Table of Contents

How to Properly Troubleshoot a Spooling Machine in Wire Drawing Process

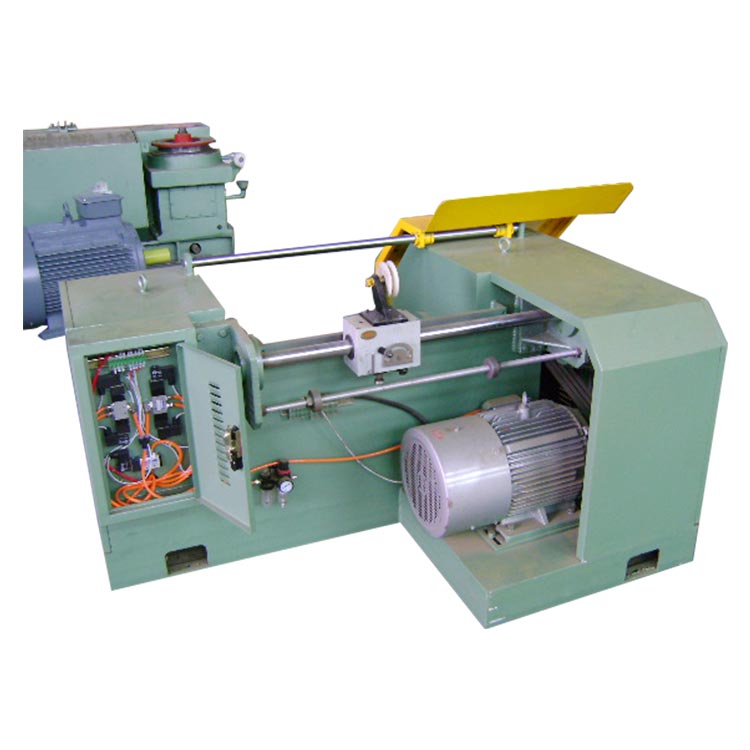

A Bobbin Spooling Machine is an essential component in the wire drawing process, responsible for winding the drawn wire onto spools for storage or further processing. Proper maintenance and troubleshooting of the spooling machine are crucial to ensure smooth operation and prevent downtime in the wire drawing process.

Regular maintenance of the spooling machine is necessary to keep it in optimal working condition. This includes cleaning the machine regularly to remove any dirt, dust, or debris that may accumulate on the spools, rollers, and other components. Lubricating moving parts such as bearings and gears is also important to reduce friction and wear, ensuring smooth operation of the machine.

Inspecting the spooling machine for any signs of wear or damage is another key aspect of maintenance. Check for loose or damaged parts, worn-out bearings, or misaligned rollers, and replace or repair them as needed to prevent further damage to the machine. It is also important to check the tension of the wire being wound onto the spools to ensure proper winding and prevent breakage.

In addition to regular maintenance, troubleshooting the spooling machine is necessary to identify and address any issues that may arise during operation. Common problems with spooling machines include uneven winding, wire breakage, spool slippage, and jamming. These issues can be caused by a variety of factors, such as improper tension, misaligned rollers, or worn-out components.

When troubleshooting a spooling machine, start by checking the tension of the wire being wound onto the spools. Adjust the tension as needed to ensure proper winding and prevent breakage. If the wire is winding unevenly, check for misaligned rollers or worn-out bearings that may be causing the issue. Adjust or replace these components as needed to correct the problem.

If the spools are slipping or jamming during operation, check for any obstructions or debris that may be causing the issue. Clean the spools and rollers thoroughly to remove any dirt or debris that may be interfering with the winding process. If the problem persists, check for worn-out components such as gears or bearings that may need to be replaced.

Properly maintaining and troubleshooting a Wire Spooling Machine is essential to ensure smooth operation and prevent downtime in the wire drawing process. By regularly cleaning, lubricating, and inspecting the machine, as well as addressing any issues that may arise during operation, you can keep your spooling machine in optimal working condition and maximize its efficiency and productivity.

In conclusion, the spooling machine is a critical component in the wire drawing process, responsible for winding the drawn wire onto spools for storage or further processing. Proper maintenance and troubleshooting of the spooling machine are essential to ensure smooth operation and prevent downtime. By following the tips outlined in this article, you can keep your spooling machine in optimal working condition and maximize its efficiency and productivity.

Benefits of Using a Spooling Machine in Wire Drawing Process

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One crucial step in the wire drawing process is spooling, where the drawn wire is wound onto a spool for storage and transportation.

Spooling machines play a vital role in the wire drawing process by efficiently winding the drawn wire onto spools. These machines are designed to handle wires of different diameters and materials, making them versatile and essential equipment in wire drawing operations. There are several benefits to using a Horizontal Spooler Of Wire Drawing Machine Process.

One of the primary benefits of using a spooling machine is increased productivity. Spooling machines are designed to wind wire onto spools quickly and efficiently, reducing the time and labor required for this task. This allows manufacturers to produce more wire in less time, increasing their overall productivity and output.

In addition to increased productivity, spooling machines also help improve the quality of the drawn wire. By winding the wire onto spools in a controlled manner, these machines help prevent tangling and kinking, which can lead to defects in the wire. This results in a higher-quality product that meets the required specifications and standards.

Another benefit of using a spooling machine is improved safety. Manual spooling of wire can be a hazardous task, as workers are required to handle sharp and potentially dangerous materials. Spooling machines eliminate the need for manual winding, reducing the risk of injuries and accidents in the workplace.

Furthermore, spooling machines help reduce waste in the wire drawing process. By winding the wire onto spools in a precise and controlled manner, these machines minimize the amount of scrap and offcuts produced during the process. This not only helps reduce material costs but also contributes to a more sustainable and environmentally friendly manufacturing process.

Spooling machines also offer greater flexibility in the wire drawing process. These machines can be easily adjusted to accommodate wires of different diameters and materials, allowing manufacturers to produce a wide range of wire products with ease. This flexibility is essential for meeting the diverse needs of customers and adapting to changing market demands.

Overall, the use of a spooling machine in the wire drawing process offers numerous benefits, including increased productivity, improved quality, enhanced safety, reduced waste, and greater flexibility. These machines play a crucial role in the manufacturing industry, helping manufacturers produce high-quality wire products efficiently and effectively. By investing in a spooling machine, manufacturers can streamline their wire drawing operations and stay competitive in the market.