Exploring the merits of Using a Mechanical Sand Belt Descaling Machine

In industrial settings where metal surfaces need to be prepared for subsequent processes like painting, coating, or welding, the effectiveness of surface preparation equipment is crucial. One such essential tool is the Mechanical Sand Belt Descaling Machine, which offers significant advantages over traditional methods.

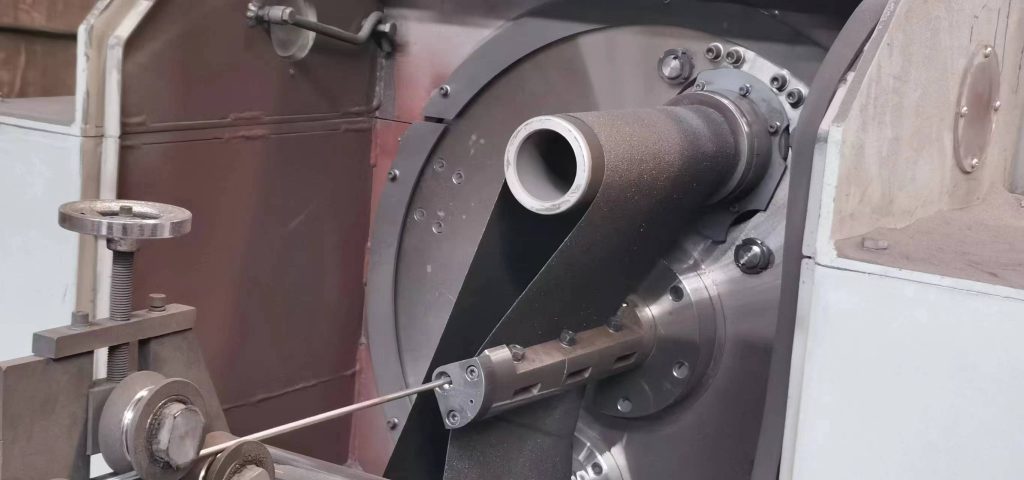

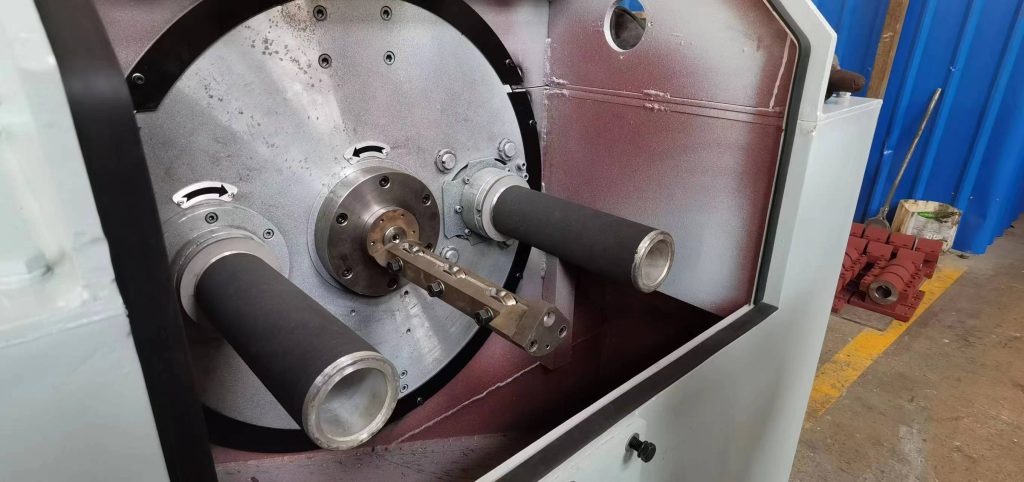

Traditionally, descaling involved labor-intensive processes such as manual grinding or chemical treatment, which were time-consuming and often inconsistent in achieving desired surface profiles. The advent of mechanical sand belt descaling machines revolutionized this process by providing a more efficient and precise method. These machines are equipped with abrasive belts that can swiftly remove scales, rust, and contaminants from metal surfaces, ensuring a clean and uniform finish.

The primary benefit of using a Mechanical Sand Belt Descaling Machine lies in its efficiency. Unlike manual methods that require significant manpower and time, these machines operate swiftly, enhancing productivity and reducing labor costs. They are capable of covering large surface areas quickly, making them suitable for high-volume production environments where time is of the essence.

Moreover, consistency in surface preparation is critical for ensuring the quality and integrity of subsequent processes. Mechanical Sanding Belt Grinding Descaler machines deliver uniform results across all treated surfaces, eliminating variations that might occur with manual techniques. This consistency not only enhances the aesthetic appeal of finished products but also improves the adhesion of coatings and paints, thereby prolonging the lifespan of the treated materials.

Another notable advantage is the versatility of these machines. They can be adjusted to accommodate different types of metals and surface conditions, from light cleaning to heavy-duty descaling. This adaptability makes them indispensable in industries ranging from automotive manufacturing to shipbuilding, where various metal components require precise surface preparation tailored to their specific applications.

Furthermore, the safety features integrated into modern Mechanical Sand Belt Descaling Machines contribute to a safer working environment. These machines are designed with protective guards and automatic shut-off mechanisms to minimize the risk of accidents and ensure operator safety. This focus on safety not only protects personnel but also reduces downtime due to injuries or equipment damage.

In terms of operational costs, mechanical descaling machines are cost-effective investments over the long term. While initial procurement costs may be higher compared to manual tools, the savings in labor, time, and maintenance expenses justify the investment. They also contribute to overall operational efficiency by streamlining production processes and reducing the reliance on multiple stages of surface preparation.

Finally, the environmental impact of using mechanical sand belt machines is relatively lower compared to chemical treatments. They produce less waste and do not involve hazardous chemicals, aligning with modern sustainability standards in manufacturing practices.

In conclusion, the benefits of employing a Mechanical Sand Belt Descaling Machine are manifold: increased efficiency, enhanced surface quality, operational versatility, improved safety, and cost-effectiveness. These machines represent a significant advancement in industrial surface preparation technology, catering to the evolving needs of modern manufacturing and ensuring consistent, high-quality results across various metalworking applications. As industries continue to prioritize efficiency and quality, mechanical descaling machines remain indispensable tools for achieving optimal surface preparation standards.