Table of Contents

Benefits of Using Nail Making Machines Automatic

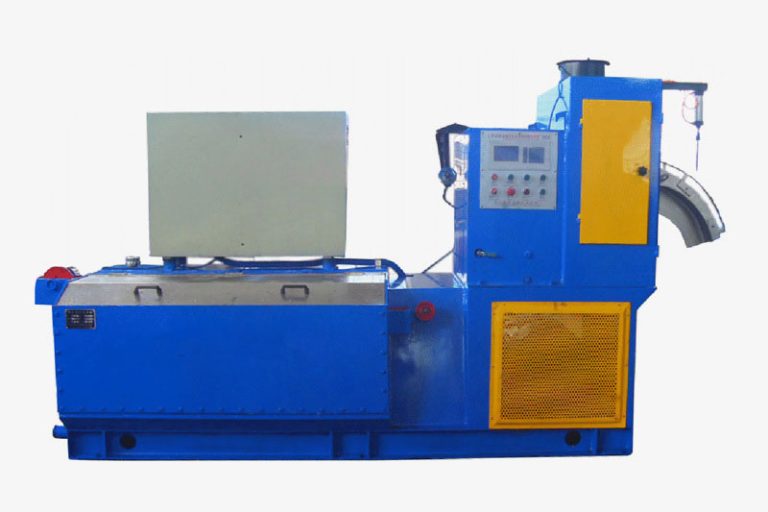

Nail making machine have revolutionized the way nails are produced in the construction industry. These machines have made the process of nail manufacturing faster, more efficient, and cost-effective. One of the most popular types of nail making machines is the automatic nail making machine. In this article, we will discuss the benefits of using an automatic nail making machine.

One of the primary benefits of using an automatic nail making machine is the speed at which nails can be produced. These machines are capable of producing thousands of nails per minute, significantly increasing the production capacity of a nail manufacturing plant. This increased speed not only allows manufacturers to meet the demands of their customers more efficiently but also helps reduce production costs.

In addition to speed, automatic nail making machines also offer a high level of precision in nail production. These machines are equipped with advanced technology that ensures each nail is produced to the exact specifications required. This precision is essential in industries where nails are used for critical applications, such as in the construction of buildings or bridges.

Another benefit of using an automatic nail making machine is the reduction in labor costs. These machines require minimal human intervention, as they are fully automated and can operate continuously for long periods. This means that manufacturers can reduce the number of workers needed to operate the machine, leading to significant cost savings in the long run.

Furthermore, automatic Wire Nail Making Machine are designed to be energy-efficient, helping manufacturers reduce their overall energy consumption. These machines are equipped with energy-saving features that help minimize electricity usage without compromising on production efficiency. This not only helps reduce operating costs but also contributes to a more sustainable manufacturing process.

Automatic nail making machines are also known for their durability and reliability. These machines are built to withstand the rigors of continuous operation, ensuring that they can perform reliably for extended periods without the need for frequent maintenance or repairs. This reliability is crucial for manufacturers who rely on their nail making machines to meet production deadlines and maintain a consistent level of quality.

Additionally, automatic nail making machines offer versatility in nail production. These machines can be easily adjusted to produce nails of different sizes and specifications, allowing manufacturers to cater to a wide range of customer requirements. This flexibility is essential in industries where nails are used for various applications, as it allows manufacturers to adapt quickly to changing market demands.

In conclusion, the benefits of using an automatic nail making machine are numerous and significant. From increased production speed and precision to reduced labor costs and energy efficiency, these machines offer a range of advantages that can help manufacturers improve their manufacturing processes and stay competitive in the market. With their durability, reliability, and versatility, automatic nail making machines are an essential tool for any nail manufacturing plant looking to streamline their production process and enhance their overall efficiency.

How to Choose the Right Nail Making Machine Automatic for Your Business

Nail making machine have revolutionized the way nails are produced in the construction industry. With the advancement of technology, nail making machines have become more efficient, faster, and easier to use. One of the most popular types of nail making machines is the automatic nail making machine. These machines are designed to produce nails in large quantities with minimal human intervention, making them ideal for businesses looking to increase their production capacity.

When choosing the right nail making machine automatic for your business, there are several factors to consider. The first thing to consider is the production capacity of the machine. Automatic nail making machines come in various sizes and can produce different quantities of nails per minute. It is important to choose a machine that can meet the production demands of your business. If you have a high production volume, you will need a machine that can produce nails quickly and efficiently.

Another important factor to consider is the size and type of nails that the machine can produce. Automatic nail making machines come in different configurations and can produce various types of nails, such as common nails, coil nails, and roofing nails. It is important to choose a machine that can produce the type and size of nails that are required for your business. Consider the specifications of the machine, such as the nail length, diameter, and material compatibility.

The quality of the nails produced by the machine is also an important consideration. Look for a machine that is made of high-quality materials and has a robust construction. This will ensure that the machine is durable and can withstand the rigors of continuous use. Additionally, consider the precision and accuracy of the machine in producing nails. A machine that can produce nails with consistent quality will help maintain the reputation of your business and satisfy your customers.

Ease of use and maintenance are also important factors to consider when choosing a nail making machine automatic. Look for a machine that is user-friendly and easy to operate. Consider the features of the machine, such as automatic feeding, cutting, and stacking mechanisms, which can help streamline the production process. Additionally, choose a machine that is easy to maintain and has readily available spare parts. This will help minimize downtime and ensure that the machine operates efficiently.

Cost is another important factor to consider when choosing a nail making machine automatic for your business. Compare the prices of different machines and consider the overall value that each machine offers. Look for a machine that offers a good balance between price and performance. Consider the long-term costs of operating the machine, such as energy consumption, maintenance, and repair costs.

In conclusion, choosing the right nail making machine automatic for your business requires careful consideration of several factors. Consider the production capacity, nail type and size, quality of nails produced, ease of use and maintenance, and cost of the machine. By choosing a machine that meets your production needs and offers good value for money, you can increase the efficiency and productivity of your business.

Maintenance Tips for Nail Making Machine Automatic

High Speed Nail Making Machine have revolutionized the nail manufacturing industry by automating the process of nail production. These machines are efficient, fast, and reliable, making them a popular choice for nail manufacturers worldwide. However, like any other machine, nail making machines require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tips for nail making machines is to keep them clean. Dust, debris, and metal shavings can accumulate in the machine over time, causing it to malfunction or break down. Regularly cleaning the machine with a soft brush and compressed air can help prevent these issues and keep the machine running smoothly.

In addition to keeping the machine clean, it is also important to lubricate the moving parts regularly. Lubrication helps reduce friction between the parts, preventing wear and tear and extending the life of the machine. Be sure to use the recommended lubricant for your specific nail making machine and follow the manufacturer’s instructions for proper lubrication.

Another maintenance tip for nail making machines is to inspect the machine regularly for any signs of wear or damage. Check the belts, gears, and other components for any signs of wear, such as cracks, fraying, or corrosion. Replace any worn or damaged parts immediately to prevent further damage to the machine.

It is also important to calibrate the machine regularly to ensure accurate nail production. Over time, the machine’s settings may drift, leading to inconsistencies in nail size and quality. Calibrating the machine according to the manufacturer’s specifications can help maintain consistent nail production and prevent costly errors.

Regularly checking the machine’s electrical components is another important maintenance tip for nail making machines. Loose connections, damaged wires, or faulty sensors can cause the machine to malfunction or stop working altogether. Inspect the electrical components regularly and replace any damaged parts to keep the machine running smoothly.

Lastly, it is important to train your operators on proper machine maintenance and operation. Educate them on the importance of regular maintenance, how to clean and lubricate the machine, and how to identify and address common issues. By empowering your operators with the knowledge and skills to maintain the machine properly, you can prevent costly downtime and ensure the longevity of your nail making machine.

In conclusion, regular maintenance is essential for keeping your nail making machine automatic running smoothly and efficiently. By following these maintenance tips, you can prevent costly breakdowns, extend the life of your machine, and ensure consistent nail production. Remember to keep the machine clean, lubricate the moving parts, inspect for wear and damage, calibrate the machine regularly, check the electrical components, and train your operators on proper maintenance procedures. With proper care and maintenance, your nail making machine automatic can continue to produce high-quality nails for years to come.