Maintenance of Using Multiple Drawing Machine in your industry

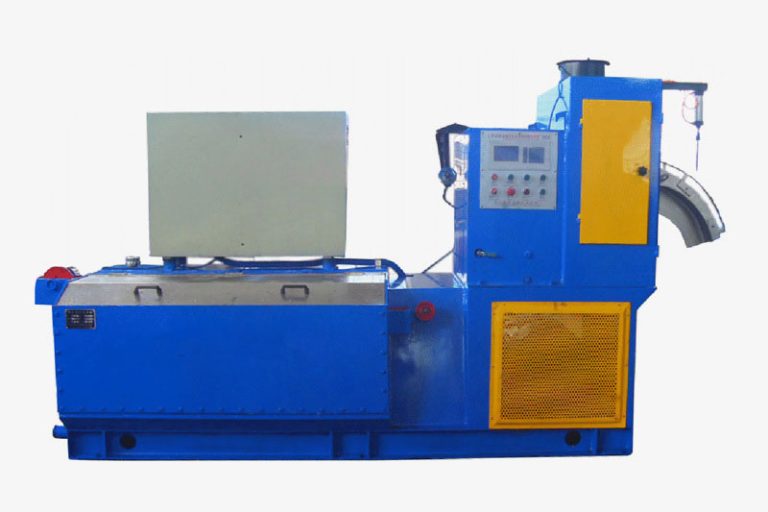

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. While single Wire Drawing Machines are commonly used in the industry, there are several advantages to using multiple wire drawing machines in a production line.

One of the main advantages of using multiple wire drawing machines is increased production capacity. By having several machines operating simultaneously, manufacturers can significantly increase the output of their production line. This is particularly beneficial for companies that have high demand for their products and need to meet tight deadlines. With multiple machines in operation, manufacturers can produce more wire in a shorter amount of time, allowing them to fulfill orders quickly and efficiently.

Another advantage of using multiple wire drawing machines is improved efficiency. When one machine is used to draw wire, there is a limit to how much wire can be processed at a time. By using multiple machines, manufacturers can distribute the workload evenly across the machines, reducing the risk of overloading any one machine. This helps to prevent downtime and ensures that the production line runs smoothly and efficiently.

In addition to increased production capacity and improved efficiency, using multidrafts wire drawing machine can also lead to cost savings for manufacturers. While the initial investment in multiple machines may be higher than that of a single machine, the long-term cost savings can be significant. By increasing production capacity and efficiency, manufacturers can reduce their overall production costs and increase their profit margins.

Furthermore, using multiple wire drawing machines can also improve the quality of the wire produced. When one machine is used to draw wire, there is a risk of inconsistencies in the diameter and quality of the wire. By using multiple machines, manufacturers can ensure that each wire is drawn to the exact specifications required, resulting in a higher quality end product. This is particularly important for industries that require precise wire measurements, such as the electronics industry.

Overall, the advantages of using multiple wire drawing machines in a production line are clear. Increased production capacity, improved efficiency, cost savings, and higher quality products are just a few of the benefits that manufacturers can enjoy by incorporating multiple machines into their production process. By investing in multiple wire drawing machines, manufacturers can streamline their production line, increase their output, and ultimately improve their bottom line.