Table of Contents

Key Components and Features of Slip type Wire Drawing Machines

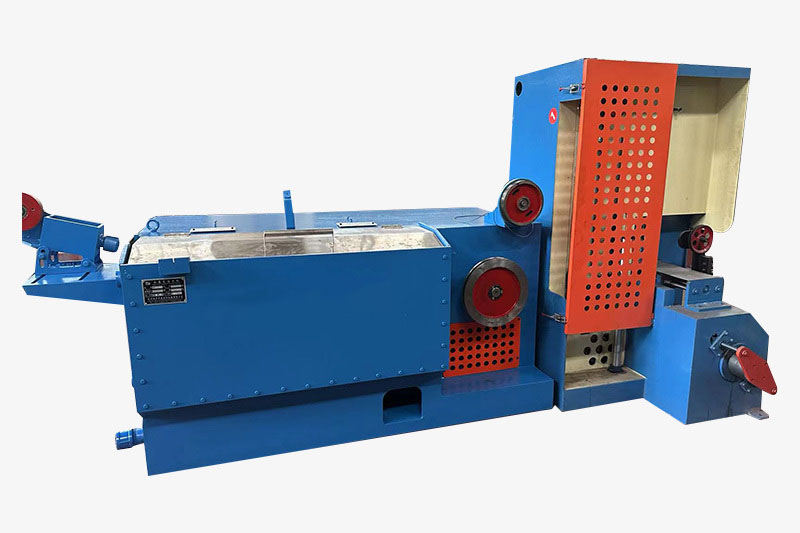

Slip Wire Drawing Machine is essential equipment in the manufacturing industry for producing high-quality stainless steel wires. These machines are designed to reduce the diameter of stainless steel rods or wires by pulling them through a series of dies to achieve the desired size and finish. The production of stainless steel wire drawing machines involves several key components and features that are crucial for their efficient operation and performance.

One of the key components of a stainless steel wire drawing machine is the drawing die. Drawing dies are precision tools made of hard materials such as tungsten carbide or diamond that are used to reduce the diameter of the wire as it passes through them. The quality of the drawing die directly affects the quality of the finished wire, so it is essential to use high-quality dies that are properly maintained to ensure consistent and accurate wire drawing.

Another important component of a stainless steel wire drawing machine is the capstan. The capstan is a rotating drum or pulley that provides the pulling force necessary to draw the wire through the dies. The speed and tension of the capstan can be adjusted to control the rate of wire reduction and ensure a smooth and uniform finish. Modern stainless steel wire drawing machines are equipped with advanced capstan systems that offer precise control over the drawing process for optimal results.

In addition to the drawing die and capstan, stainless steel wire drawing machines also feature a spooling system. The spooling system is responsible for winding the drawn wire onto spools or coils for storage and transportation. Proper spooling is essential to prevent tangling and ensure that the wire remains in good condition during handling and storage. Stainless steel wire drawing machines are equipped with automatic spooling systems that can handle various wire sizes and spool configurations to meet the specific requirements of different applications.

One of the key features of stainless steel wire drawing machines is their versatility. These machines are capable of drawing wires of different diameters and materials, making them suitable for a wide range of applications in industries such as automotive, aerospace, construction, and electronics. Stainless steel wire drawing machines can produce wires with precise tolerances and surface finishes to meet the stringent requirements of modern manufacturing processes.

Another important feature of stainless steel wire drawing machines is their durability and reliability. These machines are built to withstand the high forces and temperatures involved in the wire drawing process, ensuring long-term performance and minimal downtime. Stainless steel wire drawing machines are designed with robust frames, heavy-duty components, and advanced cooling systems to ensure continuous operation under demanding conditions.

In conclusion, stainless steel wire drawing machines are essential equipment for producing high-quality stainless steel wires in various industries. These machines are equipped with key components such as drawing dies, capstans, and spooling systems that are crucial for their efficient operation. The versatility, durability, and reliability of stainless steel wire drawing machines make them indispensable tools for modern manufacturing processes.

Benefits of Using Stainless Steel Wire Drawing Machines

Stainless steel wire drawing machines are essential tools in the manufacturing industry, used to produce high-quality stainless steel wire for a variety of applications. These machines are designed to pull a wire through a series of dies to reduce its diameter and improve its surface finish. The process involves applying tension to the wire and pulling it through a die, which compresses the material and reduces its diameter. This results in a smoother, more uniform wire that is ideal for use in a wide range of industries.

One of the key benefits of using stainless steel wire drawing machines is the ability to produce wire with precise dimensions. These machines are capable of reducing the diameter of a wire to very tight tolerances, ensuring that the final product meets the exact specifications required for a particular application. This level of precision is essential in industries such as aerospace, automotive, and electronics, where even small variations in wire diameter can have a significant impact on performance.

In addition to producing wire with precise dimensions, stainless steel wire drawing machines also offer the advantage of improving the surface finish of the wire. As the wire is pulled through the dies, any imperfections or irregularities on the surface are smoothed out, resulting in a wire with a clean, uniform appearance. This is important in applications where the wire will be visible or where a smooth surface is necessary for proper functioning, such as in medical devices or architectural applications.

Another benefit of using stainless steel wire drawing machines is the ability to control the mechanical properties of the wire. By adjusting the speed at which the wire is pulled through the dies and the amount of tension applied, manufacturers can tailor the properties of the wire to meet specific requirements. This allows for the production of wire with the desired strength, ductility, and other mechanical properties, making it suitable for a wide range of applications.

Stainless steel wire drawing machines are also highly efficient, allowing manufacturers to produce large quantities of wire quickly and cost-effectively. These machines are designed to operate continuously, with minimal downtime for maintenance or adjustments. This means that manufacturers can meet tight production deadlines and keep up with demand without sacrificing quality or consistency.

Furthermore, stainless steel wire drawing machines are versatile tools that can be used to produce wire in a wide range of sizes and shapes. Whether manufacturers need thin wire for delicate electronics or thick wire for heavy-duty industrial applications, these machines can be adjusted to accommodate a variety of requirements. This flexibility makes stainless steel wire drawing machines a valuable asset for manufacturers in diverse industries.

In conclusion, stainless steel wire drawing machines offer a range of benefits for manufacturers looking to produce high-quality stainless steel wire. From precise dimensions and improved surface finish to controlled mechanical properties and efficient production, these machines provide the tools needed to meet the demands of modern manufacturing. With their versatility and reliability, stainless steel wire drawing machines are an essential component of any manufacturing operation that requires high-quality wire products.

Maintenance Tips for Stainless Steel Wire Drawing Machines

Stainless steel wire drawing machines are essential equipment in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. These machines are crucial for producing high-quality stainless steel wire used in various applications such as automotive, aerospace, and construction. To ensure the smooth operation and longevity of these machines, proper maintenance is essential.

One of the key maintenance tips for Wet Wire Drawing Machines is regular cleaning. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential damage. It is important to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts of the machine with a suitable lubricant will help reduce friction and wear, prolonging the machine’s lifespan.

Another important aspect of maintenance for stainless steel wire drawing machines is inspecting and replacing worn or damaged parts. Regularly inspecting the machine for signs of wear, such as frayed wires or worn dies, can help prevent costly breakdowns and downtime. It is recommended to replace any damaged parts promptly to ensure the machine continues to operate efficiently.

Furthermore, monitoring the machine’s performance is crucial for identifying any potential issues early on. Keeping track of the machine’s output, speed, and noise levels can help detect any abnormalities that may indicate a problem. Addressing these issues promptly can prevent further damage and ensure the machine continues to produce high-quality wire.

In addition to regular maintenance, it is important to follow the manufacturer’s guidelines for operating the machine. This includes using the correct wire size and type, as well as operating the machine at the recommended speed and tension. Failure to follow these guidelines can lead to premature wear and damage to the machine.

Lastly, scheduling routine maintenance checks with a qualified technician can help ensure the machine is in optimal condition. A technician can inspect the machine thoroughly, identify any potential issues, and perform any necessary repairs or adjustments. Regular maintenance checks can help prevent unexpected breakdowns and prolong the machine’s lifespan.

In conclusion, proper maintenance is essential for ensuring the smooth operation and longevity of stainless steel wire drawing machines. Regular cleaning, inspecting and replacing worn parts, monitoring performance, following manufacturer guidelines, and scheduling routine maintenance checks are all important aspects of maintaining these machines. By following these maintenance tips, manufacturers can ensure their stainless steel wire drawing machines continue to produce high-quality wire for years to come.