용접전극 자동교정 및 절단기의 장점 탐구

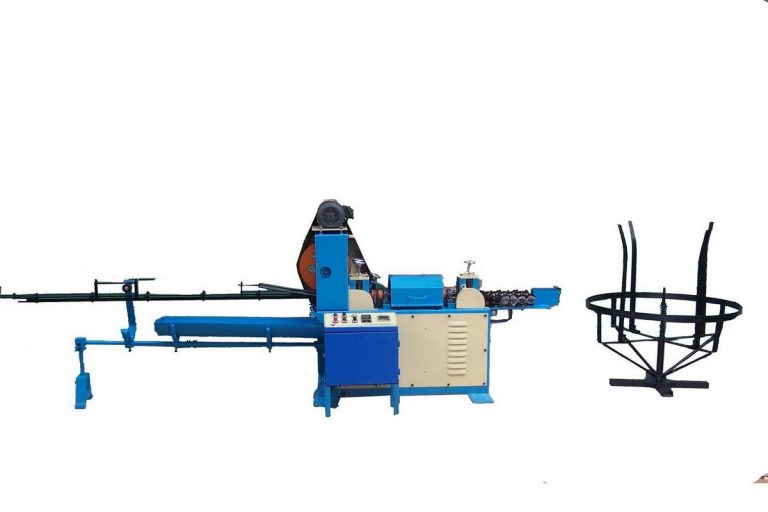

자동 용접전극 교정 및 절단기 보다 효율적이고 정확한 용접 전극 생산 방법을 제공하여 용접 산업에 혁명을 일으켰습니다. 이 기계는 모든 용접 작업에 대한 귀중한 투자가 될 수 있는 다양한 이점을 제공합니다.

자동 교정 및 절단 기계 사용의 주요 이점 중 하나는 생산성이 향상된다는 것입니다. 이 기계는 수동 방법보다 훨씬 빠른 속도로 전극을 직선화하고 절단할 수 있어 생산량을 늘리고 처리 시간을 단축할 수 있습니다. 이는 용접 작업이 촉박한 마감 기한을 지키고 전반적인 효율성을 높이는 데 도움이 될 수 있습니다.

생산성 향상 외에도 자동 교정 및 절단 기계는 향상된 정확성과 일관성을 제공합니다. 전극을 교정하고 절단하는 수동 방법은 사람의 실수로 인해 길이가 고르지 않고 품질이 일관되지 않을 수 있습니다. 반면에 자동 기계는 전극을 높은 정확도로 정확한 길이로 절단하도록 프로그래밍되어 있어 각 전극이 동일한 품질 표준을 충족하도록 보장합니다.

사용의 또 다른 이점 와이어 교정 및 절단기 쓰레기 줄이기

게다가 자동 교정 및 절단 기계는 전극을 수동으로 취급할 때 발생할 수 있는 부상 위험을 줄여 작업장 안전을 향상시키는 데 도움이 될 수 있습니다. 이 기계는 사람의 개입을 최소화하면서 작동하도록 설계되어 작업자가 날카롭거나 뜨거운 전극을 다룰 필요성을 줄입니다. 이는 보다 안전한 작업 환경을 조성하고 작업 현장에서 사고 위험을 줄이는 데 도움이 될 수 있습니다.

이러한 이점 외에도 자동 교정 및 절단 기계는 높은 수준의 다양성을 제공합니다. 이 기계는 다양한 전극 크기와 재료를 처리할 수 있어 다양한 용접 응용 분야에 적합합니다. 연강, 스테인리스강 또는 알루미늄 전극을 사용하여 작업하는 경우 자동 기계를 프로그래밍하여 전극을 정밀하게 절단하고 펴도록 할 수 있습니다.

전반적으로 용접봉 자동 교정 및 절단기를 사용하면 얻을 수 있는 이점은 분명합니다. 이 기계는 향상된 생산성, 향상된 정확성과 일관성, 폐기물 감소, 향상된 작업장 안전 및 다양성을 제공하므로 모든 용접 작업에 대한 귀중한 투자가 됩니다. 용접 공정에 자동 기계를 통합하면 생산을 간소화하고 품질을 향상하며 직원을 위한 보다 안전한 작업 환경을 조성할 수 있습니다.