Table of Contents

Selecting the Right Slip Wire Drawing Machine for Your Needs

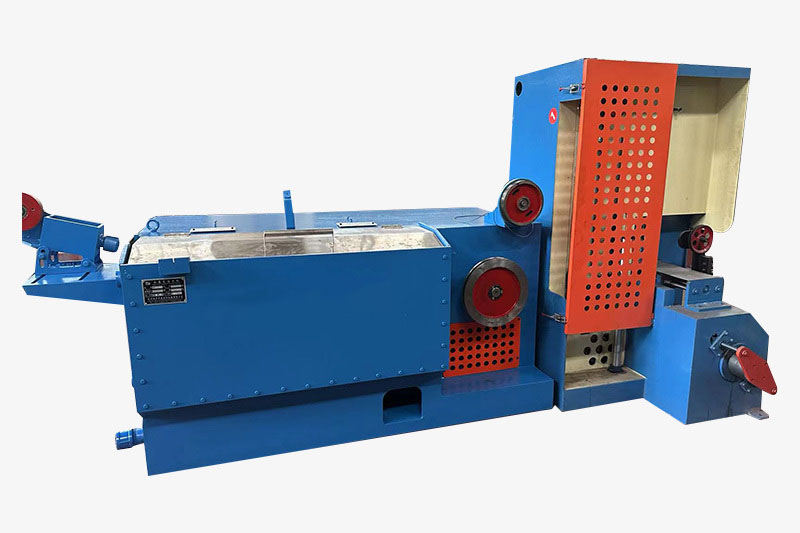

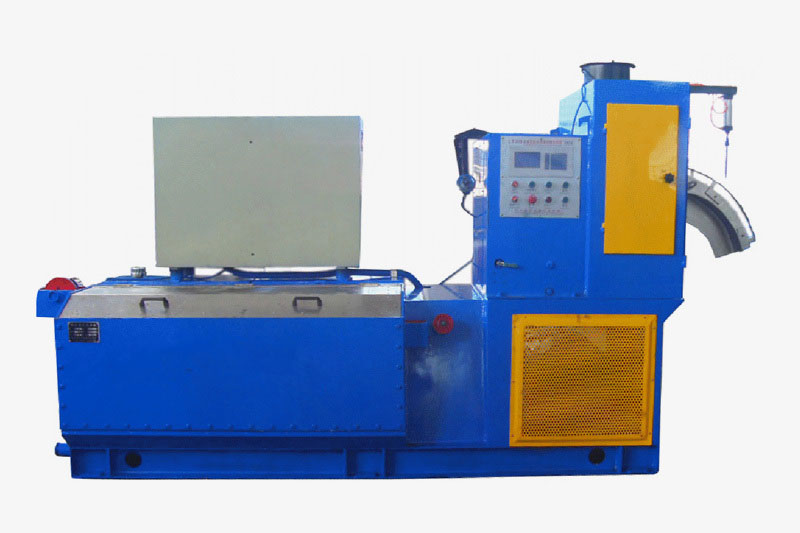

Slip Wire drawing machines are essential tools in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. This process is crucial for producing wires of various sizes and shapes, which are used in a wide range of applications, from electrical wiring to construction materials. If you are in the market for a wire drawing machine, it is important to select the right one for your specific needs.

When choosing a wire drawing machine, there are several factors to consider. The first step is to determine the type of wire you will be working with. Different machines are designed for different types of wire, so it is important to select a machine that is compatible with the material you will be using. Additionally, consider the diameter of the wire you will be working with, as this will impact the size of the machine you need.

Another important factor to consider is the speed at which you need the machine to operate. Some wire drawing machines are designed for high-speed production, while others are better suited for slower, more precise work. Consider your production needs and select a machine that can keep up with the demand.

It is also important to consider the number of dies the machine has. The more dies a machine has, the more times the wire can be drawn through, resulting in a finer wire. If you need to produce wires of varying diameters, a machine with multiple dies may be the best option for you.

In addition to these factors, it is important to consider the overall quality of the machine. Look for a machine that is well-built and durable, as this will ensure that it can withstand the rigors of daily use. Additionally, consider the reputation of the manufacturer, as a reputable company is more likely to produce high-quality machines.

Once you have considered these factors, it is time to select a wire drawing machine that meets your needs. There are many manufacturers that produce wire drawing machines, so take the time to research and compare different options. Look for machines that have the features you need at a price point that fits your budget.

When you have selected a machine, it is important to properly set it up and maintain it to ensure optimal performance. Follow the manufacturer’s instructions for installation and operation, and regularly inspect and clean the machine to prevent any issues from arising.

In conclusion, selecting the right Wet Wire Drawing Machine is crucial for producing high-quality wires efficiently. Consider the type of wire you will be working with, the speed at which you need the machine to operate, the number of dies it has, and the overall quality of the machine. Take the time to research and compare different options before making a decision, and be sure to properly set up and maintain the machine for optimal performance. With the right wire drawing machine, you can produce wires of various sizes and shapes to meet your specific needs.

Step-by-Step Guide to Building Your Own Wire Drawing Machine

Wire drawing machines are essential tools for creating wire of various diameters and lengths. These machines are commonly used in industries such as manufacturing, construction, and electronics. While purchasing a wire drawing machine can be costly, building your own machine can be a cost-effective alternative. In this article, we will provide a step-by-step guide on how to build your own wire drawing machine.

The first step in building a wire drawing machine is to gather all the necessary materials and tools. You will need a sturdy frame to support the machine, a motor to power the machine, a wire drawing die, and various pulleys and gears to control the speed and tension of the wire. Additionally, you will need wire of the desired diameter to draw through the machine.

Once you have gathered all the materials and tools, the next step is to assemble the frame of the wire drawing machine. The frame should be strong and stable to support the weight and force of the machine. You can use metal or wood to construct the frame, depending on your preference and availability of materials.

After assembling the frame, the next step is to install the motor that will power the machine. The motor should be securely attached to the frame and connected to the pulleys and gears that will control the speed and tension of the wire. It is important to ensure that the motor is properly aligned and calibrated to prevent any malfunctions during operation.

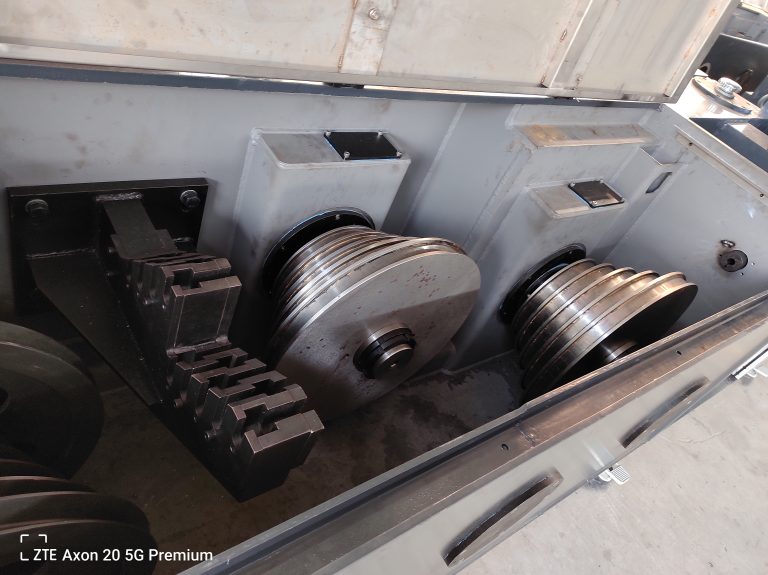

Once the motor is installed, the next step is to install the wire drawing die. The wire drawing die is a crucial component of the machine that shapes the wire as it is drawn through the machine. The die should be securely attached to the frame and aligned with the pulleys and gears to ensure smooth operation.

After installing the wire drawing die, the next step is to set up the pulleys and gears that will control the speed and tension of the wire. The pulleys and gears should be properly aligned and calibrated to ensure that the wire is drawn through the machine at the desired speed and tension.

Finally, the last step in building a wire drawing machine is to test the machine to ensure that it is functioning properly. You can test the machine by feeding wire through the machine and observing the output. If there are any issues or malfunctions, you can troubleshoot and make adjustments as needed.

In conclusion, building your own wire drawing machine can be a cost-effective alternative to purchasing a pre-made machine. By following this step-by-step guide, you can build your own machine and create wire of various diameters and lengths for your specific needs. Building a wire drawing machine requires careful planning, assembly, and testing to ensure that the machine functions properly. With the right materials, tools, and knowledge, you can successfully build your own wire drawing machine and enhance your manufacturing capabilities.