Table of Contents

How to Properly Maintain and Troubleshoot Multidrafts Wire Drawing Machine

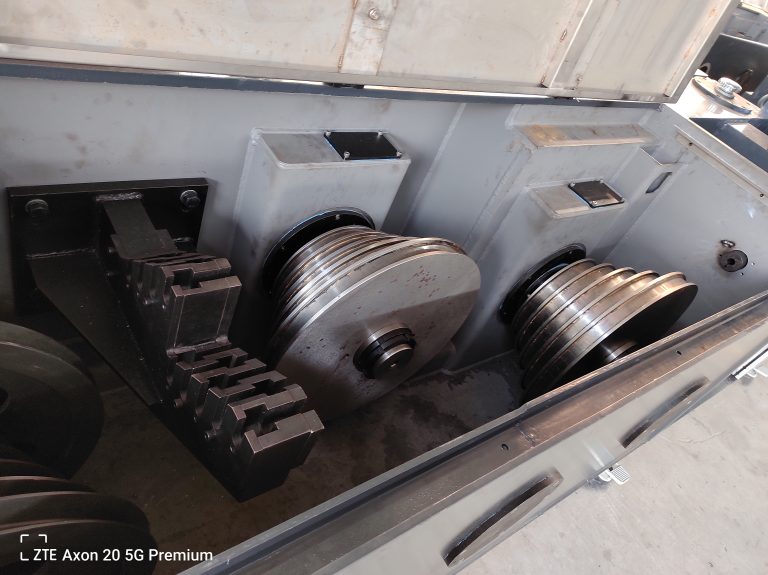

Multidrafts wire drawing machines are essential tools in the manufacturing industry for producing wire of various diameters and materials. These machines are designed to pull wire through a series of dies to reduce its diameter and improve its quality. Proper maintenance and troubleshooting of multidrafts wire drawing machines are crucial to ensure their optimal performance and longevity.

Regular maintenance of Straight Line Wire Drawing Machine is essential to prevent breakdowns and ensure smooth operation. One of the most important maintenance tasks is to regularly lubricate the machine’s moving parts to reduce friction and wear. This can help prevent overheating and premature failure of components. It is also important to regularly inspect the machine for any signs of wear or damage, such as worn-out dies or broken belts. These issues should be addressed promptly to prevent further damage to the machine.

In addition to regular maintenance, proper troubleshooting of multidrafts wire drawing machines is essential to identify and address any issues that may arise during operation. One common issue that may occur is uneven wire drawing, which can result in wire with inconsistent diameter. This can be caused by misalignment of the dies or improper tension on the wire. To troubleshoot this issue, the dies should be checked for alignment and adjusted if necessary. The tension on the wire should also be adjusted to ensure smooth and consistent drawing.

Another common issue that may occur with multidrafts wire drawing machines is overheating. This can be caused by a variety of factors, such as excessive friction or inadequate lubrication. To troubleshoot this issue, the machine should be inspected for any signs of overheating, such as smoking or burning smells. The lubrication system should also be checked to ensure that all moving parts are properly lubricated. If overheating persists, it may be necessary to reduce the drawing speed or increase the cooling capacity of the machine.

Proper maintenance and troubleshooting of multidrafts wire drawing machines require a thorough understanding of the machine’s components and operation. It is important to follow the manufacturer’s guidelines for maintenance and troubleshooting to ensure the machine’s optimal performance. Regular training of operators on proper maintenance procedures can also help prevent issues and prolong the machine’s lifespan.

In conclusion, multidrafts wire drawing machines are essential tools in the manufacturing industry for producing high-quality wire. Proper maintenance and troubleshooting of these machines are crucial to ensure their optimal performance and longevity. By following the manufacturer’s guidelines for maintenance and troubleshooting, operators can prevent breakdowns and address issues promptly to keep the machine running smoothly. With regular maintenance and proper troubleshooting, multidrafts wire drawing machines can continue to produce high-quality wire for years to come.

Advantages of Using Multidrafts Wire Drawing Machines in Industrial Applications

Wire drawing is a process used in various industries to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of different sizes and shapes that are used in a wide range of applications, from electrical wiring to construction materials. One of the key components in the wire drawing process is the wire drawing machine, which is responsible for pulling the wire through the dies to achieve the desired diameter.

One type of contineous wire drawing machine that has gained popularity in recent years is the multidrafts wire drawing machine. This type of machine is designed to provide multiple drafts or passes through the dies, which results in a more uniform and consistent reduction in wire diameter. There are several advantages to using multidrafts wire drawing machines in industrial applications.

One of the main advantages of multidrafts wire drawing machines is their ability to produce wires with a high level of precision and accuracy. By providing multiple drafts through the dies, these machines can ensure that the wire is reduced to the desired diameter with minimal variation. This is crucial in industries where precision is key, such as the automotive or aerospace industries, where even the slightest deviation in wire diameter can lead to product failure.

Another advantage of multidrafts wire drawing machines is their ability to increase productivity and efficiency in the wire drawing process. By providing multiple drafts, these machines can reduce the number of passes required to achieve the desired wire diameter, saving time and energy. This can result in significant cost savings for manufacturers, as fewer passes mean less wear and tear on the dies and other components of the machine.

In addition to precision and efficiency, multidrafts wire drawing machines also offer improved control over the wire drawing process. These machines are equipped with advanced control systems that allow operators to adjust parameters such as speed, tension, and draft ratio to achieve the desired results. This level of control is essential in industries where consistency and quality are paramount, as it allows manufacturers to produce wires that meet strict specifications and standards.

Furthermore, multidrafts wire drawing machines are versatile and can be used to produce wires of different materials and sizes. Whether you are working with steel, aluminum, copper, or any other material, these machines can be easily adjusted to accommodate the specific requirements of the material being drawn. This flexibility makes multidrafts wire drawing machines a valuable asset for manufacturers who need to produce a wide range of wire products.

Overall, multidrafts wire drawing machines offer a range of advantages that make them an ideal choice for industrial applications. From precision and efficiency to control and versatility, these machines can help manufacturers produce high-quality wires that meet the demands of today’s industries. If you are looking to improve your wire drawing process, consider investing in a multidrafts wire drawing machine to take your production to the next level.