Table of Contents

Benefits of Using Multidrafts Wire Drawing Machine in Industrial Applications

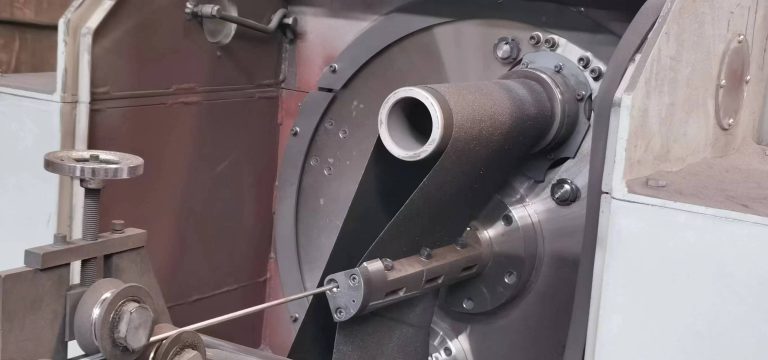

Wire drawing machine is a process used in various industries to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of different sizes and shapes that are used in a wide range of applications, from electrical wiring to construction materials. One of the key machines used in wire drawing is the multidrafts wire drawing machine, which offers several benefits for industrial applications.

One of the main advantages of using a multidrafts wire drawing machine is its ability to produce wires with consistent diameter and surface finish. This is crucial for ensuring the quality and performance of the final product, as any variations in diameter or surface finish can affect the wire’s strength, conductivity, and other properties. The multidrafts design of the machine allows for multiple drafts or passes of the wire through the dies, which helps to achieve a more uniform reduction in diameter and smoother surface finish.

In addition to producing high-quality wires, multidrafts wire drawing machines are also known for their high efficiency and productivity. These machines are designed to operate at high speeds and can process large volumes of wire in a relatively short amount of time. This makes them ideal for industrial applications where large quantities of wire need to be produced quickly and efficiently. The multidrafts design also allows for greater control over the wire drawing process, enabling operators to adjust the speed, tension, and other parameters to achieve the desired results.

Another benefit of using a multidrafts wire drawing machine is its versatility and flexibility. These machines can be used to draw wires of different materials, sizes, and shapes, making them suitable for a wide range of applications. Whether you need to produce thin copper wires for electrical applications or thick steel wires for construction purposes, a multidrafts wire drawing machine can handle the job with ease. This versatility makes these machines a valuable asset for industries that require a variety of wire products.

Furthermore, multidrafts wire drawing machines are known for their durability and reliability. These machines are built to withstand the rigors of industrial production and are designed to operate continuously for long periods without experiencing breakdowns or malfunctions. This reliability is essential for ensuring uninterrupted production and minimizing downtime, which can be costly for industrial operations. With proper maintenance and care, a multidrafts wire drawing machine can provide years of reliable service, making it a sound investment for any industrial application.

In conclusion, the multidrafts wire drawing machine offers several benefits for industrial applications, including high-quality wire production, efficiency, versatility, and reliability. These machines are essential for industries that require precise and consistent wire products, and their ability to handle a wide range of materials and sizes makes them a valuable asset for any production facility. If you are looking to improve your wire drawing process and enhance the quality of your wire products, consider investing in a multidrafts wire drawing machine.

How to Properly Maintain and Troubleshoot Multidrafts Wire Drawing Machine

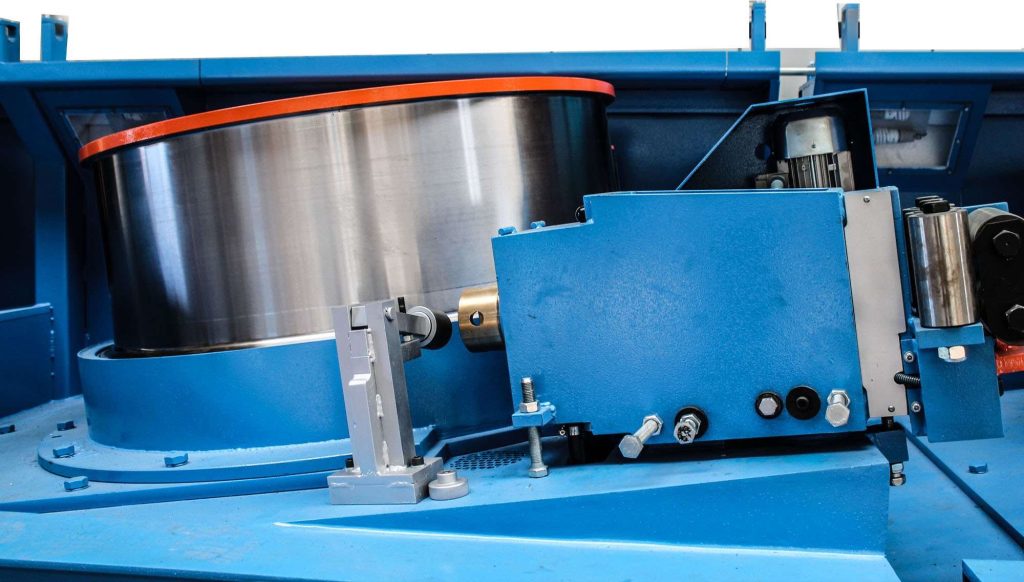

Wire drawing machines are essential tools in the manufacturing industry, used to produce wires of various diameters and lengths. One popular type of wire drawing machine is the Multidrafts Wire Drawing Machine, known for its efficiency and reliability. Proper maintenance and troubleshooting of this machine are crucial to ensure smooth operation and prevent costly downtime. In this article, we will discuss some key maintenance tips and common troubleshooting techniques for the Multidrafts Wire Drawing Machine.

Regular maintenance is essential to keep the Dry Type Wire Drawing Machine in optimal condition. One of the most important maintenance tasks is to regularly lubricate the machine’s moving parts. This helps reduce friction and wear, prolonging the machine’s lifespan. It is recommended to use high-quality lubricants that are suitable for the specific components of the machine.

In addition to lubrication, it is important to regularly inspect the machine for any signs of wear or damage. Check the wire drawing dies, rollers, and other components for any signs of wear and tear. Replace any worn-out parts immediately to prevent further damage to the machine. Regular cleaning of the machine is also important to remove any dirt or debris that may affect its performance.

Another important aspect of maintenance is to regularly check the tension of the wire being drawn. Improper tension can lead to uneven wire drawing and poor quality output. Adjust the tension settings as needed to ensure smooth and consistent wire drawing.

Despite regular maintenance, issues may still arise with the Multidrafts Wire Drawing Machine. It is important to be able to troubleshoot these issues quickly to minimize downtime. One common issue is wire breakage during the drawing process. This can be caused by various factors, such as improper tension, worn-out dies, or a misaligned machine. Check the tension settings, inspect the dies, and ensure that the machine is properly aligned to prevent wire breakage.

Another common issue is overheating of the machine. This can be caused by a lack of lubrication, worn-out components, or excessive friction. If the machine is overheating, stop the operation immediately and allow it to cool down. Inspect the machine for any signs of wear or damage, and lubricate the moving parts as needed.

In some cases, the wire drawing machine may produce wires of inconsistent diameter. This can be caused by uneven tension, worn-out dies, or misalignment of the machine. Adjust the tension settings, inspect the dies, and ensure that the machine is properly aligned to produce wires of consistent diameter.

In conclusion, proper maintenance and troubleshooting are essential for the efficient operation of the Multidrafts Wire Drawing Machine. Regular lubrication, inspection, and cleaning are key maintenance tasks to keep the machine in optimal condition. In case of issues such as wire breakage, overheating, or inconsistent wire diameter, it is important to troubleshoot the machine quickly to prevent costly downtime. By following these maintenance tips and troubleshooting techniques, you can ensure the smooth operation of your Multidrafts Wire Drawing Machine and produce high-quality wires for your manufacturing needs.