Maintenance Tips for Slip Wire Drawing Machine In Industrial

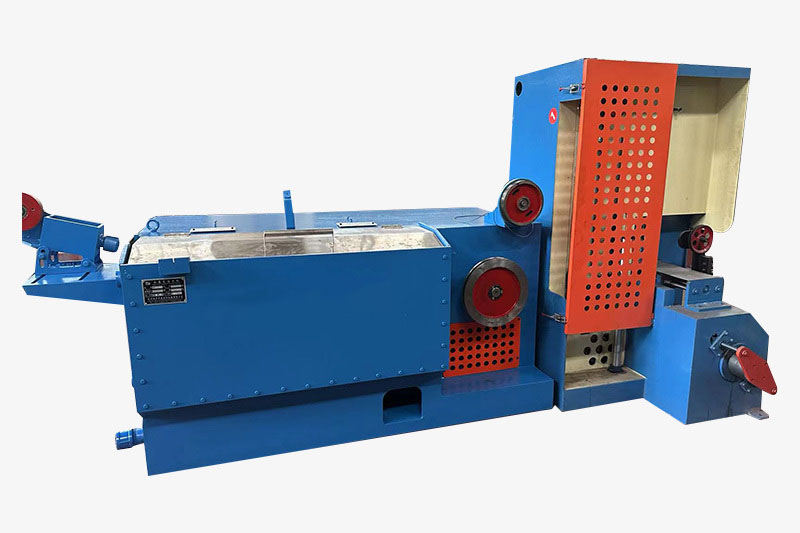

Water-tank wire drawing machines are essential equipment in the wire manufacturing industry. These machines are used to draw wire through a series of dies to reduce its diameter and improve its quality. Proper maintenance of water-tank wire drawing machines is crucial to ensure their optimal performance and longevity. In this article, we will discuss some maintenance tips for Wet Wire Drawing Machine to help you keep them in top condition.

Regular cleaning of the water tank is essential to prevent the buildup of dirt, debris, and other contaminants that can affect the quality of the wire being drawn. It is recommended to clean the water tank at least once a week to remove any impurities that may have accumulated. Use a mild detergent and a soft brush to scrub the tank thoroughly, and rinse it with clean water to remove any residue.

Inspect the water tank for any signs of corrosion or damage regularly. Corrosion can weaken the tank and lead to leaks, which can affect the drawing process and the quality of the wire. If you notice any signs of corrosion, such as rust spots or pitting, it is important to address the issue promptly. You may need to replace the affected parts or apply a protective coating to prevent further corrosion.

Check the water level in the tank regularly to ensure that it is at the appropriate level. The water level should be sufficient to provide adequate cooling during the wire drawing process. If the water level is too low, it can lead to overheating of the dies and affect the quality of the wire. Add water as needed to maintain the proper level and ensure optimal cooling.

Inspect the water circulation system of the wire drawing machine to ensure that it is functioning properly. The water circulation system is responsible for cooling the dies and maintaining the temperature of the water in the tank. Check the pump, hoses, and fittings for any signs of leaks or damage, and replace any faulty components as needed. Proper water circulation is essential to prevent overheating of the dies and ensure consistent wire quality.

Regularly lubricate the moving parts of the slip Wire Drawing Machine to reduce friction and wear. Lubrication helps to prolong the life of the machine and ensure smooth operation. Use a high-quality lubricant recommended by the manufacturer and apply it to the bearings, gears, and other moving parts according to the manufacturer’s instructions. Avoid over-lubricating, as this can attract dirt and debris that can affect the performance of the machine.

In conclusion, proper maintenance of water-tank wire drawing machines is essential to ensure their optimal performance and longevity. By following these maintenance tips, you can keep your wire drawing machine in top condition and prolong its service life. Regular cleaning, inspection, lubrication, and monitoring of the water circulation system and electrical components are key aspects of maintaining a water-tank wire drawing machine. By taking care of your machine, you can ensure consistent wire quality and maximize productivity in your wire manufacturing operations.