The merits of Using Slip Wire Drawing Machine for Zinc Wire Processing

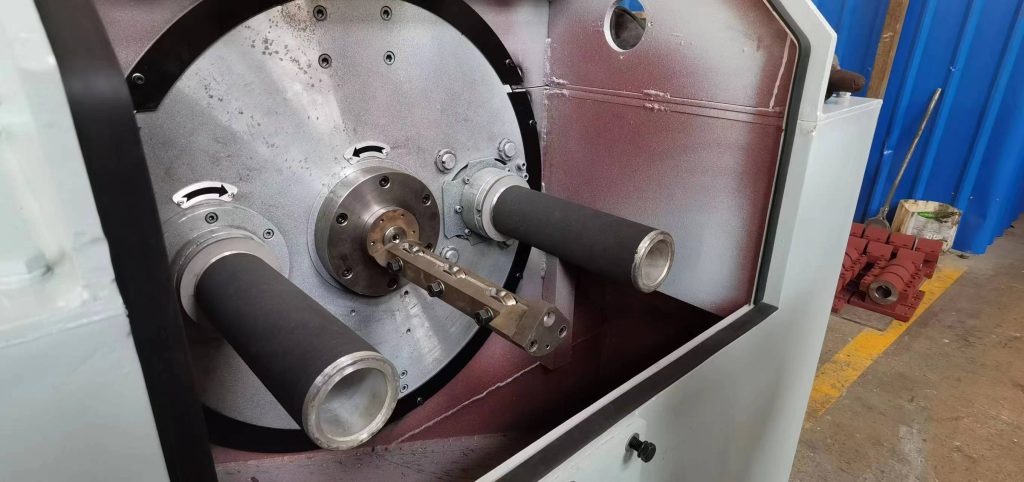

Zinc wire is a versatile material that is used in a variety of industries, including construction, automotive, and electronics. To meet the demand for high-quality zinc wire, manufacturers rely on slip wire drawing machines. These machines are essential for processing zinc wire efficiently and effectively.

One of the key benefits of using a slip wire drawing machine for zinc wire processing is its ability to produce wire with consistent diameter and surface finish. This is crucial for ensuring the quality and performance of the final product. By using a slip wire drawing machine, manufacturers can control the drawing process more precisely, resulting in a more uniform wire that meets the required specifications.

In addition to producing high-quality wire, slip wire drawing machines are also highly efficient. These machines are designed to operate at high speeds, allowing manufacturers to process large quantities of zinc wire in a short amount of time. This not only increases productivity but also reduces production costs, making slip wire drawing machines a cost-effective solution for zinc wire processing.

Furthermore, Wet Drawing Machine For Zinc Wire Manufacturing are versatile and can be used to produce wire in a wide range of diameters. This flexibility allows manufacturers to meet the specific requirements of their customers and produce wire for a variety of applications. Whether it’s thin wire for electronics or thick wire for construction, a slip wire drawing machine can handle the job with ease.

Another benefit of using a slip wire drawing machine for zinc wire processing is its durability and reliability. These machines are built to withstand the rigors of continuous operation and are designed to require minimal maintenance. This ensures that manufacturers can rely on their slip wire drawing machine to deliver consistent results day in and day out.

Additionally, slip wire drawing machines are easy to operate and require minimal training to use. This makes them accessible to a wide range of manufacturers, regardless of their level of expertise. With simple controls and intuitive design, operators can quickly learn how to operate a slip wire drawing machine and start producing high-quality zinc wire in no time.

Overall, the benefits of using a slip wire drawing machine for zinc wire processing are clear. From producing high-quality wire to increasing efficiency and reducing costs, these machines offer a range of advantages for manufacturers in the zinc wire industry. With their versatility, durability, and ease of use, slip wire drawing machines are an essential tool for any manufacturer looking to produce top-quality zinc wire.