Table of Contents

How to Optimize Efficiency and Quality in Your Nail Making Production Line

Nail Making Machine are essential in the manufacturing industry, as nails are a common fastening material used in construction, carpentry, and various other applications. To ensure that your nail making production line operates efficiently and produces high-quality nails, it is important to optimize the process. By implementing certain strategies and best practices, you can improve the overall performance of your production line and achieve better results.

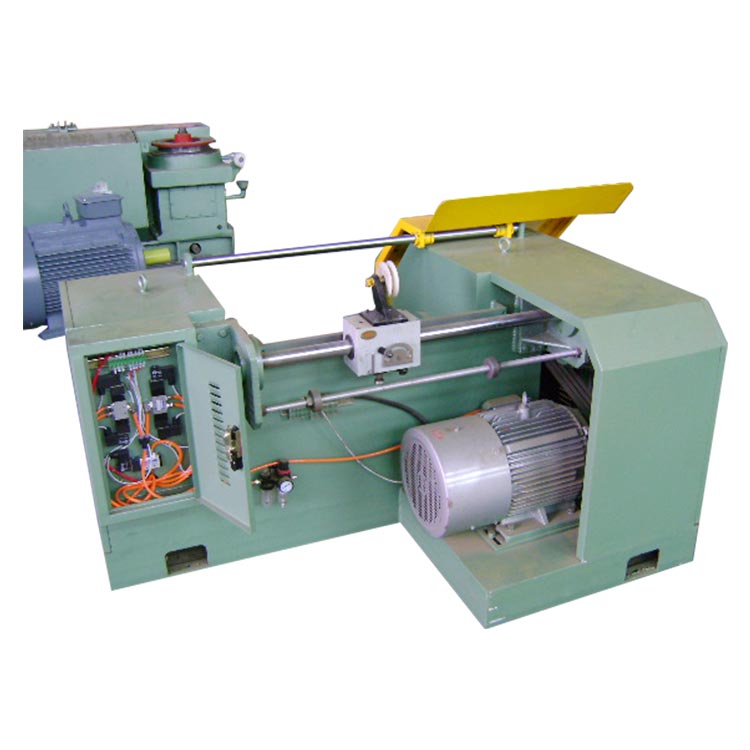

One key aspect of optimizing efficiency and quality in your nail making production line is to invest in modern and high-quality equipment. Upgrading to newer machines that are more efficient and reliable can help increase productivity and reduce downtime. Additionally, using advanced technology and automation in your production line can streamline the manufacturing process and improve the accuracy and consistency of the nails being produced.

Another important factor to consider is the maintenance of your equipment. Regular maintenance and servicing of the machines in your production line can help prevent breakdowns and ensure that they are operating at peak performance. This can also extend the lifespan of your equipment and reduce the need for costly repairs or replacements.

In addition to equipment and maintenance, optimizing the workflow and layout of your production line can also have a significant impact on efficiency and quality. By organizing the different stages of the nail making process in a logical and efficient manner, you can minimize bottlenecks and reduce the time it takes to produce each nail. This can help increase overall productivity and output without compromising on quality.

Furthermore, implementing quality control measures throughout the production process is essential for ensuring that the nails being produced meet the required standards. By conducting regular inspections and tests on the nails, you can identify any defects or issues early on and take corrective action to prevent them from affecting the final product. This can help improve the overall quality of the nails and reduce the likelihood of defects or rejects.

Training and upskilling your workforce is also crucial for optimizing efficiency and quality in your High Speed Nail Making Machine. By providing your employees with the necessary skills and knowledge to operate the equipment effectively and troubleshoot any issues that may arise, you can ensure that the production line runs smoothly and efficiently. Investing in training programs and continuous learning opportunities for your employees can help improve their performance and contribute to the overall success of your production line.

In conclusion, optimizing efficiency and quality in your nail making production line requires a combination of factors, including modern equipment, regular maintenance, efficient workflow, quality control measures, and a skilled workforce. By implementing these strategies and best practices, you can improve the performance of your production line and achieve better results in terms of productivity and product quality. Ultimately, investing in the optimization of your nail making production line can help you stay competitive in the market and meet the demands of your customers.

Benefits of Implementing a Nail Making Production Line in Your Manufacturing Process

Nail making production lines have revolutionized the manufacturing process for nails, offering numerous benefits to companies looking to streamline their operations and increase efficiency. By implementing a nail making production line, businesses can experience improved productivity, reduced labor costs, and enhanced product quality.

One of the key benefits of using a nail making production line is the significant increase in productivity that it offers. These automated systems are capable of producing nails at a much faster rate than traditional manual methods, allowing companies to meet high demand and increase their output. With a production line in place, businesses can produce a large volume of nails in a shorter amount of time, ultimately leading to increased profits and a competitive edge in the market.

In addition to improved productivity, Wire Nail Making Machine also help companies reduce labor costs. By automating the nail production process, businesses can minimize the need for manual labor and decrease the number of workers required to operate the production line. This not only saves money on labor expenses but also reduces the risk of human error, resulting in a more consistent and reliable product.

Furthermore, implementing a nail making production line can lead to enhanced product quality. These automated systems are designed to produce nails with precision and accuracy, ensuring that each nail meets the required specifications and standards. By eliminating the potential for human error, companies can produce high-quality nails that are uniform in size and shape, leading to increased customer satisfaction and loyalty.

Another benefit of using a nail making production line is the ability to customize the production process to meet specific requirements. These systems can be programmed to produce nails of various sizes, shapes, and materials, allowing companies to cater to different customer needs and preferences. Whether it’s producing standard nails for construction purposes or specialty nails for specific applications, a production line can be tailored to meet the unique demands of the market.

Additionally, nail making production lines offer improved safety and efficiency in the manufacturing process. By automating the production of nails, companies can reduce the risk of workplace accidents and injuries associated with manual labor. These systems are equipped with safety features and protocols to ensure the well-being of workers and maintain a safe working environment.

Overall, implementing a nail making production line in your manufacturing process can bring numerous benefits to your business. From increased productivity and reduced labor costs to enhanced product quality and customization capabilities, these automated systems offer a competitive advantage in the market. By investing in a nail making production line, companies can streamline their operations, improve efficiency, and ultimately achieve greater success in the industry.