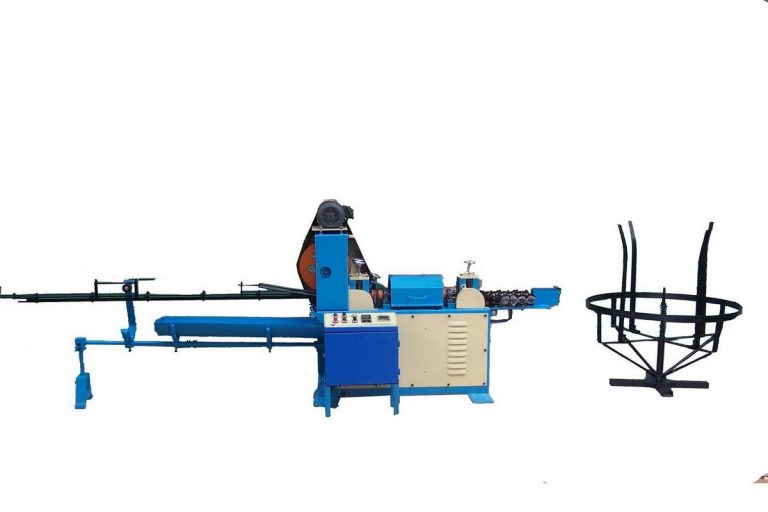

Static coiler dead block machines are essential equipment in the wire and cable industry, used for coiling and packaging wire products efficiently. To ensure the smooth operation of these machines and prevent costly downtime, regular maintenance is crucial. In this article, we will discuss some maintenance tips for static coiler dead block machines to help you keep your equipment in top condition.

One of the most important maintenance tasks for static coiler dead block machines is regular lubrication. Proper lubrication of moving parts such as bearings, gears, and chains is essential to reduce friction and wear, prolonging the lifespan of the machine. It is recommended to follow the manufacturer\u2019s guidelines for the type and frequency of lubrication required for each component.

In addition to lubrication, it is important to inspect the machine regularly for any signs of wear or damage. Check for loose or worn-out parts, such as belts, pulleys, and springs, and replace them as needed. Pay attention to any unusual noises or vibrations during operation, as these could indicate a potential issue that needs to be addressed.

Another important maintenance task for\u00a0Steel Wire\u00a0Dead Block Coiler\u00a0For Continuous Coiling\u00a0machines is cleaning. Dust, dirt, and debris can accumulate on the machine over time, affecting its performance and efficiency. Regularly clean the machine with a soft brush or cloth to remove any buildup and ensure smooth operation.

It is also important to check the tension of the wire during coiling to prevent overstretching or snapping. Adjust the tension settings as needed to ensure that the wire is coiled properly without any issues. Regularly inspect the wire guides and rollers for any signs of wear or damage, as these components play a crucial role in the coiling process.

Regularly inspect the electrical components of the machine, such as motors, sensors, and control panels, for any signs of wear or damage. Check for loose connections, frayed wires, or burnt-out components, and replace them as needed. It is also important to test the safety features of the machine, such as emergency stop buttons and safety guards, to ensure they are functioning properly.

In addition to regular maintenance tasks, it is important to schedule periodic inspections by a qualified technician to identify any potential issues before they escalate into major problems. A professional inspection can help you identify worn-out parts, faulty components, or other issues that may require immediate attention.

By following these maintenance tips for static coiler dead block machines, you can ensure the smooth operation of your equipment and prolong its lifespan. Regular lubrication, inspection, cleaning, and testing of the machine are essential to prevent costly downtime and ensure optimal performance. Remember to follow the manufacturer\u2019s guidelines and seek professional help when needed to keep your static coiler dead block machine in top condition.