Table of Contents

How to Properly Maintain and Care for Semi-Automatic Welding Wire Precision Layer Winding Machine

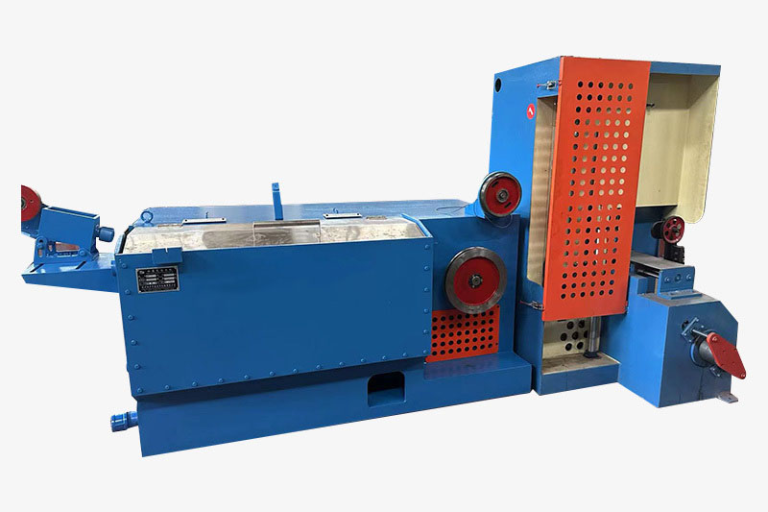

Semi-automatic welding wire precision layer winding machines are essential tools in the welding industry, used to wind welding wire onto spools with precision and accuracy. Proper maintenance and care of these machines are crucial to ensure their longevity and optimal performance. In this article, we will discuss some key tips on how to properly maintain and care for a semi-automatic welding wire precision layer winding machine.

First and foremost, it is important to regularly clean the machine to prevent the buildup of dirt, dust, and debris. This can be done by using a soft brush or cloth to remove any particles that may have accumulated on the machine’s surface. Additionally, it is recommended to use a mild detergent or cleaning solution to wipe down the machine and remove any stubborn stains or residue.

In addition to cleaning, it is important to regularly inspect the machine for any signs of wear and tear. This includes checking for loose or damaged parts, such as belts, gears, and bearings. If any parts are found to be worn or damaged, they should be replaced immediately to prevent further damage to the machine.

Another important aspect of maintaining a semi-automatic welding wire precision layer winding machine is to lubricate the moving parts regularly. This includes applying lubricant to the gears, bearings, and other moving components to ensure smooth operation and prevent friction. It is important to use the correct type of lubricant for each specific part to avoid damage or malfunction.

Furthermore, it is important to calibrate the machine regularly to ensure accurate winding of the welding wire. This can be done by adjusting the tension settings, speed controls, and other parameters to achieve the desired results. It is recommended to refer to the manufacturer’s instructions for proper calibration procedures and guidelines.

In addition to regular maintenance, it is important to store the machine properly when not in use. This includes keeping it in a clean and dry environment to prevent rust and corrosion. It is also recommended to cover the machine with a protective cover or tarp to shield it from dust and debris.

Overall, proper maintenance and care of a semi-automatic welding wire precision layer winding machine are essential to ensure its longevity and optimal performance. By following these key tips, you can keep your machine in top condition and avoid costly repairs or replacements. Remember to clean, inspect, lubricate, calibrate, and store the machine properly to maximize its lifespan and efficiency.

Comparison of Different Models and Brands of Semi-Automatic Welding Wire Precision Layer Winding Machine

Semi-automatic welding wire precision layer winding machines are essential tools in the welding industry, as they help to ensure the smooth and efficient feeding of welding wire during the welding process. These machines are designed to wind welding wire onto spools with precision and accuracy, making them an indispensable piece of equipment for welders who require consistent and reliable wire feeding.

When it comes to choosing a Welding Wire Precision Layer Semi-Automatic Winding Machine, there are several factors to consider, including the model and brand of the machine. Different models and brands offer varying features and capabilities, so it is important to compare them to determine which one best suits your needs.

One popular model of semi-automatic welding wire precision layer winding machine is the XYZ-2000. This machine is known for its high-speed winding capabilities, allowing for quick and efficient spooling of welding wire. It also features a digital control panel that makes it easy to adjust the winding speed and tension, ensuring precise and consistent wire feeding.

Another model worth considering is the ABC-3000. This machine is equipped with a dual-drive system that provides superior control over the winding process, resulting in smooth and even layers of wire on the spool. It also has a built-in wire straightener that helps to prevent kinks and tangles in the wire, ensuring a seamless welding experience.

In terms of brands, there are several reputable manufacturers that produce high-quality semi-automatic welding wire precision layer winding machines. One of the most well-known brands in the industry is XYZ Welding Equipment. XYZ machines are known for their durability and reliability, making them a popular choice among welders who require a dependable machine for their welding projects.

Another reputable brand is ABC Welding Supplies. ABC machines are known for their precision and accuracy, making them a top choice for welders who require consistent and reliable wire feeding. Both XYZ and ABC offer a range of models to choose from, so you can select the one that best fits your specific needs and requirements.

When comparing different models and brands of semi-automatic welding wire precision layer winding machines, it is important to consider factors such as speed, accuracy, and durability. You should also take into account the size and weight of the machine, as well as any additional features that may be important to you.

Ultimately, the best semi-automatic welding wire precision layer winding machine for you will depend on your specific welding needs and preferences. By carefully comparing different models and brands, you can find the machine that offers the features and capabilities you require to complete your welding projects with ease and efficiency.