Advantages of Using Multidrafts Wire Drawing Machine

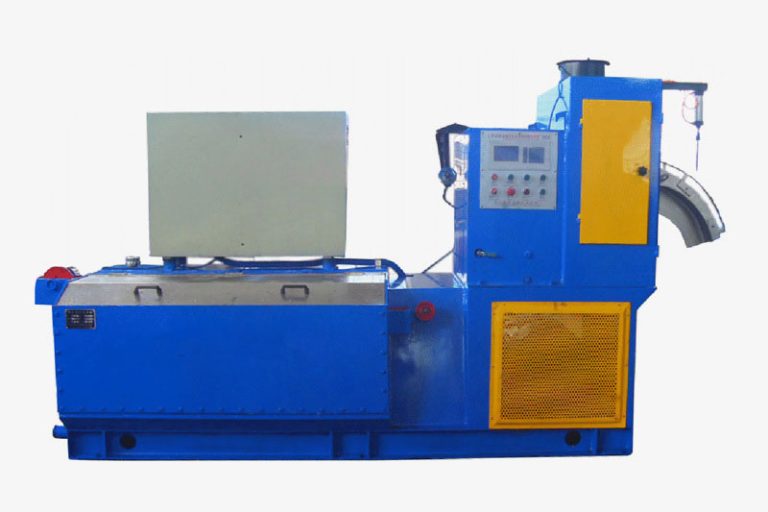

Dry Type Wire Drawing Machine is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One of the key tools used in wire drawing is the wire drawing machine, which helps to automate and streamline the process.

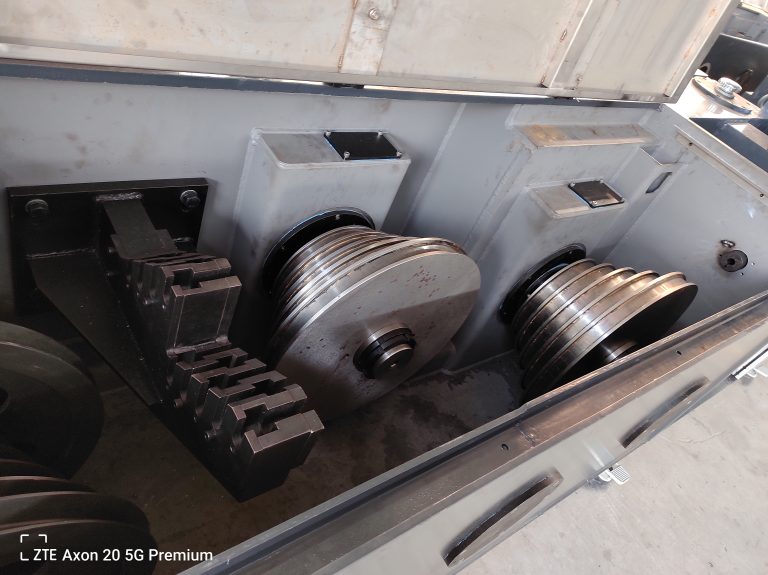

One type of wire drawing machine that has gained popularity in recent years is the multidrafts wire drawing machine. This machine is designed to draw wire through multiple drafts, or stages, in order to achieve a more precise and consistent reduction in diameter. There are several advantages to using a multidrafts wire drawing machine, which we will explore in this article.

One of the main advantages of using a multidrafts wire drawing machine is the ability to achieve a higher degree of precision in the wire drawing process. By passing the wire through multiple drafts, the machine is able to gradually reduce the diameter of the wire in a controlled manner, resulting in a more uniform and consistent final product. This is particularly important for applications where precision is critical, such as in the production of medical devices or aerospace components.

In addition to precision, contineous wire drawing machine also offer increased flexibility in terms of the types of wire that can be processed. These machines are capable of drawing a wide range of wire sizes and materials, making them suitable for a variety of applications. Whether you are working with copper, aluminum, steel, or other materials, a multidrafts wire drawing machine can be adjusted to meet your specific requirements.

Another advantage of using a multidrafts wire drawing machine is the ability to achieve higher production speeds. By passing the wire through multiple drafts simultaneously, these machines are able to draw wire at a faster rate than traditional single-draft machines. This can help to increase productivity and reduce production times, making multidrafts wire drawing machines a cost-effective solution for manufacturers looking to streamline their operations.

Furthermore, multidrafts wire drawing machines are also known for their durability and reliability. These machines are built to withstand the rigors of continuous operation, making them a long-lasting investment for manufacturers. With proper maintenance and care, a multidrafts wire drawing machine can provide years of reliable service, helping to minimize downtime and maximize productivity.

In conclusion, the advantages of using a multidrafts wire drawing machine are clear. From increased precision and flexibility to higher production speeds and durability, these machines offer a range of benefits for manufacturers looking to improve their wire drawing processes. Whether you are producing wires for electrical applications, construction projects, or any other industry, a multidrafts wire drawing machine can help you achieve the results you need.