Benefits of Using Slip Wire Drawing Machine for Zinc Wire Processing

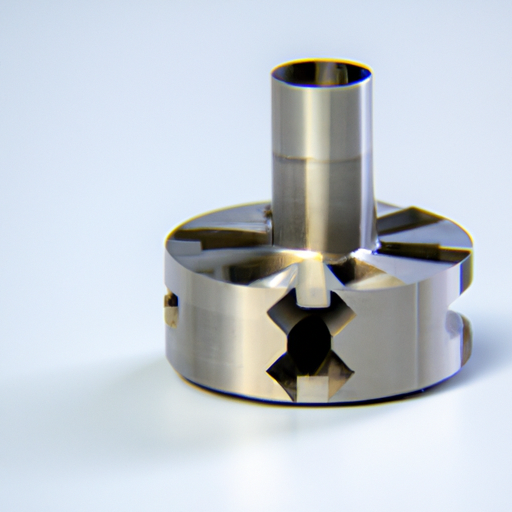

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wires, including zinc wires. One of the key machines used in this process is the slip wire drawing machine, which offers several benefits for zinc wire processing.

One of the main advantages of using a Pure Zinc Wire Drawing Machine is its ability to produce wires with consistent diameter and smooth surface finish. This is crucial for applications where precision and quality are paramount, such as in the production of electrical wires or cables. The machine’s design allows for precise control over the drawing process, resulting in uniform wire diameter and minimal surface imperfections.

In addition to producing high-quality wires, slip wire drawing machines are also known for their efficiency and productivity. These machines are capable of drawing wires at high speeds, allowing for faster production rates compared to traditional drawing methods. This can lead to increased output and reduced production costs, making the machine a cost-effective solution for manufacturers looking to streamline their operations.

Furthermore, slip wire drawing machines are versatile and can be used for processing a wide range of wire materials, including zinc. This flexibility makes them a valuable asset for manufacturers working with different types of wires, as they can easily switch between materials without the need for extensive retooling or adjustments. This can help save time and resources, allowing for greater flexibility in production planning.

Another benefit of using a slip wire drawing machine for zinc wire processing is its durability and reliability. These machines are built to withstand the rigors of continuous operation, ensuring consistent performance over time. This reliability is essential for maintaining production schedules and meeting customer demands, as any downtime can result in costly delays and lost revenue.

Additionally, slip wire drawing machines are relatively easy to operate and maintain, making them suitable for manufacturers of all sizes. With proper training and regular maintenance, operators can ensure that the machine runs smoothly and efficiently, maximizing its lifespan and performance. This ease of use can help reduce training costs and minimize downtime due to maintenance issues.

Overall, the benefits of using a slip wire drawing machine for zinc wire processing are clear. From producing high-quality wires with consistent diameter and surface finish to improving efficiency and productivity, these machines offer a range of advantages for manufacturers looking to enhance their wire drawing operations. With their versatility, durability, and ease of use, slip wire drawing machines are a valuable investment for any manufacturer working with zinc wires.