Selecting The Right Slip Wire Drawing Machines For Your Needs

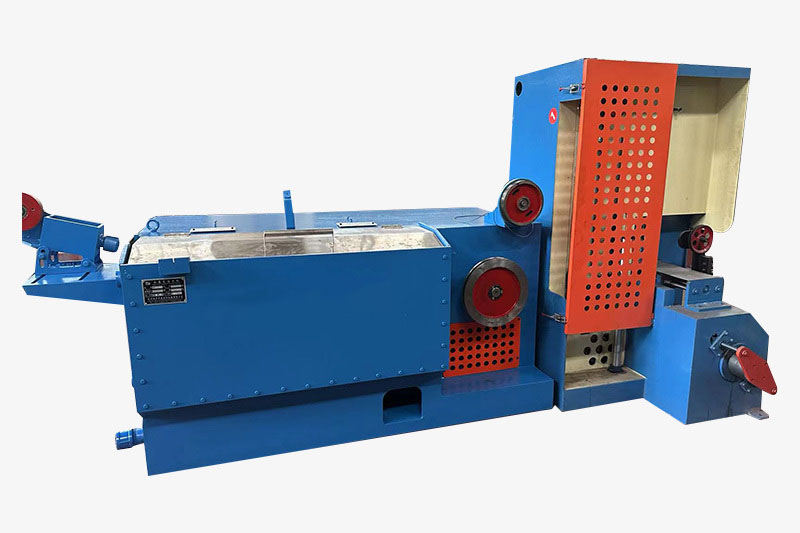

Slip Wire Drawing Machines are essential tools in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. This process is crucial for producing wires of various sizes and shapes, which are used in a wide range of applications, from electrical wiring to construction materials. If you are in the market for a wire drawing machine, it is important to select the right one for your specific needs.

When choosing a slip wire drawing machine, there are several factors to consider. The first step is to determine the type of wire you will be working with. Different machines are designed for different types of wire, so it is important to select a machine that is compatible with the material you will be using. Additionally, consider the diameter of the wire you will be working with, as this will impact the size of the machine you need.

Another important factor to consider is the speed at which you need the Wet Wire Drawing Machine to operate. Some wire drawing machines are designed for high-speed production, while others are better suited for slower, more precise work. Consider your production needs and select a machine that can keep up with the demand.

It is also important to consider the number of dies the machine has. The more dies a machine has, the more times the wire can be drawn through, resulting in a finer wire. If you need to produce wires of varying diameters, a machine with multiple dies may be the best option for you.

In addition to these factors, it is important to consider the overall quality of the machine. Look for a machine that is well-built and durable, as this will ensure that it can withstand the rigors of daily use. Additionally, consider the reputation of the manufacturer, as a reputable company is more likely to produce high-quality machines.

Once you have considered these factors, it is time to select a wire drawing machine that meets your needs. There are many manufacturers that produce wire drawing machines, so take the time to research and compare different options. Look for machines that have the features you need at a price point that fits your budget.

When you have selected a machine, it is important to properly set it up and maintain it to ensure optimal performance. Follow the manufacturer’s instructions for installation and operation, and regularly inspect and clean the machine to prevent any issues from arising.

In conclusion, selecting the right is crucial for producing high-quality wires efficiently. Consider the type of wire you will be working with, the speed at which you need the machine to operate, the number of dies it has, and the overall quality of the machine. Take the time to research and compare different options before making a decision, and be sure to properly set up and maintain the machine for optimal performance.