Table of Contents

Advantages of Using Slip Wire Drawing Machines in Wire Production

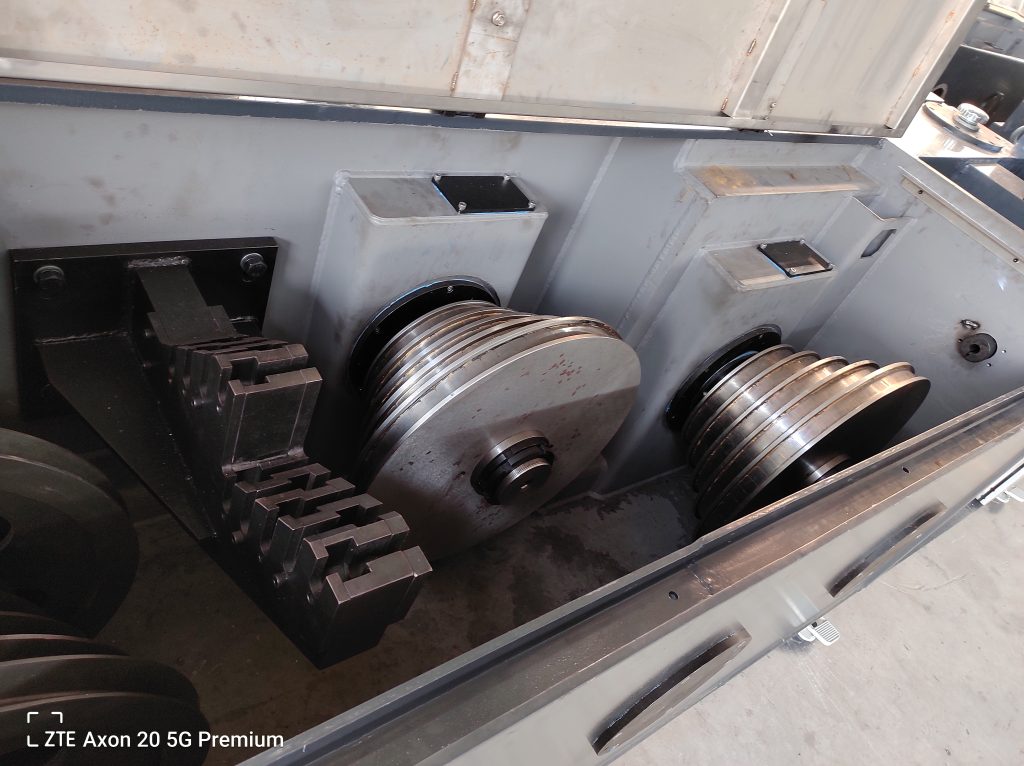

Wire drawing is a process used in the manufacturing of wire products, where a metal wire is pulled through a series of dies to reduce its diameter. This process is essential in producing wires of various sizes and shapes for a wide range of applications. One of the key machines used in wire drawing is the slip wire drawing machine, which offers several advantages in wire production.

The slip wire drawing machine is a type of wire drawing machine that utilizes a slip ring to control the speed of the wire being drawn. This allows for precise control over the drawing process, resulting in wires with consistent diameter and surface finish. One of the main advantages of using a Wet Wire Drawing Machine is its ability to produce wires with tight tolerances. This is crucial in industries where precision is paramount, such as in the manufacturing of medical devices, aerospace components, and electronic products.

Another advantage of the slip wire drawing machine is its versatility. This machine can be used to draw wires of various materials, including steel, copper, aluminum, and titanium. This makes it a valuable tool for wire manufacturers who need to produce wires for different applications. Additionally, the slip wire drawing machine can be easily adjusted to accommodate different wire sizes, making it a flexible and cost-effective solution for wire production.

In addition to its precision and versatility, the slip wire drawing machine also offers efficiency in the wire drawing process. The use of a slip ring allows for smooth and continuous drawing of the wire, reducing downtime and increasing productivity. This is especially important in industries where high volumes of wire need to be produced quickly and efficiently.

Furthermore, the slip wire drawing machine is designed for ease of operation and maintenance. The machine is equipped with user-friendly controls that allow operators to adjust drawing parameters easily. Additionally, the machine is built with high-quality components that are durable and reliable, reducing the need for frequent maintenance and repairs.

Overall, the slip wire drawing machine is a valuable tool for wire manufacturers looking to produce high-quality wires with precision and efficiency. Its ability to produce wires with tight tolerances, versatility in handling different materials and sizes, efficiency in the drawing process, and ease of operation and maintenance make it an ideal choice for a wide range of wire production applications.

In conclusion, the slip wire drawing machine offers several advantages in wire production, making it a valuable asset for wire manufacturers. Its precision, versatility, efficiency, and ease of operation and maintenance make it a reliable and cost-effective solution for producing high-quality wires for various industries. Whether you are producing wires for medical devices, aerospace components, or electronic products, the slip wire drawing machine is a tool that can help you meet your wire production needs with precision and efficiency.

Maintenance Tips for Slip Wire Drawing Machine

A slip wire drawing machine is a crucial piece of equipment in the wire manufacturing industry. It is used to pull wire through a series of dies to reduce its diameter and improve its quality. To ensure the smooth operation of a slip wire drawing machine, regular maintenance is essential. In this article, we will discuss some maintenance tips to keep your slip wire drawing machine in top condition.

One of the most important maintenance tasks for a slip wire drawing machine is to regularly inspect and lubricate the machine’s components. This includes checking the bearings, gears, and other moving parts for signs of wear and tear. Proper lubrication is essential to reduce friction and prevent premature wear on these components. It is recommended to use high-quality lubricants that are suitable for the specific requirements of the machine.

In addition to lubrication, it is important to regularly clean the machine to remove any dirt, dust, or debris that may have accumulated. This will help prevent clogs and blockages that can affect the machine’s performance. It is also important to check the machine’s cooling system to ensure that it is functioning properly. Overheating can cause damage to the machine’s components and affect its overall performance.

Another important maintenance task for a slip wire drawing machine is to regularly check the tension of the wire being drawn. Proper tension is essential to ensure that the wire is pulled through the dies smoothly and consistently. If the tension is too high or too low, it can cause the wire to break or become misshapen. Regularly adjusting the tension settings will help maintain the quality of the wire being produced.

It is also important to regularly inspect the dies used in the machine. Over time, the dies can become worn or damaged, which can affect the quality of the wire being produced. It is important to replace worn or damaged dies promptly to ensure that the machine continues to operate efficiently. Regularly inspecting the dies will also help identify any potential issues before they become major problems.

Regular maintenance of a slip wire drawing machine also includes checking the electrical components of the machine. This includes inspecting the wiring, connections, and controls for signs of damage or wear. It is important to ensure that the electrical components are functioning properly to prevent any safety hazards or malfunctions.

In conclusion, regular maintenance is essential to keep a slip wire drawing machine in top condition. By following these maintenance tips, you can ensure that your machine operates efficiently and produces high-quality wire. Proper lubrication, cleaning, tension adjustment, die inspection, and electrical component checks are all important tasks that should be performed regularly. By taking care of your slip wire drawing machine, you can extend its lifespan and maximize its performance.