Table of Contents

Tips Perawatan untuk Memastikan Kinerja Optimal Mesin Penggulung Lapisan Presisi

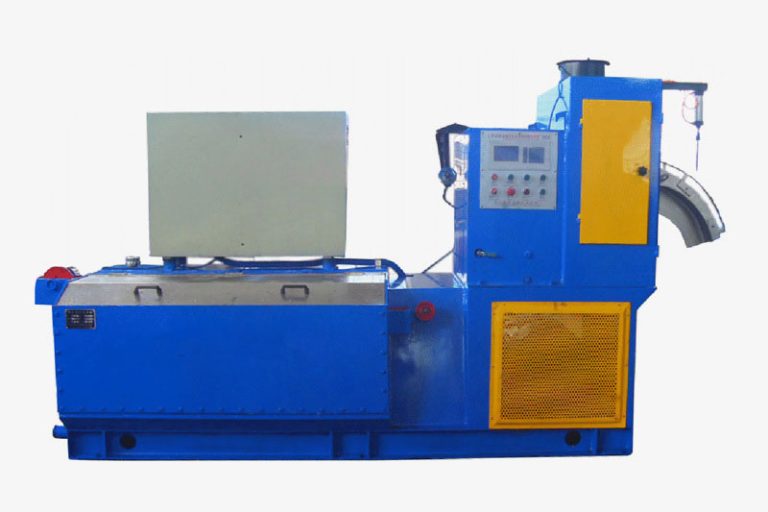

Mesin penggulung lapisan presisi adalah peralatan penting dalam industri manufaktur, digunakan untuk menggulung bahan seperti kawat, kabel, dan pipa ke gulungan atau gulungan dengan presisi dan akurasi. Mesin-mesin ini dirancang untuk menangani berbagai macam bahan dan dapat disesuaikan untuk memenuhi kebutuhan produksi tertentu. Untuk memastikan kinerja optimal dan umur panjang mesin penggulung lapisan presisi, perawatan berkala sangatlah penting. Pada artikel ini, kita akan membahas beberapa tip perawatan untuk membantu Anda menjaga mesin penggulung lapisan presisi Anda berjalan dengan lancar.

Salah satu tugas perawatan terpenting untuk mesin penggulung lapisan presisi kawat adalah pembersihan rutin. Debu, kotoran, dan serpihan dapat menumpuk pada komponen mesin seiring berjalannya waktu, sehingga menyebabkan penurunan kinerja dan potensi kerusakan. Disarankan untuk membersihkan mesin setelah setiap kali digunakan, dengan memberikan perhatian khusus pada area di mana bahan dimasukkan ke dalam mesin dan tempat terjadinya penggulungan. Gunakan sikat lembut atau udara bertekanan untuk menghilangkan penumpukan dan memastikan semua bagian yang bergerak bebas dari penghalang.

Selain pembersihan, pelumasan adalah aspek penting lainnya dalam menjaga presisi mesin penggulung lapisan. Pelumasan yang tepat membantu mengurangi gesekan antar bagian yang bergerak, mencegah keausan dan memperpanjang umur mesin. Pastikan untuk menggunakan pelumas yang direkomendasikan untuk setiap komponen, dengan mengikuti pedoman pabrikan mengenai frekuensi dan kuantitas pengaplikasian. Periksa secara teratur bantalan, roda gigi, dan bagian bergerak lainnya untuk memastikan semuanya terlumasi dengan baik dan berfungsi dengan lancar.

Pemeriksaan rutin terhadap komponen mesin juga penting untuk mendeteksi tanda-tanda keausan atau kerusakan sejak dini. Periksa bagian-bagian yang longgar atau aus, seperti sabuk, katrol, dan roda gigi, dan gantilah sesuai kebutuhan. Periksa komponen kelistrikan mesin, seperti sensor dan motor, apakah ada tanda-tanda kerusakan atau panas berlebih. Mengatasi masalah dengan segera dapat mencegah masalah yang lebih signifikan dan menjaga mesin penggulung lapisan presisi Anda tetap beroperasi pada kinerja puncak.

Kalibrasi adalah tugas pemeliharaan penting lainnya untuk mesin penggulung lapisan presisi. Seiring waktu, pengaturan mesin mungkin menyimpang, sehingga mempengaruhi keakuratan proses penggulungan. Mengkalibrasi mesin secara teratur akan memastikan mesin menghasilkan gulungan yang konsisten dan presisi, memenuhi standar kualitas, dan meminimalkan limbah material. Ikuti instruksi pabrikan untuk prosedur kalibrasi dan jadwalkan pemeriksaan rutin untuk memastikan mesin beroperasi sesuai spesifikasi.

Terakhir, melatih operator Anda tentang perawatan dan pengoperasian mesin yang benar sangat penting untuk memaksimalkan kinerja mesin penggulung lapisan presisi Anda. Pastikan staf Anda memahami fungsi mesin, protokol keselamatan, dan prosedur perawatan. Dorong mereka untuk melaporkan masalah atau kelainan apa pun yang mereka amati selama pengoperasian, sehingga dapat segera diatasi. Berinvestasi dalam pelatihan dan dukungan berkelanjutan untuk operator Anda dapat membantu mencegah waktu henti yang mahal dan memastikan keandalan jangka panjang mesin penggulungan lapisan presisi Anda.

Kesimpulannya, perawatan rutin adalah kunci untuk memastikan kinerja optimal dan umur panjang mesin penggulungan lapisan presisi. Dengan mengikuti tips perawatan ini, Anda dapat menjaga alat berat Anda tetap berjalan lancar, meminimalkan waktu henti, dan memaksimalkan produktivitas. Ingatlah untuk membersihkan, melumasi, memeriksa, mengkalibrasi, dan melatih operator Anda secara rutin untuk menjaga mesin penggulung lapisan presisi Anda dalam kondisi prima. Dengan perawatan dan pemeliharaan yang tepat, alat berat Anda akan terus menghasilkan penggulungan yang akurat dan efisien selama bertahun-tahun yang akan datang.

Cara Memilih Mesin Winding Lapisan Presisi yang Tepat untuk Bisnis Anda

Mesin penggulung lapisan presisi adalah peralatan penting untuk bisnis yang membutuhkan penggulungan material seperti kawat, kabel, pipa, atau pita secara presisi dan efisien. Mesin ini dirancang untuk menggulung material ke gulungan atau gulungan dengan cara yang terkendali, memastikan ketegangan dan pelapisan yang seragam untuk kinerja optimal. Memilih mesin penggulung lapisan presisi kawat las yang tepat untuk bisnis Anda sangat penting untuk mencapai hasil berkualitas tinggi dan memaksimalkan produktivitas. Pada artikel ini, kita akan membahas faktor-faktor utama yang perlu dipertimbangkan ketika memilih mesin penggulung lapisan presisi yang memenuhi kebutuhan spesifik Anda.

Salah satu pertimbangan pertama ketika memilih mesin penggulung lapisan presisi adalah jenis bahan yang akan Anda lilitkan. Bahan yang berbeda memiliki sifat berbeda-beda yang dapat mempengaruhi proses penggulungan, seperti fleksibilitas, ketebalan, dan permukaan akhir. Penting untuk memilih mesin yang dirancang untuk menangani karakteristik spesifik material yang akan Anda kerjakan. Misalnya, jika Anda menggulung material yang halus atau rapuh, Anda mungkin memerlukan mesin dengan kontrol tegangan yang dapat disesuaikan untuk mencegah kerusakan selama proses penggulungan.

Faktor penting lainnya yang perlu dipertimbangkan adalah kecepatan dan kapasitas mesin penggulung lapisan presisi. Kecepatan mesin dalam menggulung material ke gulungan akan berdampak pada produktivitas bisnis Anda secara keseluruhan. Jika Anda memiliki kebutuhan produksi bervolume tinggi, Anda mungkin memerlukan mesin dengan kecepatan penggulungan lebih tinggi untuk memenuhi permintaan. Selain itu, kapasitas mesin, atau ukuran maksimum gulungan atau gulungan yang dapat ditampungnya, harus dipertimbangkan untuk memastikan mesin tersebut dapat menangani volume material yang perlu Anda anginkan.

Selain jenis material, kecepatan, dan kapasitas , penting juga untuk mempertimbangkan ketepatan dan keakuratan proses penggulungan. Mesin penggulung lapisan presisi dirancang untuk menggulung material dengan tegangan dan lapisan yang konsisten, yang penting untuk mencapai hasil berkualitas tinggi. Carilah mesin yang menawarkan kontrol presisi terhadap parameter belitan, seperti tegangan, kecepatan, dan pola pelapisan. Beberapa mesin mungkin juga dilengkapi teknologi canggih, seperti pengaturan yang dapat diprogram atau penyesuaian tegangan otomatis, untuk memastikan hasil penggulungan yang akurat dan berulang.

Saat memilih mesin penggulung lapisan yang presisi, penting juga untuk mempertimbangkan ketahanan dan keandalan mesin secara keseluruhan. Carilah mesin yang dibuat dengan bahan dan komponen berkualitas tinggi yang tahan terhadap kerasnya penggunaan terus-menerus. Selain itu, pertimbangkan reputasi pabrikan dan ketersediaan dukungan teknis serta layanan pemeliharaan untuk memastikan bahwa mesin Anda akan bekerja dengan andal dari waktu ke waktu.

Terakhir, pertimbangkan biaya keseluruhan mesin penggulung lapisan presisi, termasuk harga pembelian awal, biaya pengoperasian , dan potensi biaya pemeliharaan. Meskipun mungkin tergoda untuk memilih alat berat yang berbiaya lebih rendah untuk menghemat uang di muka, berinvestasi pada alat berat berkualitas tinggi yang memenuhi kebutuhan spesifik Anda pada akhirnya dapat menghemat waktu dan uang Anda dalam jangka panjang dengan mengurangi waktu henti dan meningkatkan produktivitas.

In Kesimpulannya, memilih mesin penggulung lapisan presisi yang tepat untuk bisnis Anda memerlukan pertimbangan yang cermat terhadap faktor-faktor seperti jenis bahan, kecepatan dan kapasitas, presisi dan akurasi, daya tahan dan keandalan, serta biaya keseluruhan. Dengan memilih alat berat yang memenuhi kebutuhan dan persyaratan spesifik Anda, Anda dapat memastikan hasil berkualitas tinggi, memaksimalkan produktivitas, dan mencapai kesuksesan jangka panjang dalam operasi penggulungan Anda.