Table of Contents

How to Properly Maintain and Troubleshoot a Mechanical Sand Belt Descaling Machine

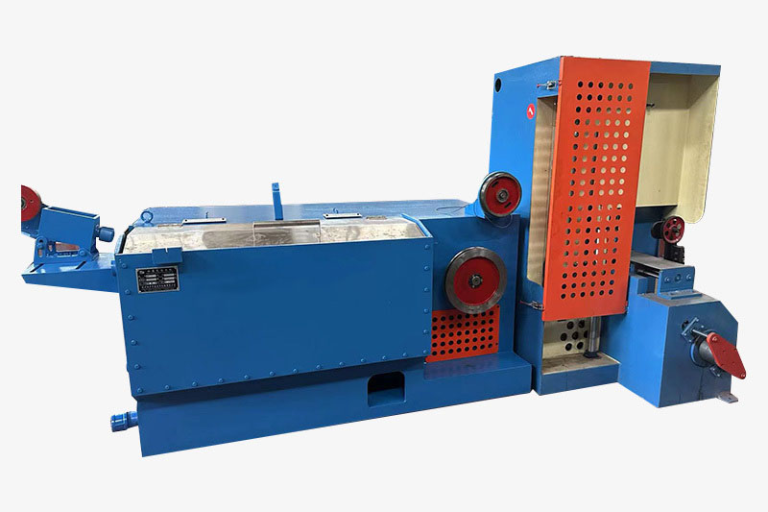

A mechanical sand belt descaling machine is a crucial piece of equipment in various industries, including metal fabrication, automotive, and aerospace. This machine is used to remove scale, rust, and other surface contaminants from metal parts, ensuring a clean and smooth surface for further processing or finishing. Proper maintenance and troubleshooting of a mechanical sand belt descaling machine are essential to ensure its optimal performance and longevity.

Regular maintenance of a mechanical sand belt descaling machine is key to preventing breakdowns and ensuring consistent operation. One of the most important maintenance tasks is to regularly inspect and replace the sand belts. Over time, the sand belts can become worn or damaged, leading to poor descaling performance and potential damage to the metal parts. It is recommended to replace the sand belts according to the manufacturer’s guidelines or whenever signs of wear or damage are observed.

In addition to replacing the sand belts, it is also important to regularly clean and lubricate the machine’s moving parts. Dust, debris, and metal shavings can accumulate in the machine, causing friction and wear on the components. Regular cleaning with compressed air or a vacuum can help prevent buildup and ensure smooth operation. Lubricating the machine’s moving parts with a suitable lubricant will also help reduce friction and extend the life of the machine.

Another important maintenance task is to regularly check and adjust the tension of the sand belts. Proper tension is essential for effective descaling and preventing slippage or damage to the belts. The tension should be adjusted according to the manufacturer’s guidelines or whenever the belts appear loose or tight. It is also important to check the alignment of the sand belts to ensure they are running straight and true. Misaligned belts can cause uneven descaling and premature wear on the machine.

In addition to regular maintenance, troubleshooting is also an important aspect of maintaining a mechanical sand belt descaling machine. When the machine is not operating properly, it is important to identify and address the issue promptly to prevent further damage or downtime. Common issues that may arise include uneven descaling, excessive noise, or belt slippage.

When troubleshooting a mechanical wire descaling blt grinding machine, it is important to start by checking the sand belts for wear or damage. Uneven descaling or poor performance can often be attributed to worn or damaged belts. If the belts are in good condition, the next step is to check the tension and alignment of the belts. Adjusting the tension or realigning the belts may help resolve the issue.

If the machine is making excessive noise, it is important to check for loose or damaged components. Loose bolts, worn bearings, or misaligned parts can all contribute to noise issues. Tightening or replacing the affected components may help reduce noise and improve the machine’s performance.

In the case of belt slippage, it is important to check the tension and alignment of the belts. If the belts are properly tensioned and aligned, the issue may be due to worn or damaged pulleys. Replacing the pulleys or adjusting the belt tracking may help resolve the problem.

In conclusion, proper maintenance and troubleshooting are essential for ensuring the optimal performance and longevity of a mechanical sand belt descaling machine. By following the manufacturer’s guidelines for maintenance and promptly addressing any issues that arise, you can keep your machine running smoothly and efficiently for years to come.

Benefits of Using a Mechanical Sand Belt Descaling Machine in Industrial Applications

In industrial applications where metal surfaces need to be cleaned and prepared for further processing, a mechanical sand belt descaling machine is a valuable tool. This machine uses abrasive belts to remove scale, rust, and other surface contaminants from metal parts, leaving them clean and ready for the next stage of production. There are several benefits to using a mechanical sand belt descaling machine in industrial settings.

One of the main advantages of using a mechanical sand belt descaling machine is its efficiency. These machines are designed to quickly and effectively remove surface contaminants from metal parts, saving time and labor compared to manual descaling methods. With a mechanical sand belt descaling machine, large quantities of metal parts can be processed in a relatively short amount of time, increasing productivity and reducing production costs.

Another benefit of using a mechanical sand belt descaling machine is its consistency. Manual descaling methods can result in uneven cleaning and surface preparation, leading to quality control issues and potential rework. In contrast, a mechanical sand belt descaling machine provides consistent results, ensuring that all metal parts are cleaned to the same high standard. This consistency helps to improve product quality and reduce the risk of defects in finished products.

In addition to efficiency and consistency, a mechanical sand belt descaling machine offers versatility in terms of the types of metal parts it can process. These machines can be used to clean a wide range of metal surfaces, from flat sheets to complex shapes and contours. This versatility makes mechanical sand belt descaling machines suitable for a variety of industrial applications, from automotive manufacturing to aerospace engineering.

Furthermore, using a mechanical sand belt descaling machine can help to extend the lifespan of metal parts. By removing surface contaminants such as scale and rust, these machines can prevent corrosion and other forms of degradation that can compromise the integrity of metal parts over time. This can result in longer-lasting products that require less maintenance and repair, saving time and money in the long run.

Overall, the benefits of using a mechanical sand belt descaling machine in industrial applications are clear. From increased efficiency and consistency to versatility and improved product quality, these machines offer a range of advantages that can help to streamline production processes and enhance the performance of metal parts. Whether you are in the automotive, aerospace, or any other industry that relies on clean and prepared metal surfaces, a mechanical sand belt descaling machine is a valuable investment that can deliver significant returns.